Table of Contents

The Competitiveness of Sanitary Sieving Machine

Sanitary sieving machine is an essential tool for ensuring food safety and quality. By sieving food products, these machines can remove contaminants, such as foreign objects, and ensure that the food is safe for consumption.

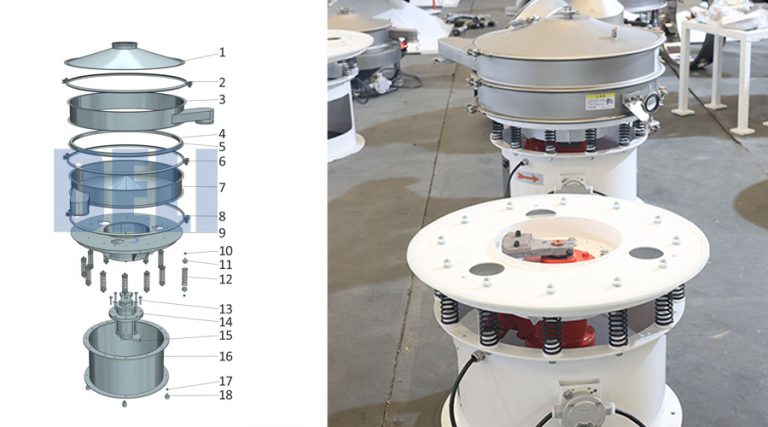

DELI industrial is a sanitary screener manufacturer, our vibro sieving machines are designed to be easy to clean and maintain, making them ideal for use in food processing facilities. The machines are constructed from stainless steel and other materials that are resistant to corrosion and bacteria. This helps to ensure that the machines remain hygienic and free from contamination.

The sieving process is also designed to be gentle on the food products, ensuring that they remain intact and of high quality. The machines are equipped with adjustable sieving screens that can be adjusted to the size of the food particles, allowing for a more precise sieving process.

The sieving process also helps to reduce the risk of food contamination. By removing contaminants, the machines help to reduce the risk of food-borne illnesses and other health risks.

In addition to improving food safety and quality, sanitary sieving machines can also help to reduce waste. By removing contaminants, the machines can help to reduce the amount of food that is wasted due to contamination. This can help to reduce costs and improve efficiency in food processing facilities.

Overall, sanitary sifter is important for ensuring food safety and quality. By removing contaminants and reducing waste, these machines can help to improve the safety and quality of food products.

Why need Sanitary Sieving Machine for Your Production Line

Investing in a sanitary gyro screener for your production line can be a great way to improve the efficiency and safety of your production process. Not only will it help you to reduce the risk of contamination, but it can also help you to increase the quality of your products. Here are some of the key benefits of investing in a sanitary vibrating screen for your production line.

1. Improved Product Quality: With the sanitary screening machine, you can ensure that your products are free from contaminants and other impurities. This will help to improve the overall quality of your products, as well as the safety of your customers.

| Model NO.: | R1200-1S |

| Material: | Outside Matte + blue powder coating |

| Surface treatment: | 304 part polish, other part blue powder coating |

| Screen layer: | 1 deck |

| Screen diameter: | 48 inch / 1200 mm |

| Net type: | Stainless steel wire mesh |

| Mesh size: | 50 ~ 5000 microns |

| Voltage: | 380v, 50hz, three phase |

| Motor brand: | OLI |

| Power: | 1.94Kw |

| Overall dimension: | 1300*1200*1150mm |

| Net weight: | 300 kg |

2. Increased Efficiency: This equipment can help to reduce the amount of time it takes to process your products. This can help to increase the efficiency of your production line, allowing you to produce more products in less time.

3. Reduced Risk of Contamination: Customer can reduce the risk of contamination in your production line. This can help to ensure that your products are safe for consumption and that they meet all safety standards.

4. Cost Savings: To reduce the cost of your production process, we provide customer affordable sieving machine. This can help to save you money in the long run, as you won’t have to spend as much on labor or materials.

Overall, investing in a sanitary sieving machine for your production line can be a great way to improve the efficiency and safety of your production process. Not only will it help to reduce the risk of contamination, but it can also help to increase the quality of your products. With all of these benefits, it’s easy to see why choosing our product is a great choice for any production line.