Five evaluation methods for best vibro sifter supplier

A High-quality vibration sifter machine supplier meet five conditions: reliable company background, professional and positive service, perfect quality control system, efficient delivery capacity, and high cost-effective products.

Combining my 14 years’ experience in vibration sifter manufacturing, I have refined five standards for evaluating qualified suppliers. It will help you avoid most procurement risks and find suitable supplier.

| NO. | Standard | Benefit |

| 1 | Verification of supplier reliability | Fund security |

| 2 | Quality of salesperson | Communication efficiency |

| 3 | Evaluation of quality control system | Equipment quality |

| 4 | Delivery capabilities evaluate | Delivery time |

| 5 | Comparative analysis of product cost performance | Price |

Before choosing a supplier, please think about the following three questions, which will help you save time.

1 Why should we evaluate suppliers?

Risk cases

Fund fraud. Supplier disappears after you pay.

Product performance does not meet the requirement. The pre-sale agreed screening processing capacity is 10 tons per hour, and the equipment you got actually reaches 5 tons per hour capacity.

Poor quality. Quality defects make the equipment unusable

No after-sales service, Unable to complain.

Benefits of high-quality suppliers

Funds are safe. The supplier will deliver the goods after receiving the payment.

Delivery is on time.

Equipment performance is guaranteed, which will be written into the contract.

The product is durable and the downtime is short.

Stable price, the price is valid for a long time.

Active pre-sales and after-sales service, save your time.

2 China suppliers Analysis

China supplier advantages

The product is cost-effective.

One advantage is worth thousands of advantages. If you can spend less money to achieve the same purpose and achieve a higher return on investment, why not. This advantage is the fundamental reason and motivation for most customers who purchase equipment from China.

Get customized services.

Firstly, the supplier is willing and able to complete your customization requirements. Second, the cost of this service is low.

There are more than 500 vibration sifter manufactures in Xinxiang, China. Their products cover a variety of requirements. Most suppliers are willing to provide customized services because they have low production costs and a comprehensive supply system.

The order production time is as short as one week.

With the automated manufacturing equipment, fast domestic logistic, and a complete supply chain locally, all the raw materials can be quickly obtained in China, and then manufactured in a shorter time.

China supplier disadvantages

No local after-sales service.

The after-sales service provided by Chinese suppliers is generally an online service. If you need on-site guidance and installation services, you need to pay extra fees.

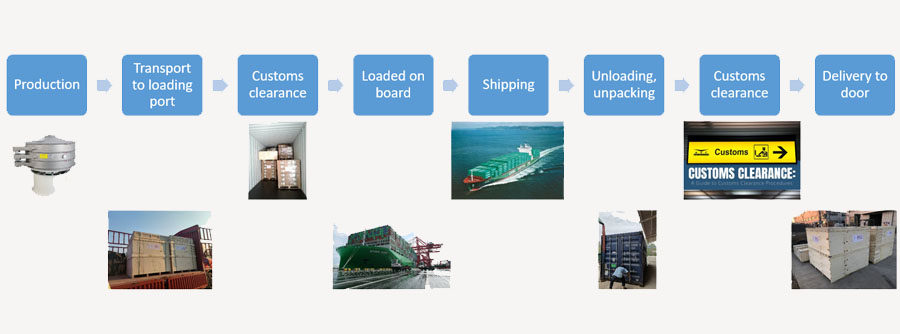

More procurement work.

Compared with purchasing vibrating sifter locally, you need to spend more time and money to handle customs clearance and tariff payment. However, this process can be completed by a local agent. The following is a flow chart of the transportation process of an equipment from China to the United States.

Agency service

The supplier’s stable supply capacity and active service are very friendly to dealers, traders and engineering companies. China supplier provide agents with agency agreements, exclusive agency agreements, customized production services, designated logo, and catalog printing.

