Table of Contents

sifter balls

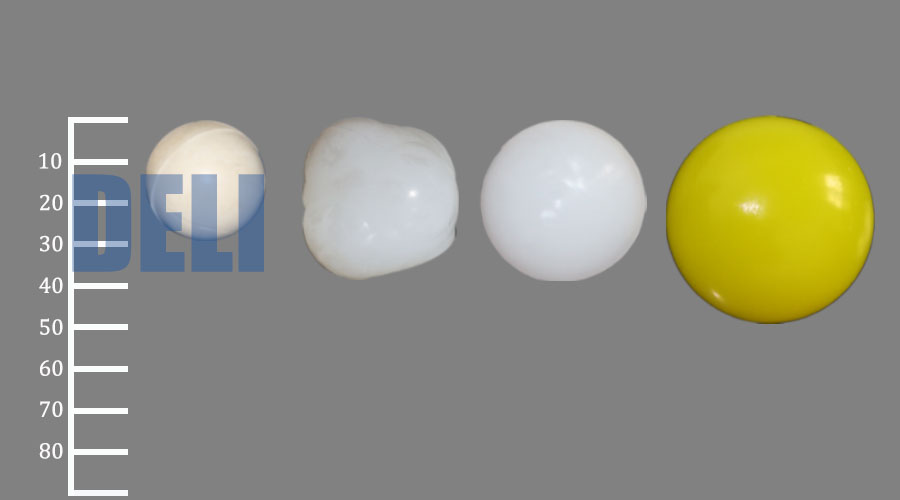

Sifter balls are a kind of wearing parts in vibration sifter equipment, which are used to clean the mesh and improve the sifting efficiency. The diameter of the ball ranges from 10mm to 80mm, and the materials include rubber, silicone and polyurethane.

| Vibration sifter ball types | Material | Size/mm | Shore Hardness | Resilience/% |

| Polyurethane ball | Polyurethane | 30 ~ 80 | 50~80 | 50~70 |

| Rubber ball | Rubber | 20 ~ 40 | 30~70 | 50~70 |

| Silicone ball | Silicone | 20 ~ 40 | 20~50 | 70~80 |

| Special shape ball | Silicone | 20 ~ 40 | 20~50 | 70~80 |

Choosing Rebound ball for the vibrating sifer

First, we have three principles to help you quickly understand the characteristics of the jump ball:

1. The higher the hardness, the higher the wear resistance.

2. The higher the hardness, the worse the rebound performance.

3. The higher the rebound performance, the better the net clearing effect.

Secondly, choose the ball according to the mesh size. The following table shows the mesh sizes that are suitable for different bouncing balls.

| Rebound ball types | Particle size/mm | Vibration sieve | Industries |

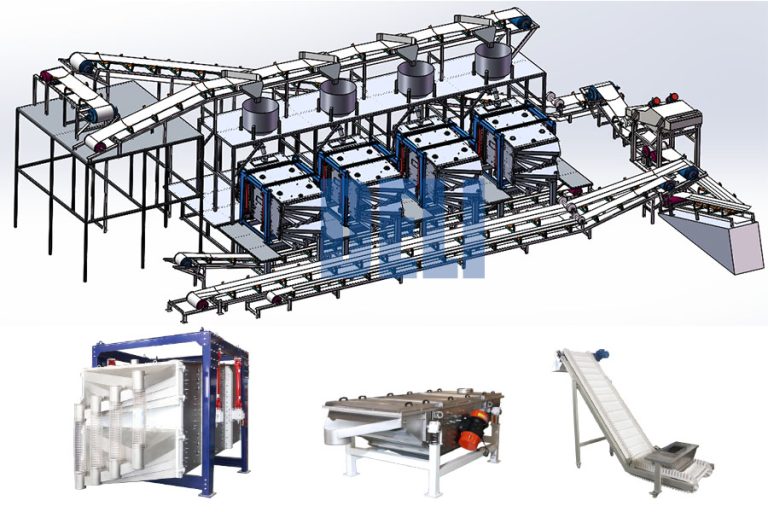

| Polyurethane ball | 10~50 | Linear vibration screen | Minerals, Large particle products |

| Rubber ball | 0.5~10 | Linear vibration sieve | Minerals, granule and powder |

| Silicone ball | 0.1~4 | round vibro sifter, gyratory screener, tumber screener, linear vibration sieve | Food, Chemical, Agriculture, Fine Powder |

