Table of Contents

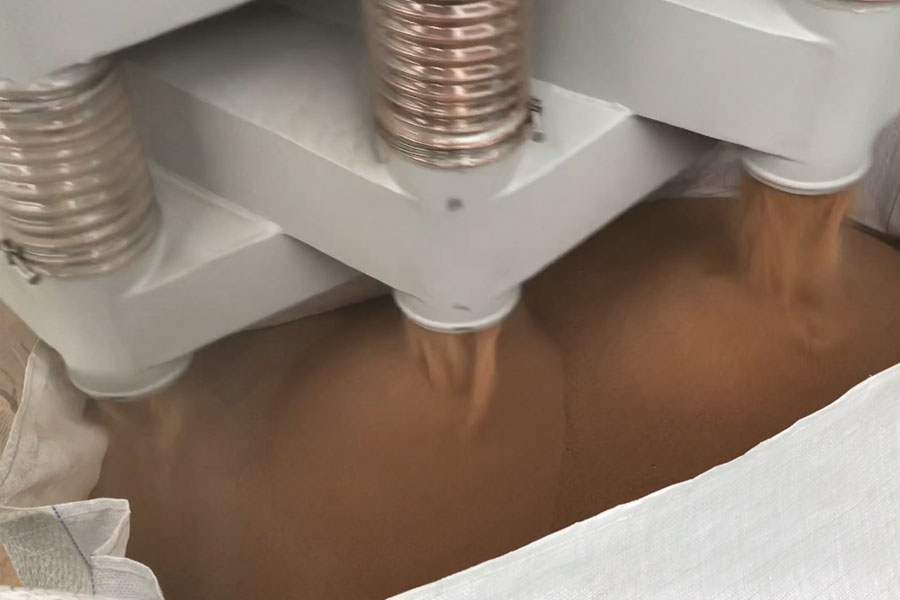

quartz sand gyratory screening equipment use

It is mainly used for quartz sand size separating. Because quartz sand has the problem of inconsistent particle size after crushing or grinding, that is, quartz sand of different particle sizes are mixed together. At the same time, users of quartz sand have different requirements for particle size, which requires quartz sand factories to need a screening machine which can separate quartz sand into products of various particle sizes.

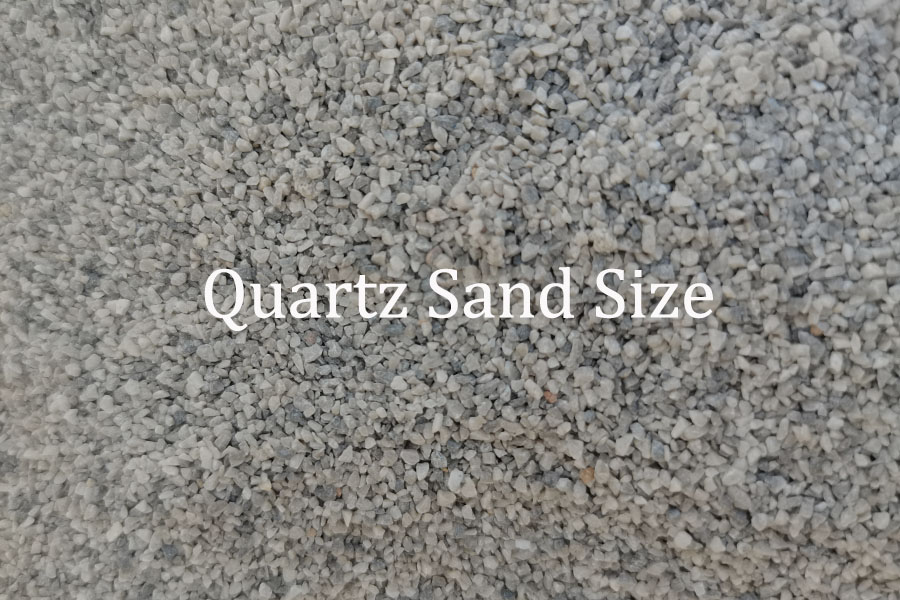

The importance of quartz sand size

Size affects the competitiveness of quartz sand in the market. To be precise, the accuracy of quartz sand size affects the competitiveness of quartz sand. Let me give two examples:

An oil field needs a kind of 70-140 mesh quartz sand as fracturing proppant. Based on the oil well depth and oil and gas flow efficiency, they calculated that 70-140 mesh quartz sand is the target product. At this time, they will evaluate whether the size of the quartz sand is accurate, that is, how much wrong-sized quartz sand (we call it “impurities”) is contained in the 70-mesh to 140-mesh quartz sand. For example, the product contains more than 10% of 200-mesh quartz. The sand leads to a decrease in oil and gas flow efficiency, ultimately leading to a decrease in oil field production. The more complete the screening, the less “impurities”, and the higher the competitiveness of quartz sand products. This is the role of a good vibrating screen.

A foundry purchases quartz sand for the production of sand molds. Because of the breathability of the mold, the foundry needs to mix quartz sand of different sizes in a certain proportion and then make the mold. The precise size of high-quality quartz sand ensures that the particle size ratio in foundry sand is closer to the theoretical value, making it more competitive.