3 vibro sifter is one of separation equipment

Classification of Separation machine

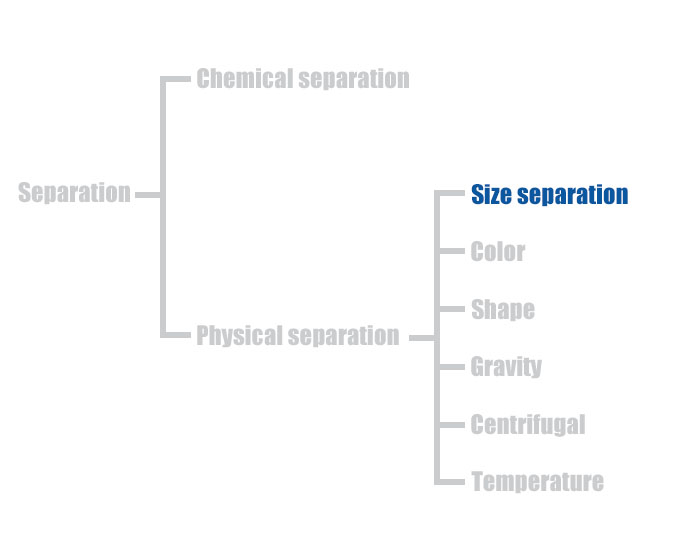

Separation equipment refers to the separation of a product into two or more products according to a certain standard.

There are two working principles of separation: chemical separation and physical separation. Chemical separation uses the principle of chemical reaction to achieve separation purpose; physical separation uses physical properties to complete separation work.

There are 6 common physical separation methods: size separation, specific gravity separation, color separation, shape separation, cold and hot separation, centrifugal separation. Among them, size separation technology has two application forms: vibrating screen and filter paper separator.

The following figure shows the position of the vibrating screen in the separation equipment.

