Table of Contents

How Skimmed Milk Powder Sieving Machines Improve production Efficiency

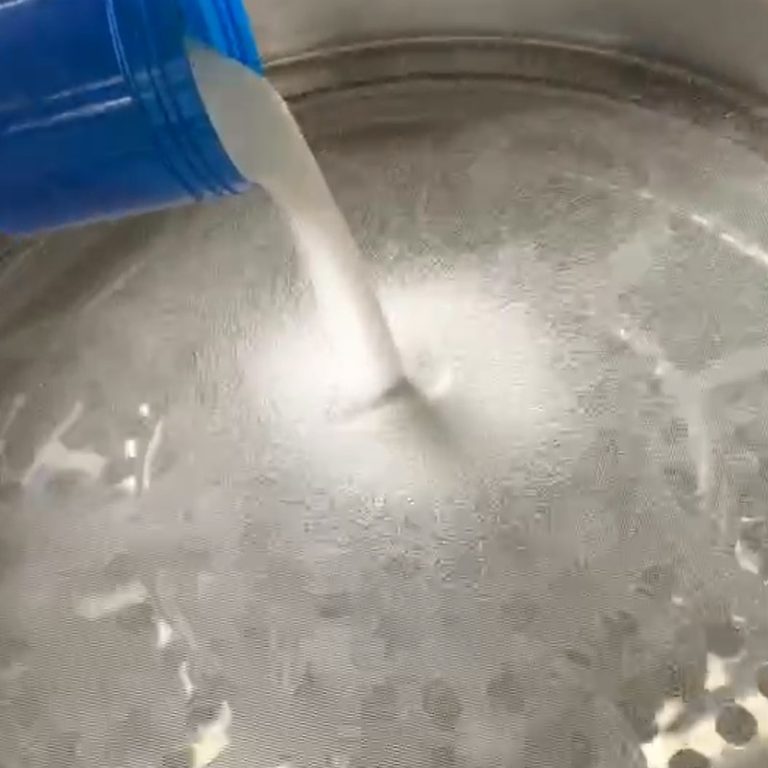

The use of skimmed milk powder sieving machines in dairy production has revolutionized the industry, allowing for greater efficiency and improved product quality. By sieving the powder, dairy producers are able to remove any impurities or foreign particles that may have been introduced during the production process. This ensures that the final product is of the highest quality and free from any contaminants.

The sieving process is relatively simple and involves passing the powder through a series of screens. The screens are designed to remove any particles that are larger than the desired size. This ensures that only the finest particles are included in the final product.

The sealing of the vibro sieving machine is very important, because milk powder will absorb moisture in the air after being exposed to the air for a long time. When the moisture content of the milk powder increases, it will become more sticky and cause agglomeration. Therefore, a sifting machine with good sealing performance is the key point to ensure the quality of milk powder.

The Benefits

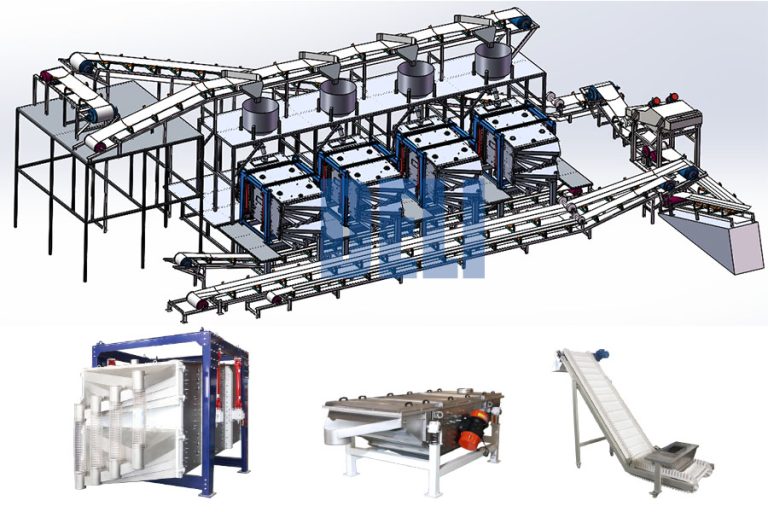

Investing in a skimmed milk powder screening machine for your dairy business can be a great way to increase efficiency and profitability. Skimmed milk powder is a valuable commodity in the dairy industry, and having the right equipment to process it can make a big difference in the quality of your product. Here are some of the benefits of investing in a WINSUN product for your dairy business.

First, our equipment can help you increase the efficiency of your production process. By sieving the powder, you can remove any impurities or foreign particles that may be present in the powder, ensuring that only the highest quality product is produced. This can help you save time and money, as you won’t have to spend time and resources on reworking or discarding batches of powder that don’t meet your standards.

Secondly, the skim milk powder screening machine can help you improve product quality. Through sealed screening, the product will maintain a good powder state and constant moisture content, resulting in a higher quality product that is more attractive to customers. This can help you increase customer satisfaction and loyalty, and increase your sales.

| Model NO.: | R1200-1S |

| Material: | Outside Matte + blue powder coating |

| Surface treatment: | 304 part polish, other part blue powder coating |

| Screen layer: | 1 deck |

| Screen diameter: | 48 inch / 1200 mm |

| Net type: | Stainless steel wire mesh |

| Mesh size: | 50 ~ 5000 microns |

| Voltage: | 380v, 50hz, three phase |

| Motor brand: | OLI |

| Power: | 1.94Kw |

| Overall dimension: | 1300*1200*1150mm |

| Net weight: | 300 kg |

Finally, a skim milk powder sieving machine can help you increase your profits. The output of the vibrating screen is 1 to 5 tons per hour. Such efficient screening can greatly improve the overall production capacity of the production line. Moreover, the vibrating screen works continuously 24 hours a day, and the motor is designed to be maintenance-free, resulting in less downtime.