G2036-5P Introduction:

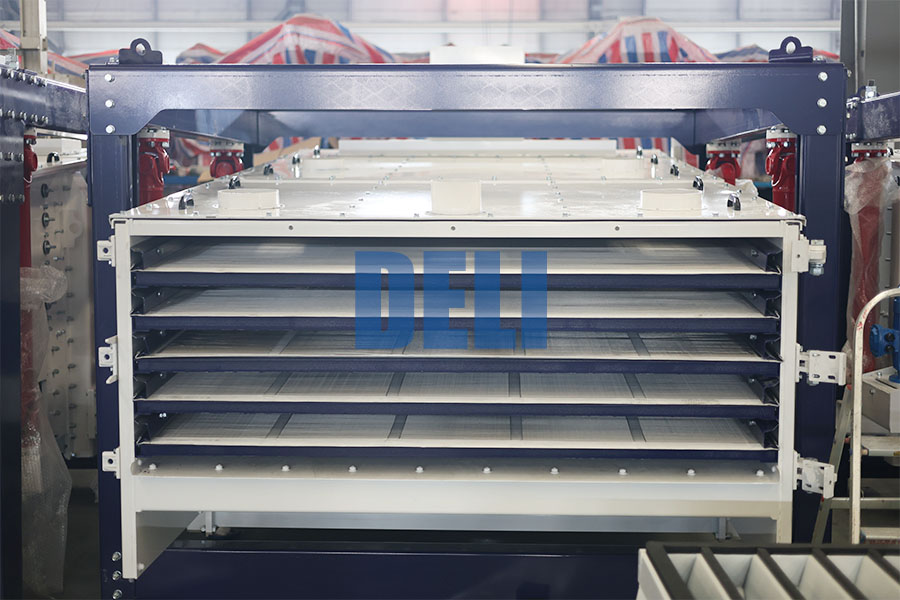

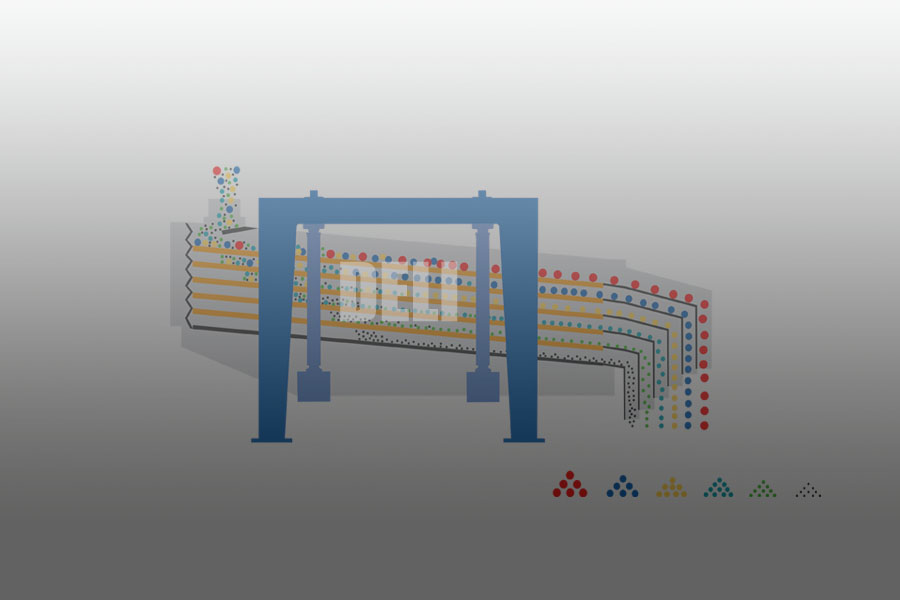

G2036-5D has 5 deck screen, screen dimension 6.56 * 11.8 feet. It consists of a screen box, a cantilever and a bracket. The motor on the screen box drives the screen box to swing left and right (imitating the movement of humans shaking the screen). Because the screen adopts a 5-degree tilt design, when the equipment is started, the material will move along the screen surface. Moves toward the discharge port along an elliptical trajectory.

This unique motion trajectory creates new value for users, more efficient screening, and higher quality products. The reasons for this result: First, the material will be spread quickly to form an ultra-thin thickness. Compared with the traditional linear screen, the thickness of the material layer is reduced, which will cause each material to participate in the screening and get more Sift thoroughly. Second, the residence time of materials on the screen surface is extended because the elliptical trajectory is used for a longer length than the linear screen trajectory, which brings a benefit that the materials are more fully screened.

Working principle:

Introduction video:

Features:

Easily access and change the screen.

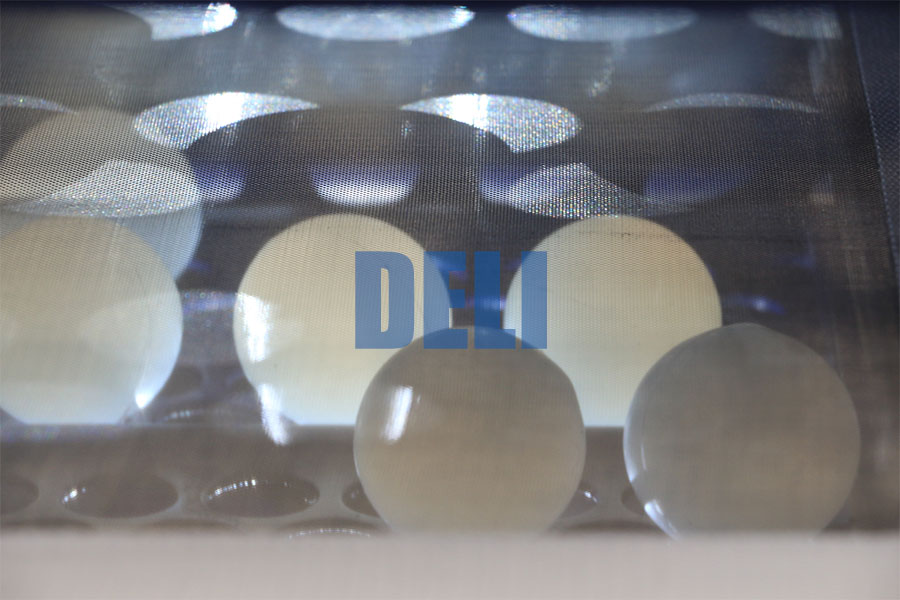

Minimum mesh size #200 / 75 micron.

Large output up to 20 tons per hour.

Screening efficiency 90%.

Specifications

| Screen layer: | 5 |

| Outelet: | 6 |

| Screen size: | 2*3.6 meter / 6.56 * 11.8 feet. |

| Mesh: | SS304 Stainless steel wire mesh |

| Mesh size: | 3~200 mesh, 0.075~6mm |

| Voltage: | 380~690v, 50/60hz, three phase |

| Bearing: | SKF |

| Power: | 7.5Kw, 1450r/min |

| Rotate speed: | 260Rpm |

| Max Inlet: | 15 tons per hour (powder or granule, bulk density 0.7, mesh size 0.5/1/2.5/5/7mm) |

Product brochure download

gyratory screener brochure

Application:

| frac sand |

| silica sand |

| quartz sand |

| Kaolin |

| Bentonite |

| Sugar |