Classification of size sepration equipment

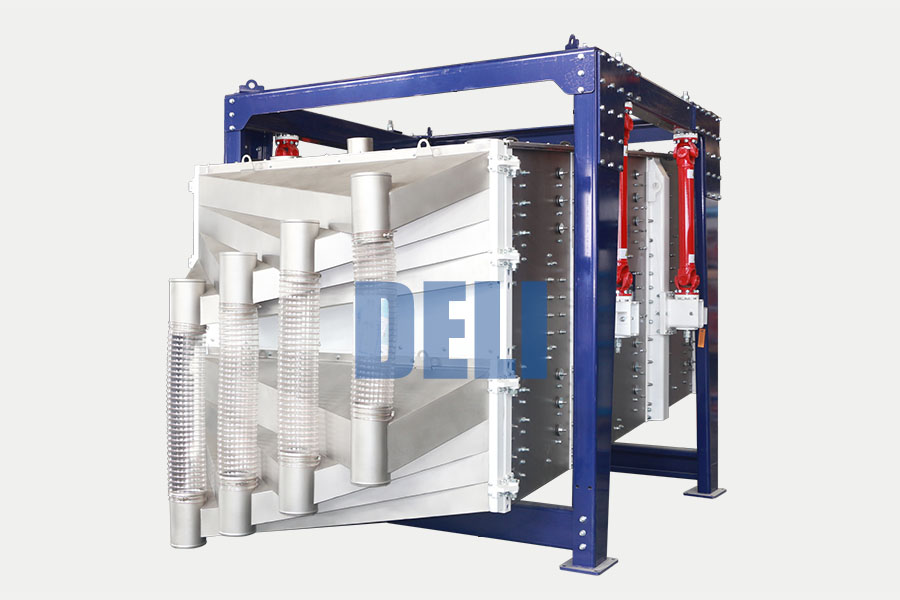

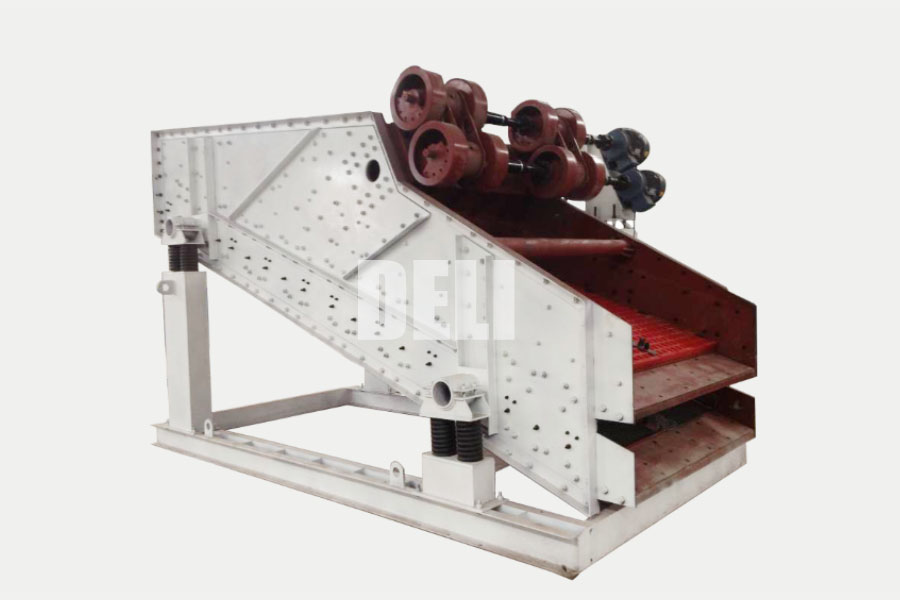

The original vibratory screener was used for coal screening. It had only one structure. Later, as the scope of application of the vibratory screener expanded, humans designed different versions to meet the application needs of different industries. There are 8 types of vibrating screens with a wide range of applications:

Circular vibro sifter, Tumbler screening machine, linear vibrating screen, large capacity vibration screener, Gyratory screener, flat rotary screen, circular vibration screen, dewatering screen, trommel screen.

Characteristics.

The minimum particle size can reach 325 mesh (45 microns).

Simple structure and durable.

The output can reach up to 100 tons/hour.

Wide range of applications, powder, particles, solid-liquid mixtures can be screened.

4 Vibro sifter introduction

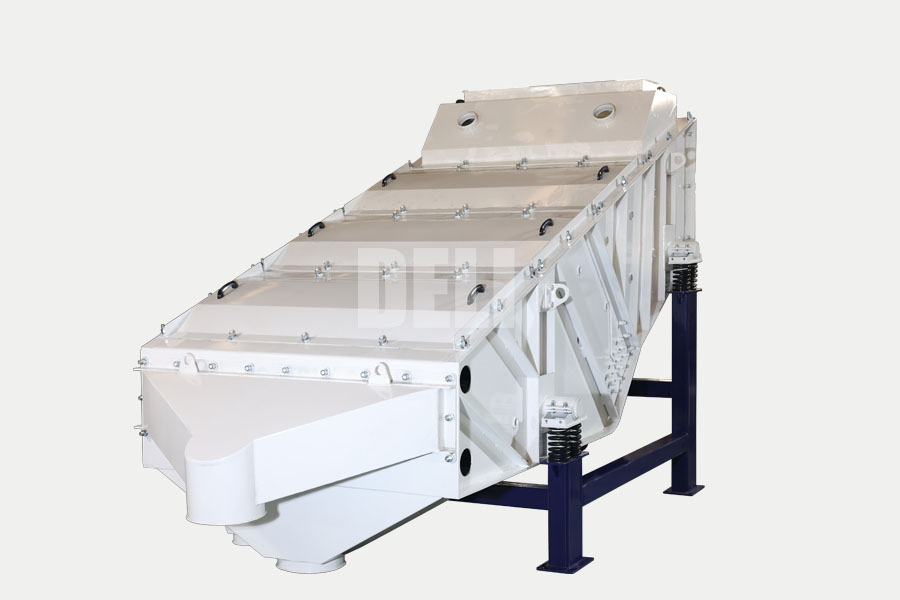

It has the characteristics of small overall size, wide application and easy maintenance. Its only disadvantage is low production capacity. When screening ordinary powder with 1mm mesh, its output is 5 tons per hour, which is mainly because its maximum diameter of the screen area is only 1.5 meters.

Working principle

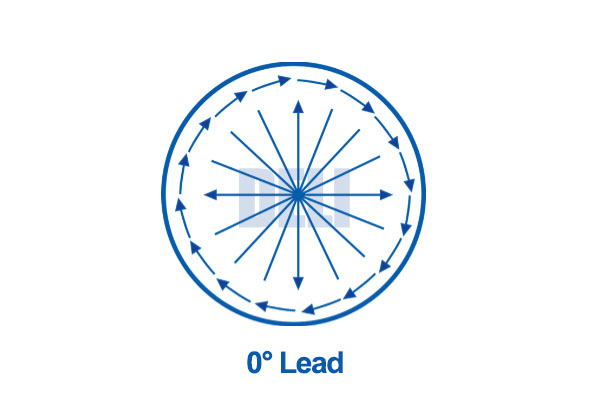

The industrial sifter machine is driven by a vertical asynchronous vibrating motor. Under the unique vibration mode, the material pass through the mesh and be quickly separated into products of different particle sizes.

