Table of Contents

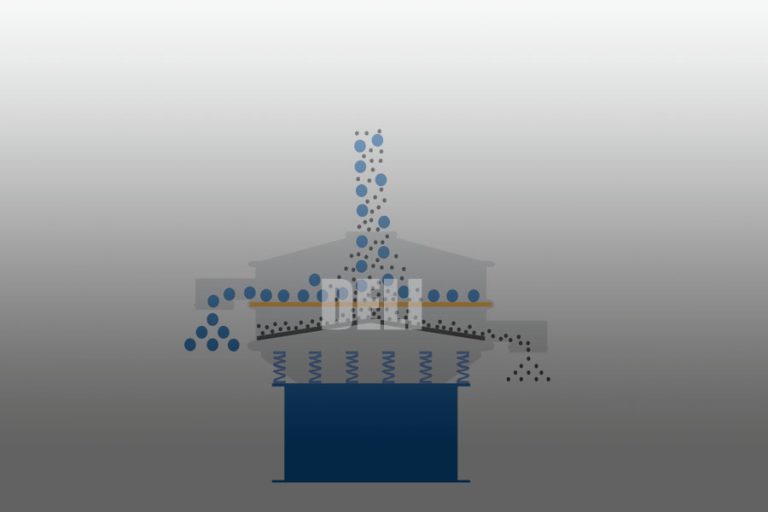

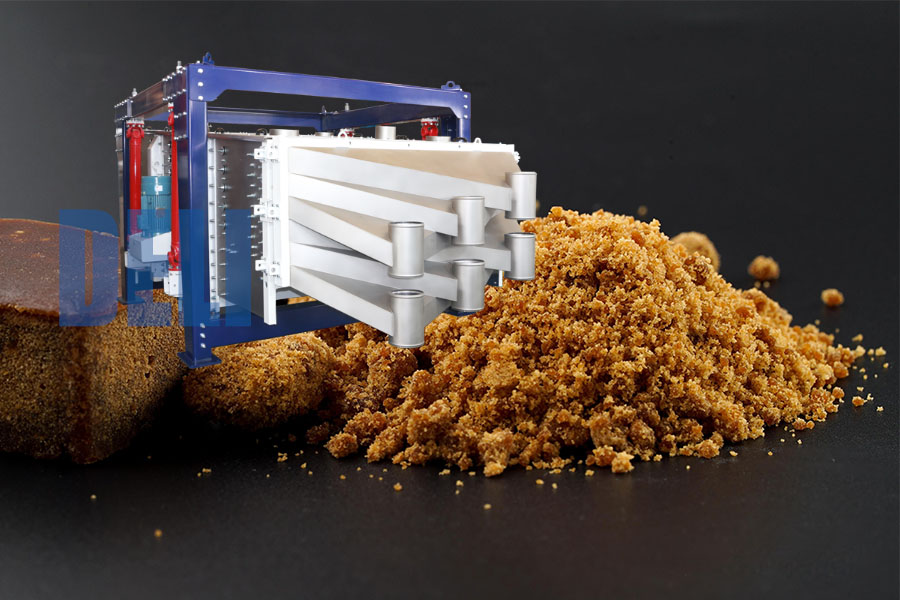

sugar vibratory separator working principle

The sugar vibratory separator uses the principle of physics to separate sugar into products of different sizes. Sugar smaller than the mesh will pass through the mesh and enter the next layer of the sieve, while sugar larger than the mesh will remain on the mesh screen, and you will eventually get sugar of different particle sizes.

Because sugar powder with a mesh size smaller than 50 is very fine, and sugar factories often require vibrating separation equipment to have a higher output, sugar separation faces a problem: the efficiency of traditional vibrating screens for screening sugar with a mesh size smaller than 50 is very low, and it is difficult to simultaneously meet the two conditions of high output and small mesh size.

Our Gyratory screening machine uses a unique elliptical running track design and a larger swing amplitude to improve the screening efficiency of fine powders. A single device can achieve an output of 20 tons (using a 50-mesh mesh).

vibratory separator position in sugar processing

The production process of sucrose sugar is sugarcane cutting, juicing, clarification, cooking and dehydration, filtration, decolorization, crystallization, drying, separating and packaging. The position of the sugar vibratory separator in the sugar production process is after drying and before packaging. The role of the vibration separator in the processing process is to separate the finished sugar particles into sugars of different particle sizes. The separated sugar will be packaged and put into the market.

