Table of Contents

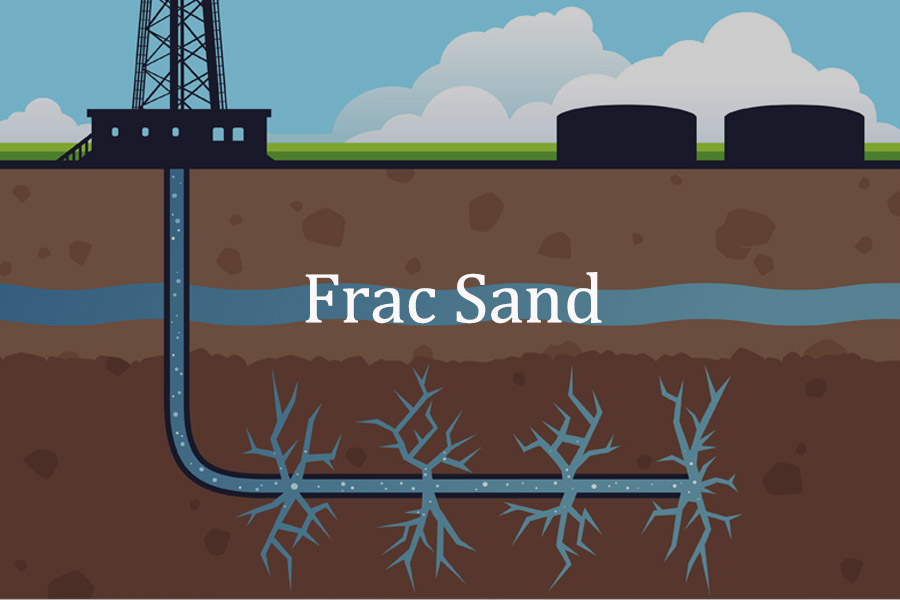

What is frac sand

Fracturing sand is a kind of quartz sand that has strong pressure resistance and roundness after fine processing. This kind of fracturing sand is often used in the petroleum industry as a petroleum proppant. Its function is to mix with liquid and then inject it underground to form cracks in the oil and gas layer. The oil and gas are collected along the cracks into the oil well and extracted.

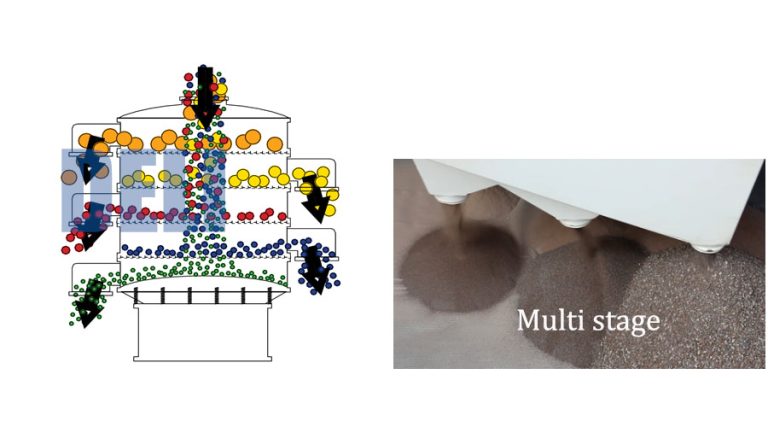

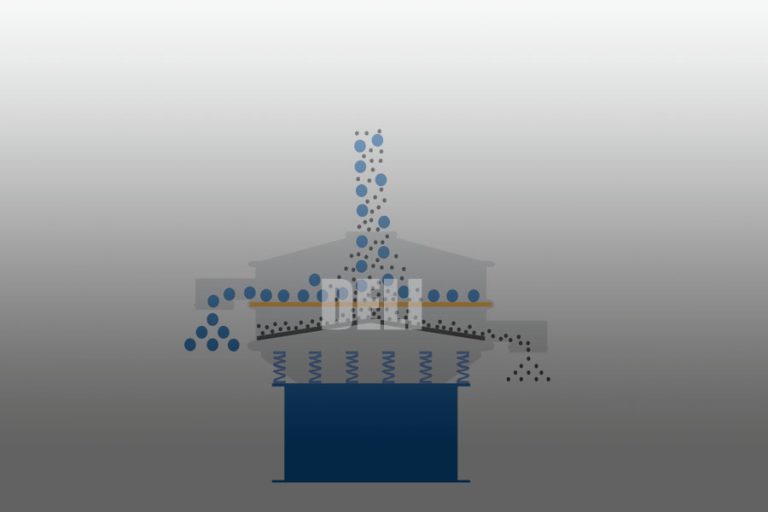

The screening machine benefits

Because the production depth of oil wells is different, the required fluidity and pressure resistance of fracturing proppant are also different. Simply, the deeper the well, the smaller the particle size of the fracking sand.

Usually the particle size of fracturing sand ranges from 20 mesh to 140 mesh (106 microns to 850 microns). Commonly used specifications are:

20~40 mesh

40~70 mesh

70~100 mesh

70~140 mesh

Fracturing sand suppliers need to produce fracturing sand with the above specifications and then supply the products to oil fields. In the production process of fracking sand, the vibrating screen is responsible for screening the raw sand into different specifications.

Key points for purchasing fracturing sand gyratory screener

- Output.

Fracturing sand is a consumable product, which requires the screening output to be high enough. The production capacity of the G series gyratory screen for screening fracturing sand can reach 20 tons per hour. If 10 pieces of equipment are deployed, the output per hour can reach 200 tons. - Because the gaps between the fracturing sand determine the efficiency of oil and gas passage and the pressure resistance of the proppant, the fracturing process has very high requirements on the dimensional accuracy of the fracturing sand. Generally, we require a screening accuracy of more than 80%, that is, the correct size of sand accounts for more than 80% of 100 tons of finished products.

- Sand has high hardness, so the mesh of the frac sand vibration screener will wear out faster. For example, the 140-mesh screen will generally begin to break after a thousand hours of operation. Therefore, fracturing sand manufacturers need to replace screens frequently, and a friendly screen changing mechanism can greatly save labor costs and downtime.