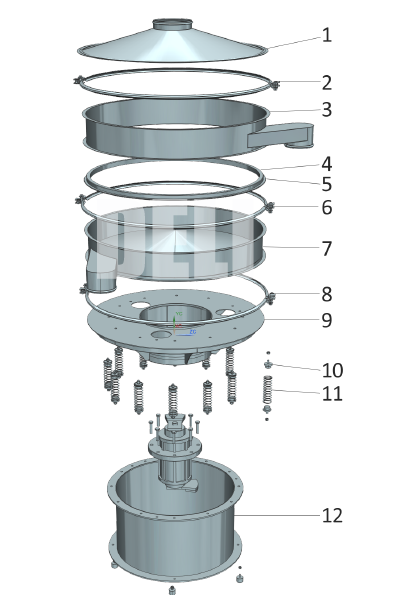

structure

It consists of cover, spacer, screen, seal, clamp ring, table spacer, base flange, spring, motor and Base.

Functions

Quick access

users can complete screen maintenance and replacement in just 10 minutes, and this process does not require any tools.

Multi-layer deck combination

Vibro sifter can use 4 layers of screens at the same time to complete 5 stages of screening. Users can increase or decrease the number of decks by themselves.

Adjustable vibration force

The advanced force wheel drive design allows users to adjust the amplitude of the sieve machine, and then adjust the screening speed and output size to fully adapt to your materials.

5 Classification of Vibro sifter

DELI’s vibro sifter machine has 4 series: Stainless steel vibro sifter, ultrasonic vibro sifter, side discharge vibratory separator, high frequency vibration sifter for liquid.

The difference

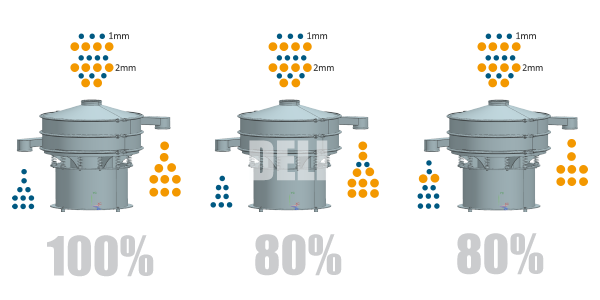

DELI’s three vibro sieve can identify products with a particle size range of 48 microns to 10 mm, with a screening capacity of up to 10 tons per hour. These three products are suitable for different production and particle size requirements. The figure below shows their respective optimal working areas.

| Series | Particle size MM | Capcity Tons per hour |

| RS Side outlet version | 0.3~10 | 0.1~10 |

| R Normal version | 0.075~4 | 0.1~5 |

| RU Ultrasonic version | 0.038~0.3 | 0.1~3 |

6 How to quickly find suppliers online

I recommend online channels to find suppliers, because there are few offline exhibitions for vibro separator, and most Chinese suppliers will not attend overseas exhibitions, because the cost of offline exhibitions is high, and the value of sifter equipment is relatively low. For vibro separator manufacturers, the return on investment of the exhibition is low.

Online channels include Google search engine, Youtube, Alibaba, made in China, Facebook, Tiktok, etc.

It is recommended to use the Google and Youtube. The results provided by Google are the most comprehensive, and Youtube allows you to visit fresh videos of manufacturers and their products, which will help you quickly distinguish and find the right one.

Distributors are not recommended to use B2B platforms, because the suppliers on B2B platforms are open to all customers, including the downstream customers of distributors, which conflicts with the distributor’s agency sales model.

Now you may have found about 10 suppliers, all of them provide similar products. How to find the best one among them? Let’s start with the Five evaluation methods for best supplier.

7 verification of supplier reliability

The supplier’s company really exists

This will protect your funds and ensure that you are dealing with a legitimate Chinese company. Chinese companies must register with the government system and obtain a business license before they manufacture and sale machines, which means you can ask the salespeople for a business license.

You can check the ID on the business license in the Chinese government, the query portal is https://www.gsxt.gov.cn/index.html

Note, you can only input Chinese characters on that website, but you can just input the license ID to check the company reliability and use the google translate when you want to read the company information.

