company introduction

DELI INDUSTRIAL LIMITED is vibro sifter supplier in China, we design and manufacturing vibrating screener machines.

Our company was established in 2013 and has more than 100 experienced employees in the manufacturing base. The factory has an annual delivery capacity of 5,000 sets.

Delivery time of Vibro Sifter Supplier

Stable delivery time enhance customers’ market competitiveness.

Good supply chain management capabilities shorten delivery time. DELI has a complete supply chain management system. After receiving the customer’s order, our design department, production department, procurement department, and logistics department will quickly receive information through the computer management system, so that information can flow quickly. At the same time, CNC laser cutting machines, bending machines, welding robots and other automated equipment provide manufacturing speed. These systems and hardware ensure that customers receive the vibro separator within the agreed time.

DELI Pursue Long-Term Cooperative Relationship With You.

As a powder vibratory sieve machine factory in China, we are most proud of the fact that we have established cooperation with multiple customers for more than 10 years. Customers think we are trustworthy and we are happy to listen to any opinions from customers. This is the cooperative state we pursue. We are willing to move forward with customers and establish a win-win cooperation.

long-term cooperation

Story with one of customers

One spring in 2020, V from Malaysia sent an inquiry, V is looking for a gyratory screener manufacturer in China.

V said he wanted a linear vibrating sieve . He valued the convenience of screen replacement and the mesh remind performance.

Then we sent a quotation as required and recommended two other linear vibrating screen to V.

V expressed great interest, and we started a video conference to learn more about V’s factory layout and sifting requirements.

In the end, I sent a 10-page quotation to V.

But V is a cautious decision maker.

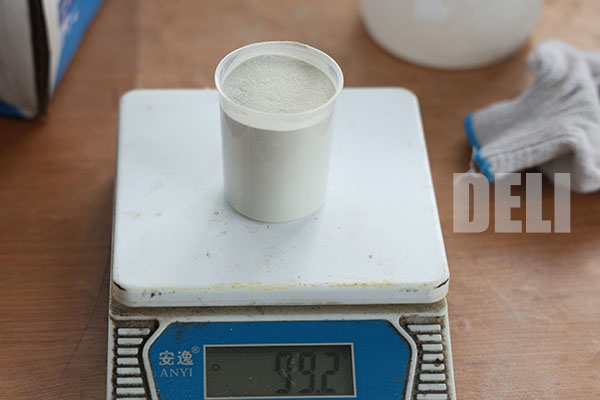

So, V sent a ton of material, and we carried out field tests, and the tests proved that the sifter could achieve a production of 2 tons and a screening accuracy of 99.99%.

Three months after receiving the inquiry, V decided to start purchasing, and this was just the beginning of our 10-year relationship.

Quality control

We deliver durable vibratory screener to our customers.

The vibration sieving machine received by customers is durable and of guaranteed quality.

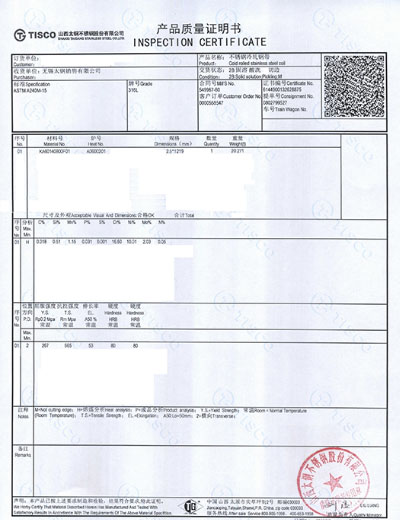

We implement DELI quality inspection standards from the purchase of raw materials. The raw materials, processing, assembly and packaging of the equipments must meet the quality standards before they can be approved for shipment.

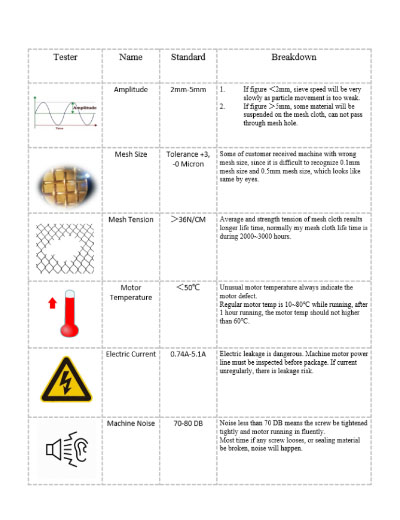

Quality inspection system:

1. ISO9001 standard system.

2. Incoming material inspection.

3. Parts circulation card.

4. Sheet metal processing inspection.

5. Appearance inspection standards.

6. Quality standards before shipment.

Quality standard

| NO. | Item | Standard |

| 1 | Amplitude | 3mm-5mm |

| 2 | Mesh Size | +3 ~ -0 Micron |

| 3 | Mesh Tension | >30N/CM |

| 4 | Motor Temperature | <50℃ |

| 5 | Electric Current | 0.74A-5.1A |

| 6 | Machine Noise | 70-80 Db |