Advantages of using gyratory screen to screen quartz sand

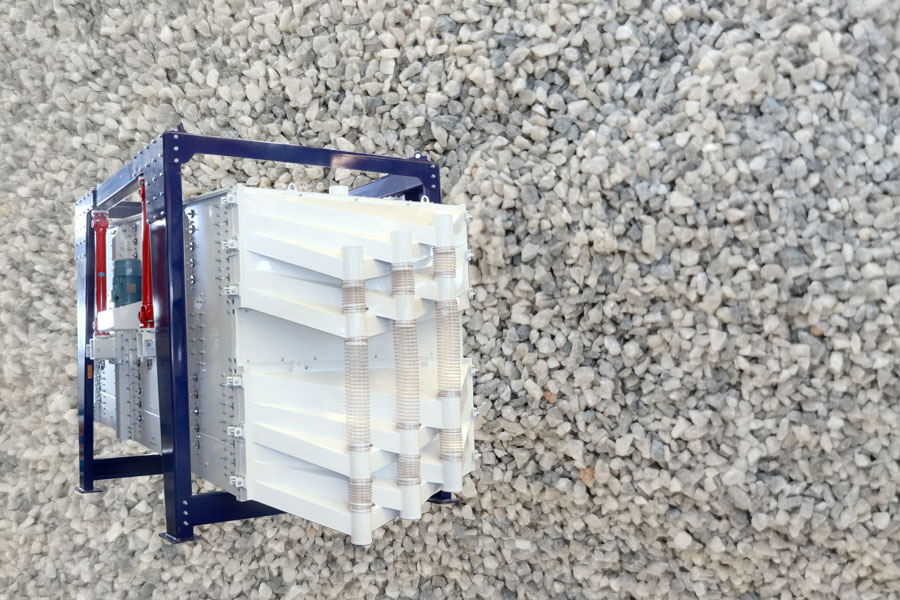

There are many kinds of vibrating screens that can screen quartz sand. Please visit the classification of vibrating screens. The gyratory screening machine has the advantages of high efficiency and simple maintenance.

- Hign efficiency.

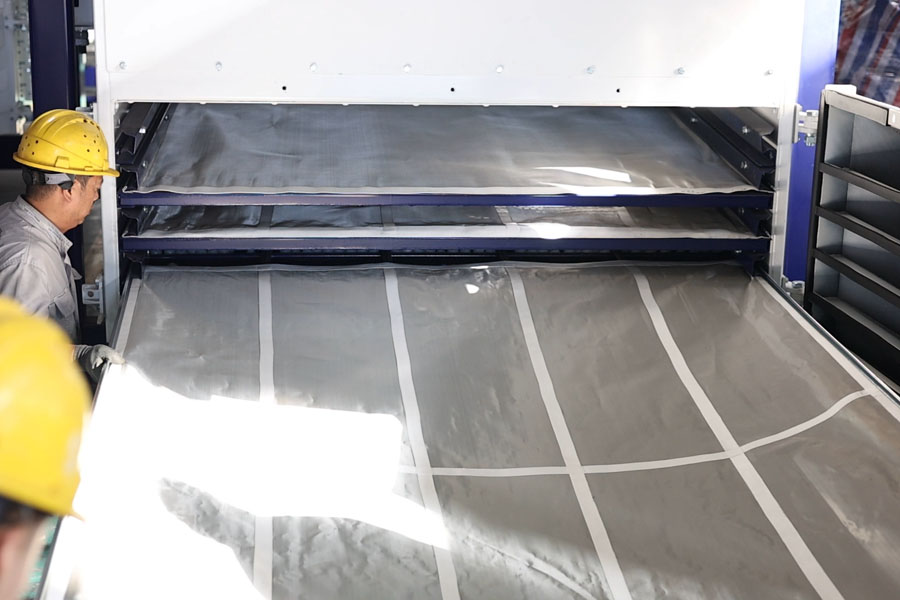

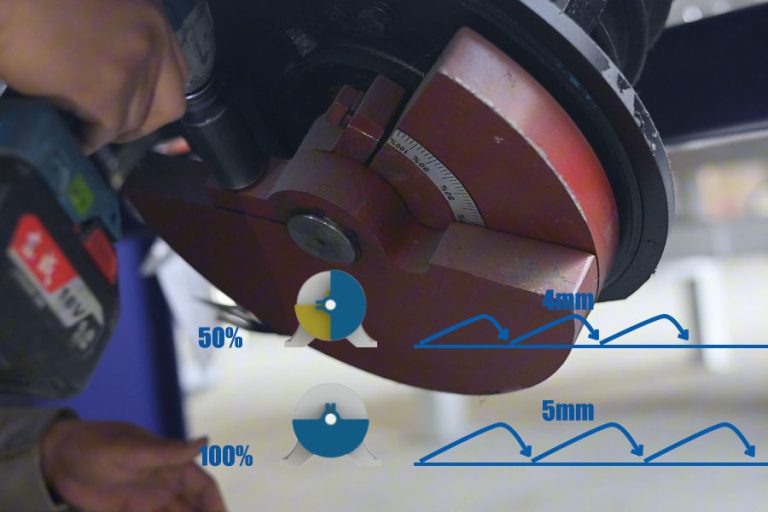

Thanks to the curved motion trajectory, the quartz sand stays on the screen surface for a longer path during the screening process and can be more fully screened. Therefore, the dimensional accuracy of the finished quartz sand reaches 99%. - Maintenance is simple. Maintenance of equipment incurs labor costs and increases downtime. The gyratory screen adopts a quick access design, so customers can complete screen maintenance and replacement in a shorter time, which greatly saves customers maintenance costs.