Table of Contents

Lithium battery materials vibrating sieve

Thanks to the surge in sales of electric vehicles, the application of lithium batteries has exploded in the past few years. Vibrating sieve machine can be used to seprate lithium battery cathode materials and lithium battery anode materials.

Lithium battery cathode materials vibration sieve

The following table shows common lithium battery cathode materials:

| Cathode Materials | Chemical composition | Structure |

| Lithium cobalt oxide (LCO) | LiCoO2 | Layered |

| Lithium manganese oxide (LMO) | Li2Mn2O4 | Spinel |

| Lithium nickel oxide (LNO) | LiNiO2 | Layered |

| Lithium iron phosphate (LFP) | LiFePO4 | Olivine |

| Nickel cobalt aluminum (NCA) | LiNixCoyAl(1-x-y)O2 | Layered |

| Nickel cobalt manganese (NCM) | LiNixCoyMn(1-x-y)O2 | Layered |

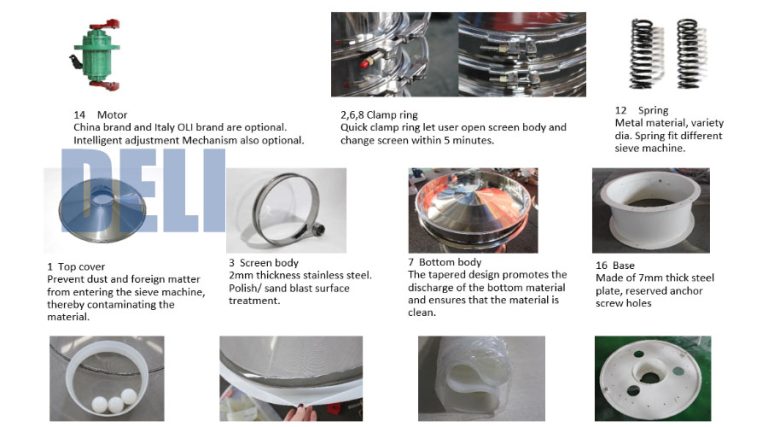

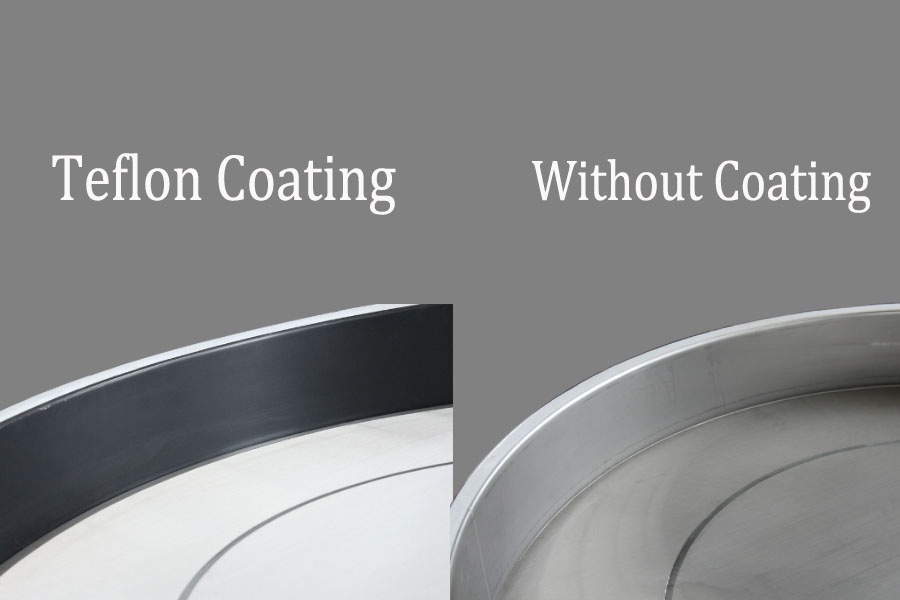

