Table of Contents

How Aluminum Powder Sieving Machines work

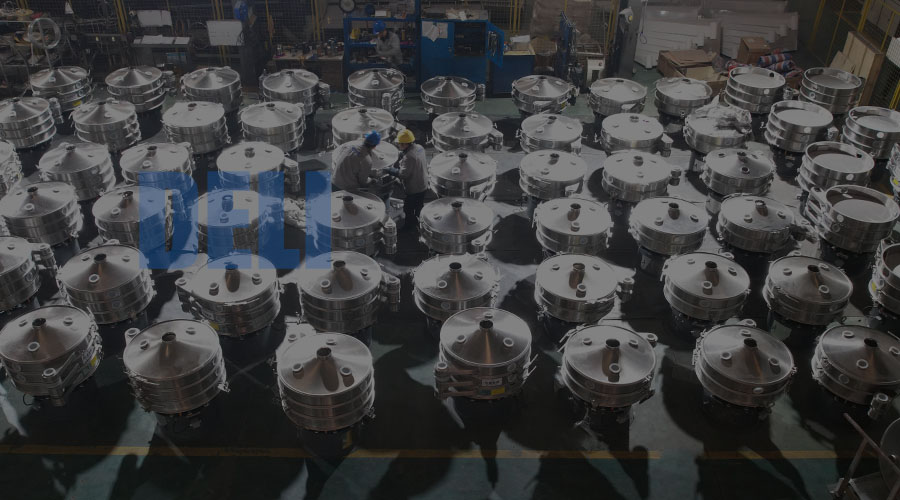

Sieving machine has some uses, one of them is Aluminum powder sieving, vibro sieving machine is an essential part of the manufacturing process, as they help to improve efficiency and reduce costs. These machines are designed to separate particles of different sizes, allowing manufacturers to produce a consistent product with minimal waste. By using sieving machines, manufacturers can ensure that the aluminum powder they produce is of the highest quality and meets all industry standards, DELI’s 48 inch sieving machine uses a 200-mesh net to sifting aluminum powder, which screening accuracy can reach more than 90%, and the output can reach 2 tons per hour. Aluminum powder with an accuracy of 90% is extremely competitive in the market.. Furthermore, sieving machines can help to reduce the amount of dust and other contaminants in the aluminum powder, resulting in a cleaner and safer product. Overall, the sifting equipment is an invaluable tool for manufacturers, as they help to improve efficiency and reduce costs.

The Benefits of this equipment

Investing in an aluminum powder sieving machine can provide numerous benefits for businesses. This type of machine is designed to quickly and accurately separate particles of different sizes, making it an ideal solution for businesses that need to process large amounts of aluminum powder. Here are some of the key benefits:

1. Increased Efficiency: It can significantly reduce the amount of time and labor required to process aluminum powder. This can help businesses save money and increase their overall efficiency.

2. Improved Quality: The sieving process can help to ensure that the aluminum powder is of the highest quality. This can help companies produce more competitive products.

3. Reduced Waste: The sieving process can help to reduce the amount of waste produced during the production process. This can help businesses to save money and reduce their environmental impact.

4. Increased Safety: An aluminum powder sieving machine can help to reduce the risk of accidents and injuries in the workplace. This can help businesses to protect their employees and ensure a safe working environment.

| Model NO.: | R1500-2S |

| Material: | Contact part SS304 stainless steel |

| Surface treatment: | Stainless steel Matte + polish, carbon steel blue powder coating |

| Screen layer: | 2 deck |

| Screen diameter: | 60 inch / 1500 mm |

| Net type: | Stainless steel wire mesh |

| Mesh size: | 100 ~ 5000 microns |

| Voltage: | 380v, 50hz, three phase |

| Motor brand: | OLI |

| Power: | 1.94Kw / 2.6Hp |

| Overall dimension: | 1600*1500*1300mm |

| Net weight: | 450 kg |

Overall, investing in an aluminum powder sieving machine can provide numerous benefits for businesses. This type of machine can help to increase efficiency, improve quality, reduce waste, and increase safety.