Technical parameters of Vibration sieve

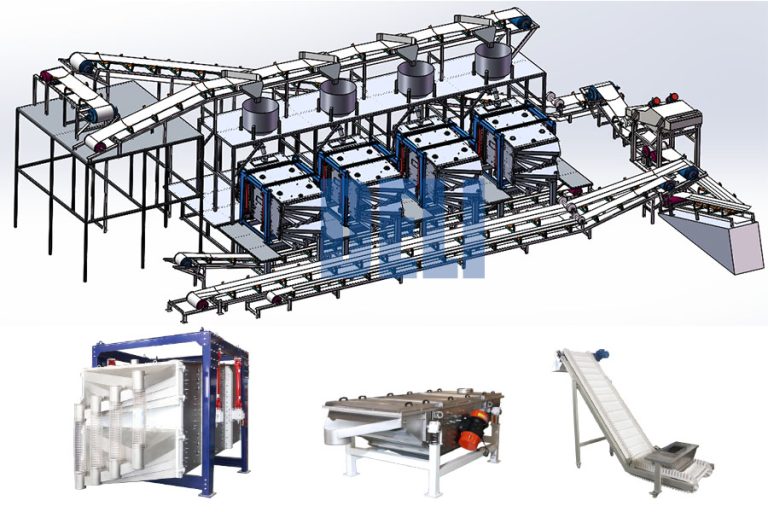

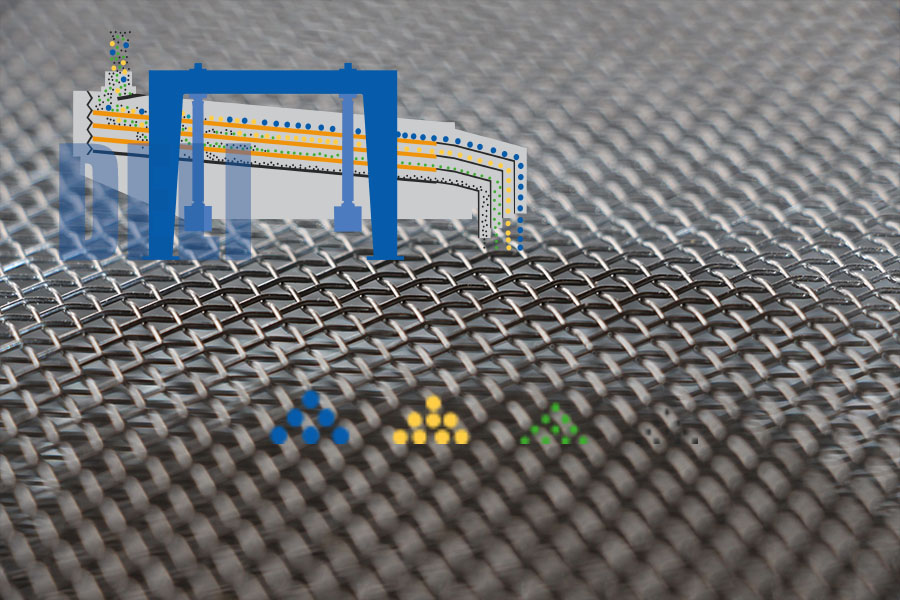

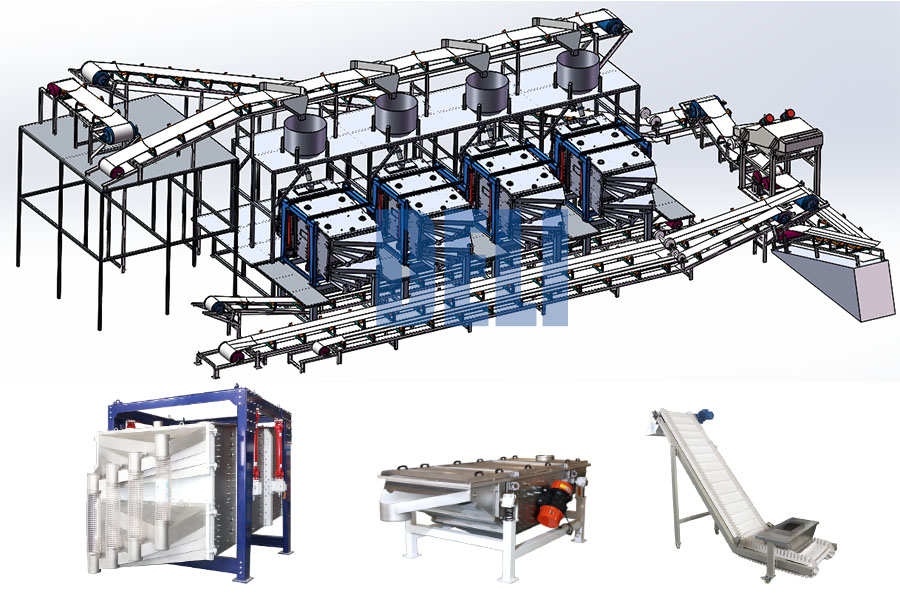

For sugar plants, the output of the vibrating separator is particularly important. The popular separation scheme is to use two sieving equipments for twice separating processes. The first vibration sifter is a linear vibrating sieve, which uses a larger mesh size to remove large sugar particles and agglomerates, and pre-treat the sugar raw materials. The second vibration sifter is a gyratory screener, which is used to screen the finished product.

The following are the technical parameters of the vibrating sieve machines.

| Machine Name | Linear vibrating sieve |

| Capacity / Tons per hour | 100 |

| Mesh size / MM | 5 mesh (4mm) |

| Screen layers | 1 |

| Machine power / KW | 5.5 * 2 |

| Usage: | Remove lumps and improve the efficiency of the gyratory screening machine. Sugar raw materials with less than 5 mesh will enter the gyratory screen. |

| Machine Name | Gyratory screener |

| Screen layers | 2 |

| Capacity / Tons per hour | 20 |

| Mesh size / MM | 16 mesh, 50 mesh (1.18mm, 0.3mm) |

| Product 1 | bigger than 16 mesh |

| Product 2 | 16 ~ 50 mesh |

| Product 3 | smaller than 50 mesh |

| Machine Price: | $21,600 |

Contact our expert to get the solution and quotation.