Have production and export qualifications

Chinese companies must obtain export qualifications to sell goods to foreign customers, otherwise Chinese customs will not allow the goods to leave China. A classic case is that customer A and facotry B reached an order after a long negotiation. When paying the payment, customer A learned that factory B did not have export qualifications, which meant that the factory could not legally collect overseas US dollars and could not ship the goods out of China. The result is that A must pay the funds to the factory through a third-party trading company, which increases the risk of funds and wastes a lot of time. So, please confirm whether the they have export qualifications at the beginning.

The factory really exists

Factory or trading company, this is an old question. If you can’t visit the factory, I suggest not to spend too much time on this matter, because the five evaluation methond can answer this question.

A simple and effective way we recommend is to have a video conference with the supplier’s salesperson, during which you can visit the factory online.

8 Quality of salesperson

Salespeople are the only bridge for you to communicate with the supplier. Whether suppliers can fully and accurately understand your needs depends entirely on the ability and attitude of salespeople, so salespeople should have the following five business qualities:

9 Evaluation of quality control system

DELI delivers durable products

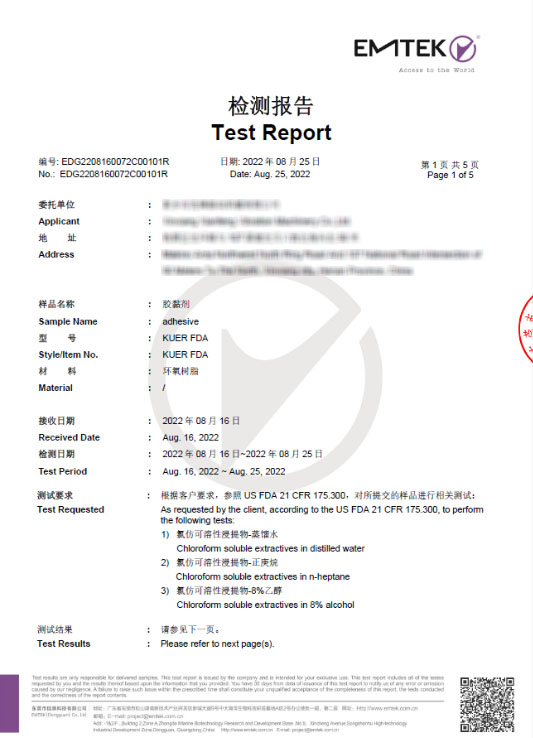

The quality control system is the most important reliance for suppliers to provide you the stable and reliable products. So we need to spend enough time to do the evaluation, which determines whether the quality of the products you receive is qualified and durable. However, a good salesperson will speed up this process and save your time.