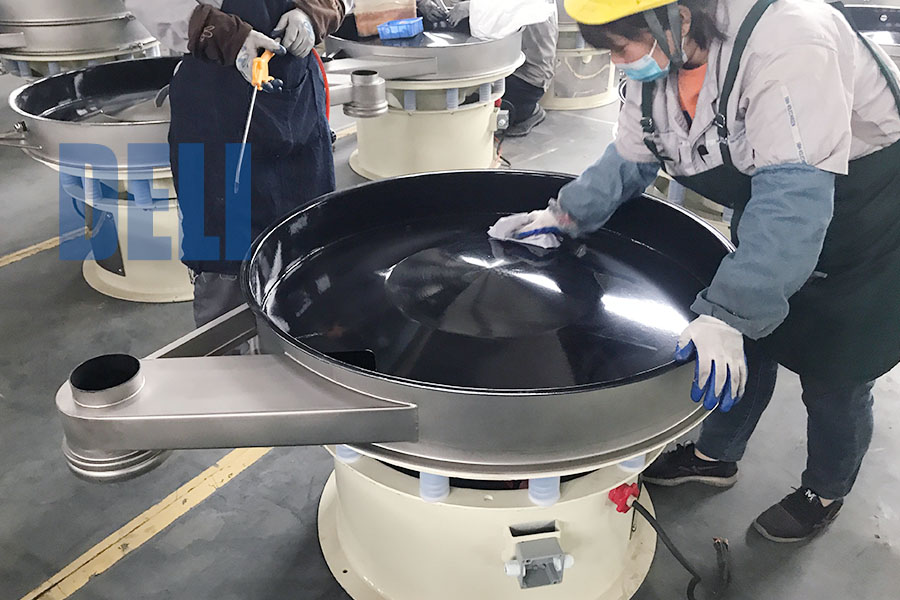

The cathode materials cannot contact the metal material, which is the most important requirement in the screening process.

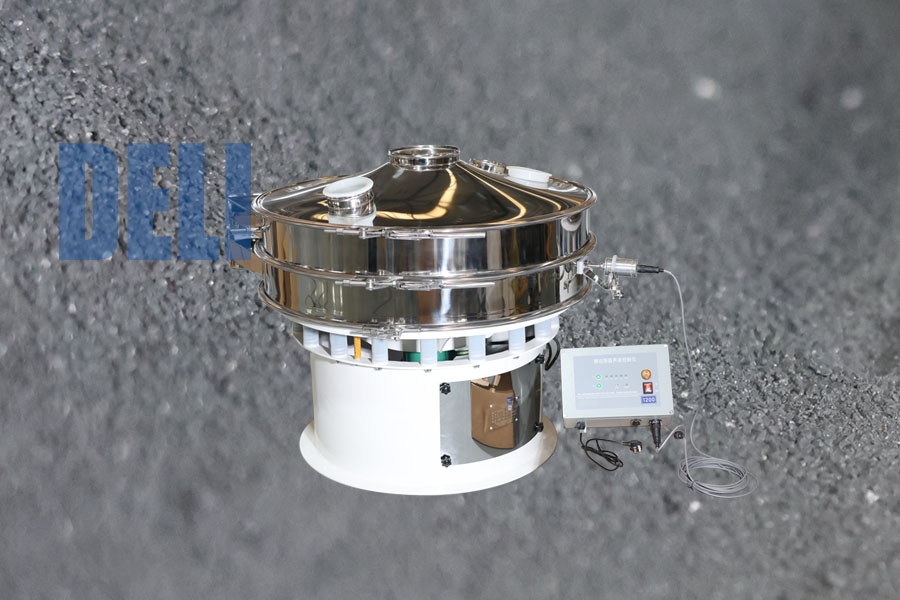

Our vibrating sieve machine uses Teflon coating, which acts as an insulator. The parts of the vibrating screen that contact the cathode material powder are all Teflon coated.

The ternary negative electrode materials of lithium batteries are separated using meshes ranging from 100 to 325 meshes to obtain fine powder. We recommend using an ultrasonic cleaning system to improve screening efficiency. The ultrasonic vibrating sifter can separate 200kg of ternary materials per hour under the condition of a 325 mesh.

anode materials vibration sieve

Graphite is a common negative anode material for lithium batteries, and its screening requires high output. For details, please see the graphite vibrating sieve article.