bouncing Ball materials

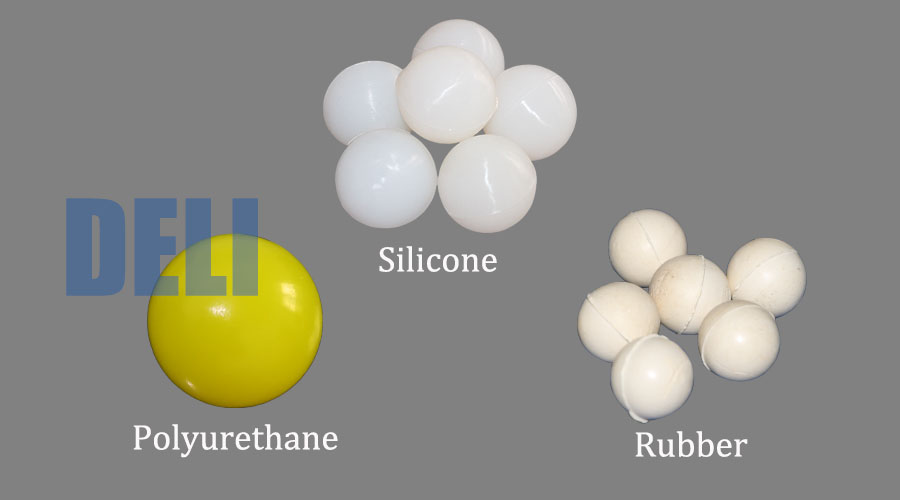

According to the raw materials for making balls, there are three types of balls:

Rubber balls

The main material is rubber, usually white or black. Its advantages are low price and average bounce performance.

Silicone balls

Made of silicone, milky white. The price is slightly higher, with excellent rebound performance and qualified wear resistance. Silicone is a food contact grade material, so this jump ball can be used in vibrating screens in the food industry.

Polyurethane balls

The characteristics of polyurethane material are super high wear resistance and durability. It has the lowest rebound performance. Mainly used in the field of mineral screening.

Hardness and rebound height test

We test the rebound height of different balls. This is the test result of the first rebounce height:

Hardness 65 ball: 70cm

Hardness 75 ball: 58cm

Hardness 80 ball: 55cm

Ball diameter

The maximum diameter of the ball can reach 80mm, and this value usually depends on three dimensions: mesh size, material hardness and vibrating screen type.

The diameter of the ball must be larger than the mesh size. For example, if the mesh size of the vibrating screen is 10mm, then the diameter of the ball must be at least 20mm.

For screening large particles with high hardness, polyurethane balls are limited. For example, the wear of quartz particles on the jump ball is catastrophic. The polyurethane material can be used for a longer time, saving user costs.

For fine powder vibrating screens, 30mm silicone jump balls are recommended.

Function of the vibration sieve balls

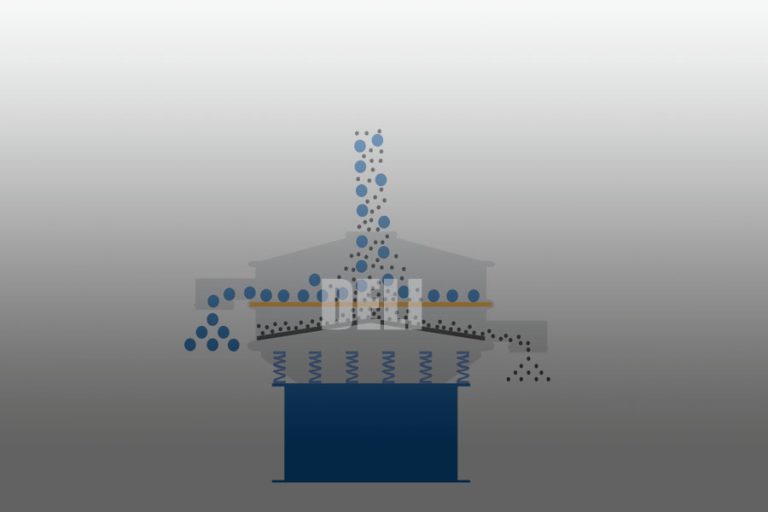

The ball is the necessary parts of the vibration sieve machine, which is placed on a steel plate below the screen mesh. When the vibration sieve is running, the ball bounces between the steel plate and the screen, hitting the screen net to clear the material that is blocking the net, ultimately ensuring that the mesh hole is always in an open state, allowing the material to pass through the mesh quickly and improve sieving efficiency.