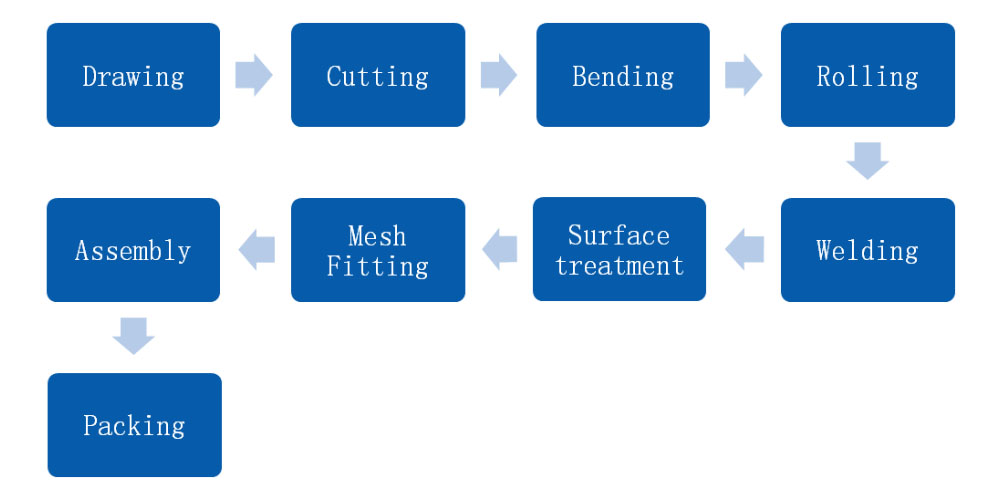

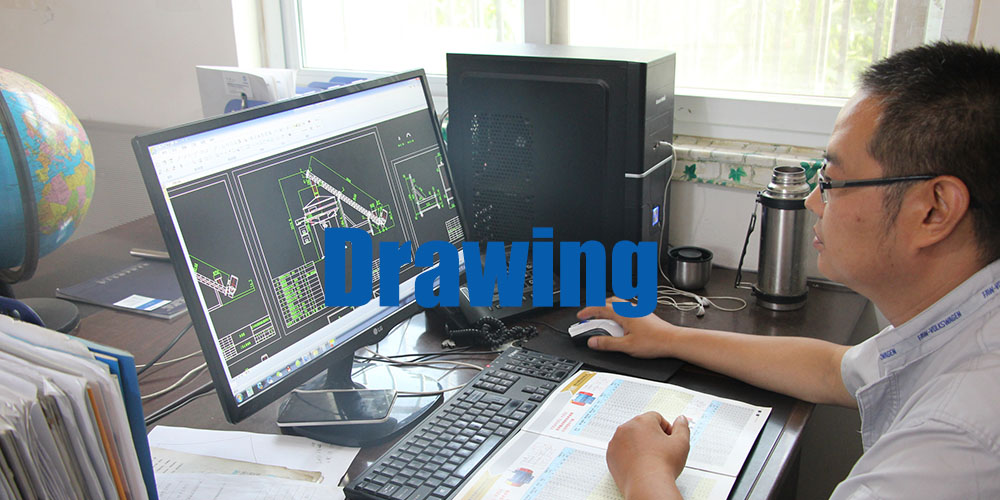

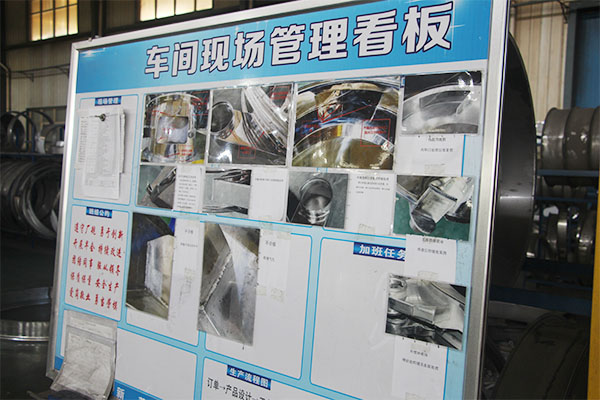

Manufacturing process

The manufacturing of vibrating sieve is divided into 10 processes: design, cutting, bending, rolling, welding, surface treating, screen manufacturing, assembly, and packaging. We all want to get excellent quality equipment, quality is the result, and the reason is the production process and quality control process of the equipment. The following picture will help you quickly become a vibration sifter expert.

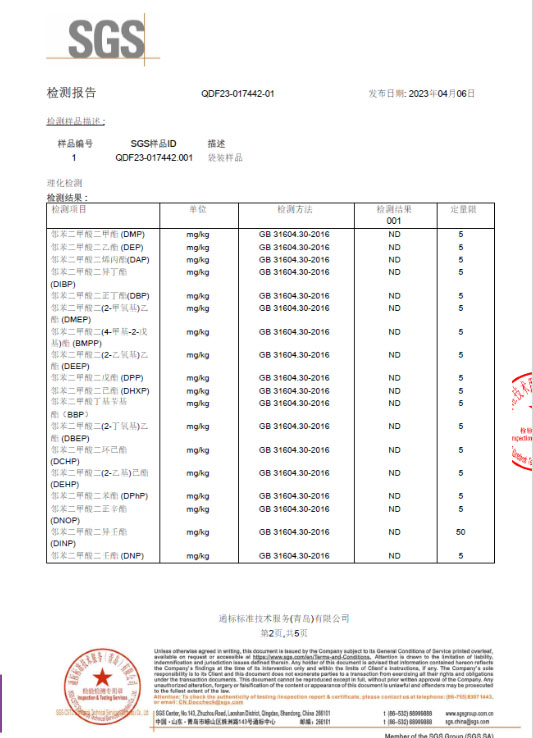

The quality control system consists of three parts: incoming material inspection, production process quality control and pre-delivery inspection.

