Table of Contents

What are the wearing parts?

As the leading powder screener factory in China, DELI industrial supply standard after sales parts for customer Globally. Regularly replacing spare parts on sieving machine is essential for ensuring optimal performance and longevity. This simple maintenance task can have a significant impact on the efficiency and effectiveness of the machine. Here are some of the key regularly replacing wearing parts on flour sieving machine:

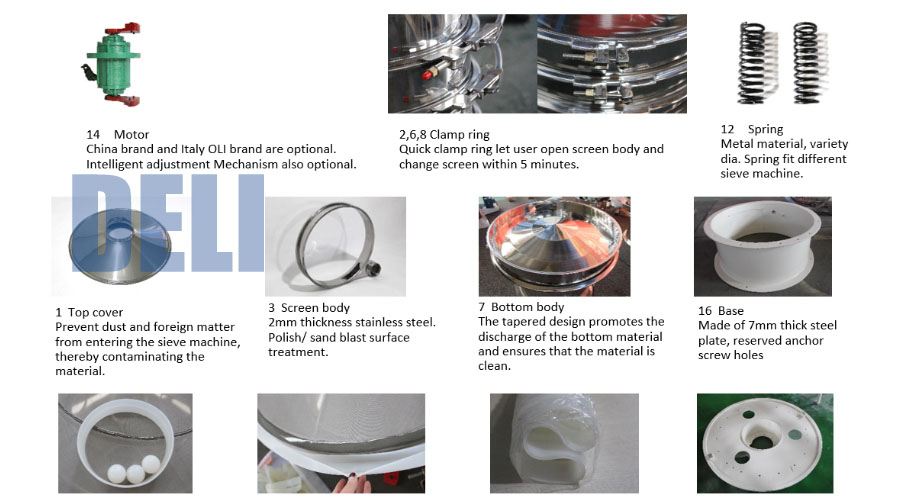

Motor: The motor is oil-free and requires no maintenance. We provide free motor return service within the one-year warranty period. We still provide motors to customers after the warranty period.

Clamp ring: SS304 stainless steel. 60 inch sieving machine and 40 inch sieving machine are different, thus pls confirm the the machine model number before order spare parts.

Vibration springs. Both Electrophoretic paint and galvanizing treatment are available.

Bouncing ball & ring: Food-grade silicone material, high resilience, the first resilience height exceeds 70%

Gasket:Sealing part on the screen. Silicone material.

When do you need to replace wearing parts?

The best performance of the spring is within 2 years after leaving the factory. Its performance will weaken after more than 2 years. You will receive a free set of springs along with the device.

Gaskets and balls wear out quickly and the minimum usage time is 3 months. If the material temperature is high, such as 80 degrees Celsius, the loss of the gasket will be significantly increased. If it is a material at room temperature, the gasket can generally be used for more than 1 year. Considering the lower price of gaskets, you may consider adding some extra gaskets to your order.

How to Identify the wearing parts before order?

You only need to provide the model and purchase time of the equipment to the factory, and we can query the matching consumables for the equipment you purchased in the system. You can find the device model number on the nameplate on the device. For example, R1500-1S represents a 60-inch vibrating screen.

Finally, it is important to regularly inspect the sieving machine for any signs of wear and tear. This will help to ensure that the machine is operating at its best and that any worn parts are replaced as soon as possible. By regularly inspecting the sieving machine and replacing any worn parts, the machine will be able to operate at its best for a longer period of time. Welcome to contact the expert of DELI industrial vibration screener factory in China.