Table of Contents

How is graphite powder made?

| Type | Crystal grain size | Origin |

| Earthy graphite | 0.01~0.1μm | Türkiye, Europe, China, Mexico and the United States |

| Flake graphite | 0.05~1.5 mm | Australia, Brazil, Canada, China, Germany and Madagascar |

| Block graphite | >0.1 mm | Sri Lanka |

Graphite powder is an industrial fine powder processed from graphite ore. It is processed through 5 processes:

- Crushing. Graphite ore is crushed into fragments.

- Grinding. The fragments are ground into powder with a particle size of 20~1000 microns.

- Drying. Reduce the moisture content in the powder to below 4% to prepare for screening.

- Screening. Obtain graphite powder of different particle size ranges.

- Packaging. Graphite powder of different particle sizes is packaged and put into the warehouse.

Challenges of graphite screening

1. The requirements for powder particle size are becoming increasingly stringent. With the change and development of technology, various industries have increasingly stringent requirements for the particle size of graphite powder, especially as graphite is an important raw material for lithium batteries. Graphite with finer particle size will undoubtedly increase its application value. The traditional screener machines can screen graphite powder with a fineness of 100 microns (100 mesh) very smoothly. When the mesh size is reduced to 75 microns or even 45 microns, the screening efficiency becomes extremely low.

2. The purity of graphite is also very important. In the high-temperature purification process, because the boiling point of graphite is a terrifying 3700 degrees Celsius, the temperature of the purified graphite is terrifyingly high. Even the temperature of the graphite powder after drying is above 100 degrees Celsius. High-temperature graphite will burn through the wire mesh screen which is as thin as a hair in a short time. Frequent replacement of the screen not only increases production costs, but also increases downtime.

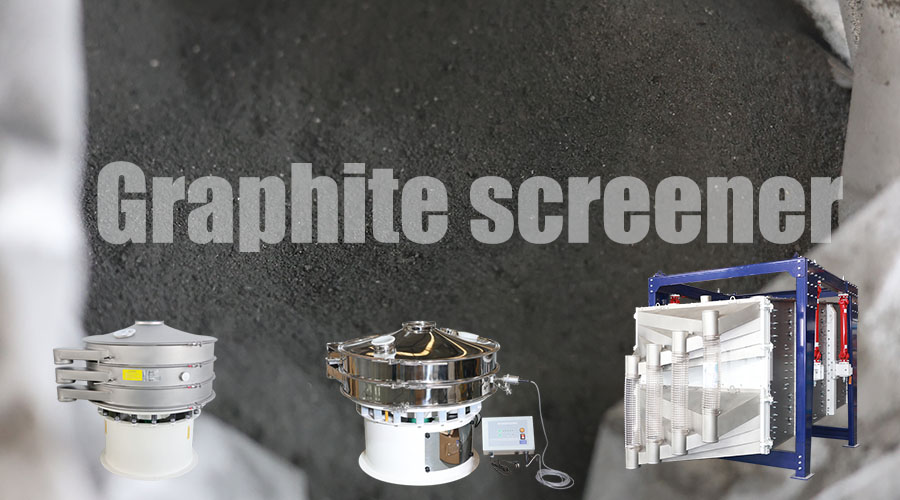

graphite screeners

We have four types of screeners, vibrating sieve, ultrasonic vibrating sieve, and gyratory screener. They are responsible for screening graphite of different particle size ranges, with an output ranging from 100kg/hour to 10 tons per hour, fully meeting the needs of different graphite production lines.

| Screener types | Screen size mm | Temperature limit ℃ | Mesh size range Microns | Capacity range ons per hour |