Quality Control Cases

Welding quality

Since the machine is small in size, most of the parts are connected by welding, so the welding quality determines the structural strength of the small circular sifter.

Welding porosity is fatal to the strength after welding, which is the most basic and important inspection item in the quality control process.

Full welding in the important position

Spot welding, segment welding and full welding are common welding types. Use the correct welding method in the correct position.

The bottom spacer bears all the vibration force of the upper part of the screen.

Surface treatment

Surface treatment includes stainless steel treatment, weld treatment, carbon steel painting, parts galvanizing, etc. Stainless steel has a brighter luster and its flaws become more obvious. Qualified surface treatment should be uniform and without dead angles.

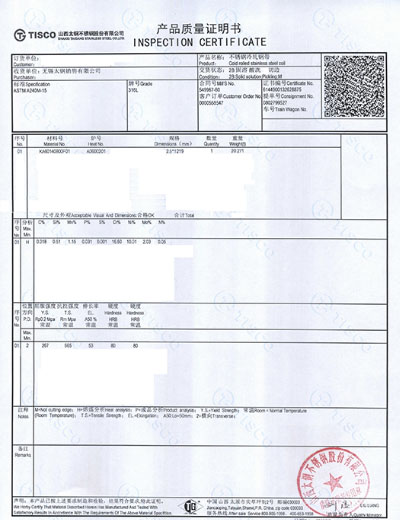

How to determine the raw materials quality?

You can ask the factory for a raw material certificate. An important detail is that the stainless steel plate certificate contains the material composition of stainless steel, which can help you judge the quality of stainless steel.

Production process quality control

Material flow card, size measurement during manufacturing, polishing effect inspection, and welding qualification inspection are necessary. You can ask the salespeople whether there are these systems and means, and ask for some photos to prove that they implements these systems during the production process.

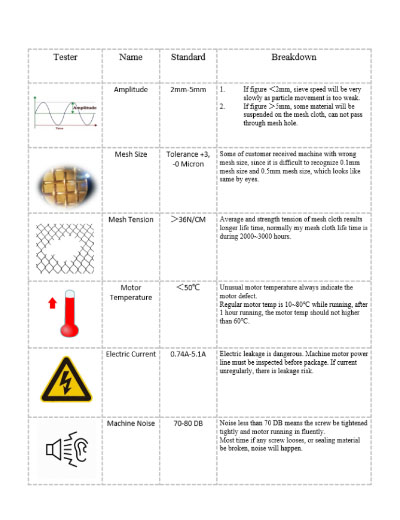

Inspection before delivery

The figure below shows the seven inspection standards of DELI. Every machine delivered by DELI must meet these 7 inspection standards:

1. Mesh size tolerance.

2. Vibration amplitude.

3. Wire mesh tension.

4. Motor temperature.

5. Machine operation noise.

6. Rated current.

7. Machine dimension.

10 Delivery capabilities evaluate

Delivery capability includes on-time delivery, correct delivery, safe packaging and affordable freight.

On-time delivery

This is the most difficult evaluate term because there are some uncertainties in the shipping, such as shipping company warehouse explosion, holidays, etc.

But its importance makes us have to try to ensure faster delivery. Especially for new projects, the lack of any equipment will cause the entire production line to be unable to start on time, causing huge economic losses.

What we can do before placing an order is to choose a professional manufacturer and a great salesperson, and determine whether the delivery progress meets expectations by regularly obtaining production progress. Please refer to the production process above, you can timely understand which manufacturing stage your order is in.

Safe Packaging

The qualified thickness and reasonable structure of the packaging box protect the vibration sieve from damage during transportation. In addition, each equipment should purchase transportation insurance.

Another situation is full container shipping. The supplier should take necessary reinforcement work to ensure that the stacked packaging will not fall or collide during transportation. The following is a photo of the reinforcement of the vibration screen in the container, which is fixed with wood blocks and reinforced with steel wire ropes. Container reinforcement picture.

Add a special case. If you need to transport the sieve machine by air, try to use thinner materials for the wooden box. Lightweight packaging can save considerable air freight.

Affordable freight

When the above two conditions are met, the transportation of equipment should pursue lower freight.

1. Reasonable packaging size.

Reasonable packaging has a small volume and lower sea freight.

