Table of Contents

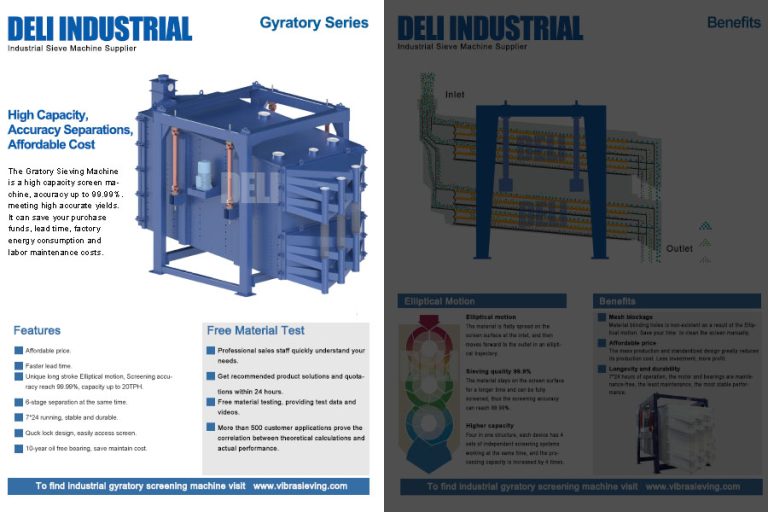

Industrial Flour Sifters Improve the product Quality

Industrial flour sifters are essential tools for improving the quality of various flour products. By sifting flour, users can remove lumps, clumps, and other impurities that can affect the texture and flavor of their products. Additionally, sifting flour helps to aerate it, which can improve the rise and texture of the finished product.

The traditional screening method is to add a layer of wire mesh or grate bars under the grinding equipment. However, the net in this way is fixed and does not cause any movement. Considering that the moisture content of flour is usually around 14%, and the flour contains larger particles that are not fully ground, the flour after grinding is prone to clogging. mesh. Additionally, the grates are usually spaced far apart, making it difficult to provide you with high-quality, fine flour.

In comparison, the flour screener is equipped with a bouncing ball self-cleaning device under the screen mesh, which allows the mesh to remain open at all times and completely solves the problem of hole blocking.

DELI vibrating screen allows users to sift flour under 50 mesh (300 micron) mesh conditions to obtain fine flour with a particle size of less than 300 microns, improving the quality of users’ flour.

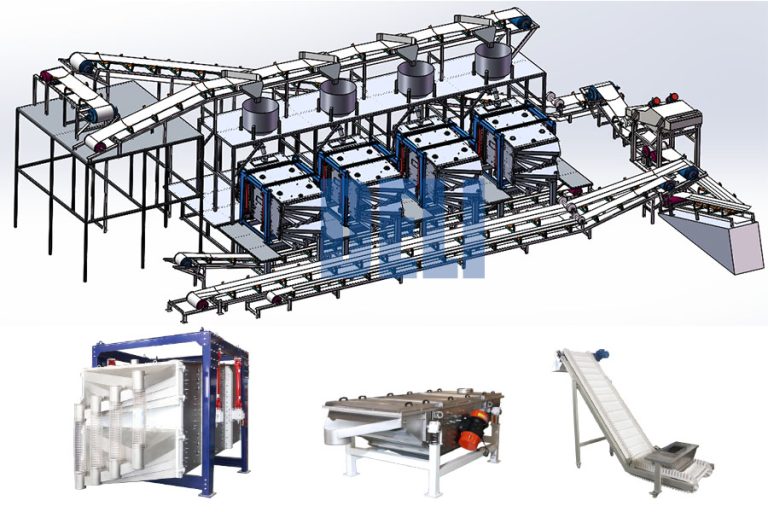

Higher efficiency and return rate

Improve equipment production capacity to increase flour factory production capacity and reduce energy consumption. This is DELI’s corporate mission. Our 48 inch vibro sieving machine can sieve more than 2 tons of flour in 1 hour, using a finer mesh of 300 microns. At the same time, DELI two deck sieving machine can directly process finished products of 300 microns to 1000 microns without secondary processing, which greatly saves customers’ time and costs.

Below is a test video of vibro sifter capacity