| Circular vibrating sieve | Dia. 1200 | 120 | 100~2000 | 1~3 |

| Large capacity vibrating screen | 2000*3600 | 120 | 1000~10000 | 1~40 |

| Ultrasonic vibrating sieve | Dia. 1200 | 50 | 40~300 | 0.2~1 |

| Gyratory screener | 2000*3600 | 80 | 40~300 | 3~10 |

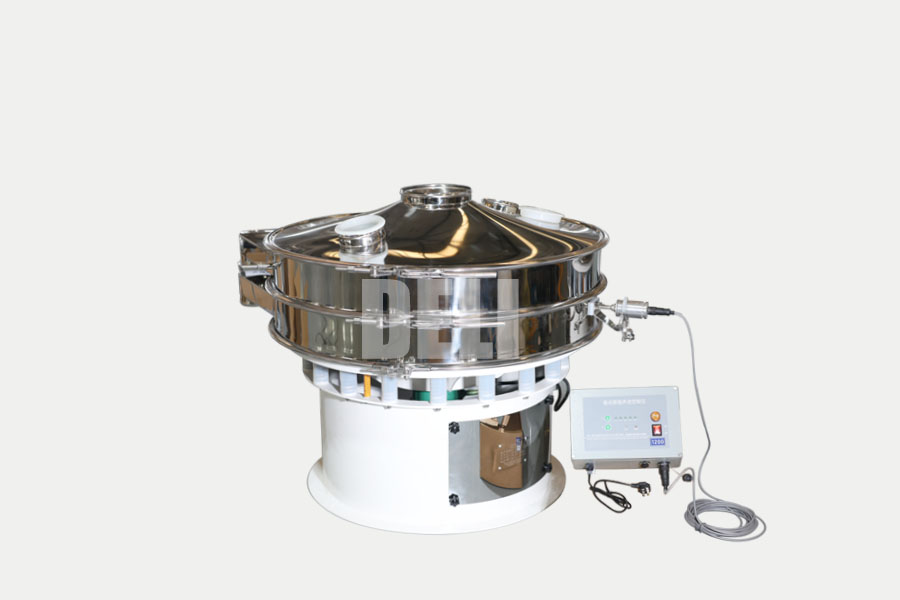

graphite vibrating sieve

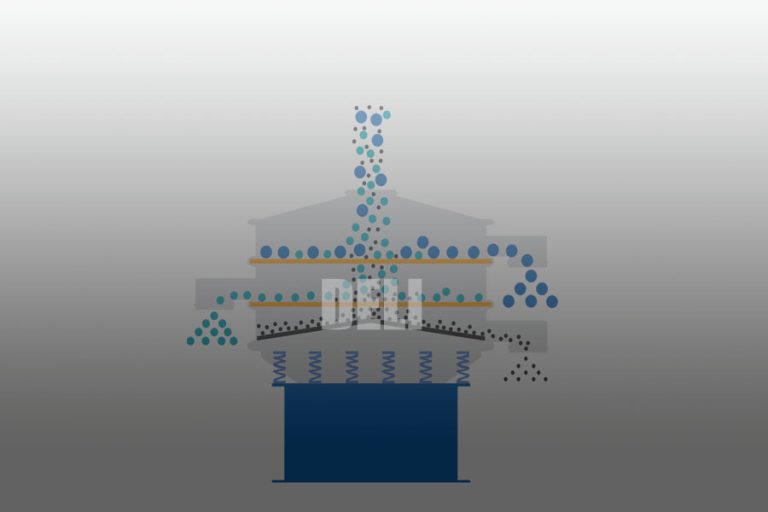

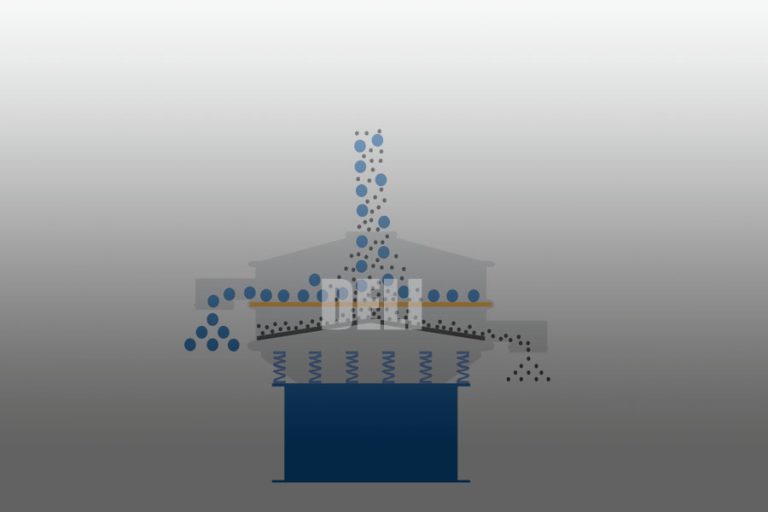

It uses the principle of vibration to separate graphite powder into products of different sizes.