2. Professional labels and shipping mark.

The information on the nameplate and shipping amrk of the equipment should be correct. Wrong label information will result in fines. Some countries have strict label review on imported goods. For example, customs in Indonesia, Saudi Arabia, the United States will strictly check whether the shipping mark information on the vibration sifter packaging is consistent with the bill of lading information.

3. Correct use of HS code.

HS code is an important basis for customs to levy tariffs. We try to choose codes with lower tariff rates as much as possible, but the premise is that this code is available for vibro sifter. As of October 29, 2024, the United States will impose a 20% tariff on vibrating screen goods with HS CODE 847410, but some HS codes are exempt from tariffs. Reasonable use of HS codes can reduce customers’ tax costs.

4. Declare preferential trade policies.

China has signed trade reciprocity treaties with many countries, which reduce or exempt import tariffs on products from China. To get the tariff reductions, you need to submit some documents to the customs, which are supplied from the supplier.

Correct delivery

The specifications and quantity of the goods are correct. This seemingly simple issue but it can have disastrous consequences. For example, If the mesh size does not meet the requirements, supplier ship the wrong mesh size screen to you, the sieving equipment will not be able to work. This once again highlights the importance of the quality control system.

In addition, you have the right to obtain detailed photos of the goods and inspection reports from the supplier before paying the balance, and check again that the goods meet your requirements.

11 Comparative analysis of product cost performance

The best product is a product with good quality and low price. Standards one, two, three, and four are used to evaluate whether the factory can provide “good quality” products, and the NO. Five standard involves “low price” issue, so I put this criterion at the end.

Cost-effectiveness refers to a good balance between high quality and price. The higher the quality, the higher the price. In most cases, I am unwilling to spend the highest price to buy the most perfect equipment. I would rather spend 50% of the price of a perfect product to buy a vibrating sieve with 80% of the performance of a perfect product. We will evaluate the cost-effectiveness of the product through the following three dimensions: quotation plan, product performance, and warranty policy.

Quotation plan

What should the quotation plan include?

Price with delivery terms.

Drawings and technical parameters.

Photos or videos of the equipment.

Performance indicators.

Accessories price and loss cycle.

How to compare quotations

1. The supplier provides all the above information. The complete quotation information describes the “product” from different aspects, and the description will be part of the contract and become a complete contract. The lack of any document cannot unify the understanding of “product” between customers and suppliers, which is the reason why customers think that the product is unqualified without clear evidence.

2. The supplier meets standards one, two, three, and four.

3. After meeting the above two conditions, choose the one with a lower price; if the price is close, and please evaluate the suppliers one by one according to standards one, two, three, and four.

Product performance

The product performance of the vibratory sifter refers to the output and separation accuracy.

The output represents how many products the equipment can process per hour, and the unit of output is tons/hour or cubic meters/hour.

Separation accuracy = (oversized material weight + undersized material weight) / total weight of the finished product. A simple understanding of separation accuracy is the proportion of products with the correct particle size in the finished product. Assuming that the vibratory sieve outputs products A B C, The total weight of B is 100kg, there is 10kg C in the B, the separate accuracy of B will be 90%.

Warranty policy

As mentioned at the beginning, one of the shortcomings of Chinese manufacturers is that they do not have local after-sales service capabilities, so the warranty policy is a necessary factor for customers to evaluate the value of the product.

The warranty policy consists of three issues: warranty period, warranty scope, quality failure judgment standard, factory responsibility scope, and after-sales channel.

Warranty period, generally one year, DELI calculates the warranty time from the date the customer receives the equipment.

Warranty scope, whole machine, except for the wire mesh screen.

Quality failure judgment standard, DELI only requires customers to provide fault photos to quickly solve after-sales issue for customers.

Supplier responsibility scope, some suppliers only stand the material costs involved in maintenance, and customers need to pay the freight of accessories, and DELI stand all costs (the freight is sea freight, and air freight requires additional money).

After-sales channel. Except for personnel dispatch, everything is free.

Contact our experts to obtain DELI’s warranty.

The above are five evaluation methods for best vibro sifter supplier. I hope it can help you find the satisfied supplier and cost-effective vibration sifter machine.

I will continue to review customer cases and update this article from time to time.

The video version will be released soon. Welcome to subscribe to our youtube channel.