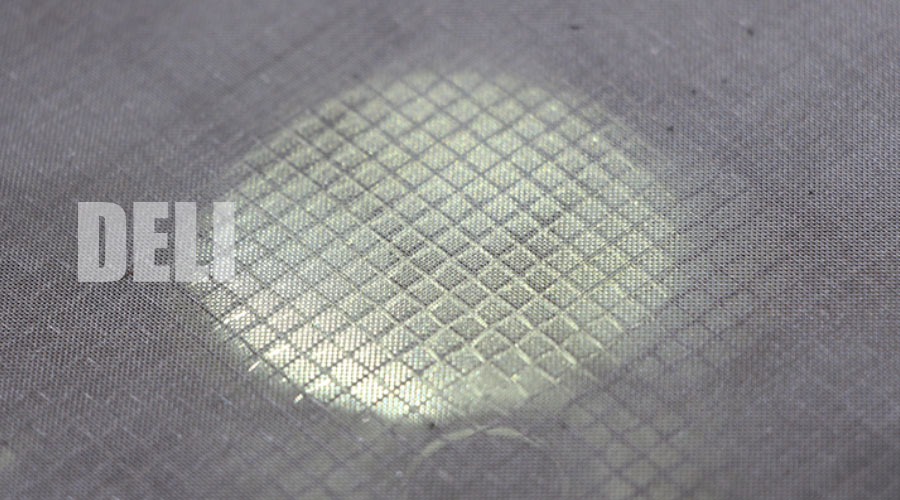

The biggest advantage of the vibrating sieve machine is that it uses all-metal material and composite screen, so it can work at a high temperature of 120 degrees Celsius, and the life of the screen can be guaranteed.

Ultrasonic vibrating sieve

This product can tell 30 microns ultra-fine powder, which meets most manufacturers requirement for particle size.

When the mesh size drops below 75 microns, the powder will clog the mesh and the screening will become very slow, which obviously cannot meet the demand for output and efficiency of industrial production. DELI applies ultrasonic vibration to the vibrating sieve, and the 36GHZ high-frequency vibration will be transmitted to each mesh to remove the particles that clog the mesh and improve the sieving efficiency.

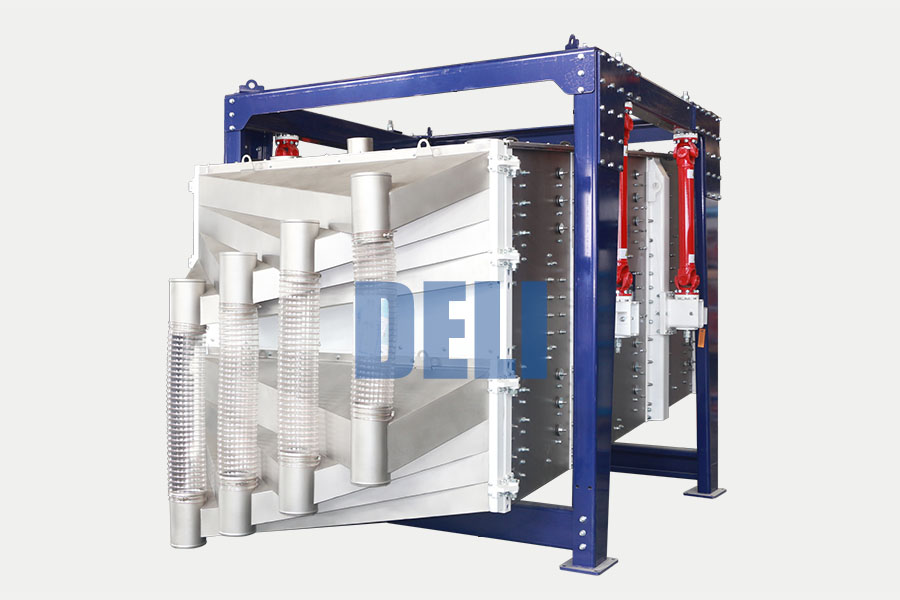

Graphite Screener

The graphite powder tumbles along an elliptical trajectory on the screen surface instead of being thrown up like a vibrating sieve, so the powder stays in contact with the screen surface for a longer time and gets more screening opportunities, which is why the DELI graphite screener can simultaneously meet the requirements of identifying 45 micron powders and a production capacity of up to 10 tons per hour.

Watch the video to learn how the screener works.

The effect of vibration sieve on graphite processing

Natural graphite minerals have the characteristics of irregular shape and high hardness. The role of the vibrating sieve for graphite products is to classify the particle size, because graphite has a wide range of uses, such as refractory materials, corrosion-resistant materials, conductive materials, etc. Different uses have different requirements for the particle size of graphite, so the particle size of graphite is an important indicator for the application of graphite products.

More precise particle size and less impurities are an important competitive advantage of high-quality graphite products. Our graphite vibrating sieve uses core components from internationally renowned brands and a structural design that has been verified in the market for more than 10 years, which can bring less downtime, long service life and simple maintenance to graphite processing plants.