Table of Contents

How to adjust the amplitude on vibrating screen

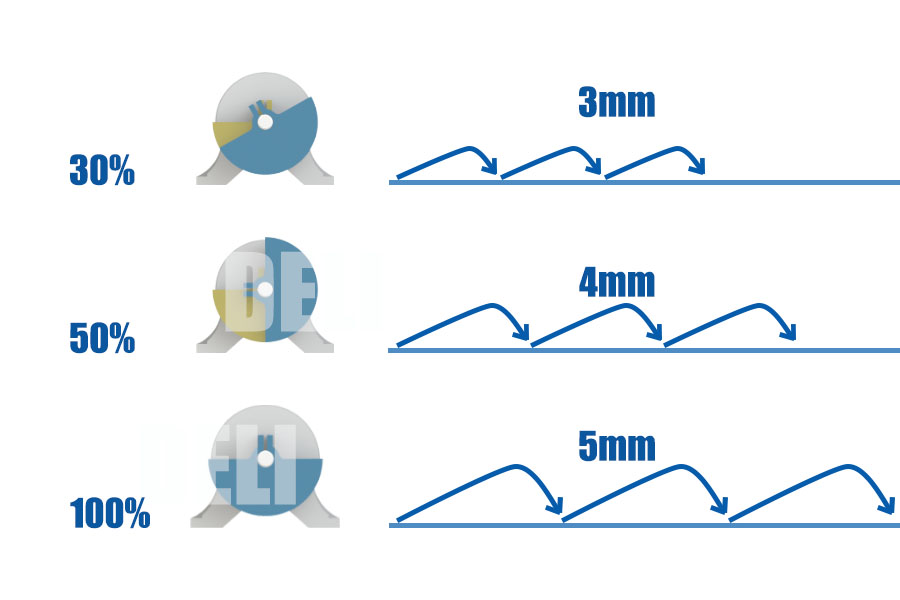

Adjusting the amplitude involves three key points: exciting force, amplitude, and material travel. They are positively correlated. The higher the exciting force, the larger the amplitude, and the longer the material travel.

DELI linear vibrating screener amplitude range is 3~5mm.

Below we begin to explain how to improve the screening effect by adjusting the amplitude.

Below are the adjustment steps and operation video.

- Disconnect the power supply

- Open the cover of the horizontal vibration motor

- Use a wrench to release the counterweight fixing screws

- Rotate the counterweight to the required angle

- Make sure that the angle of each counterweight is the same

- Tighten the counterweight screws

- Install the vibration motor cover

- Turn on the power supply and measure the amplitude of the vibrating screen

What is the vibrating amplitude

Exciting force and stroke

Amplitude refers to the amplitude of movement of the vibrating screen surface. The amplitude range of the fine powder linear vibrating screen is 3~5mm. The larger the amplitude, the greater the screening output.

The working principle of the vibrating screen is that the horizontal vibrating motor drives the screen to move vertically and radially. The intuitive performance is that the screen moves up and down in one direction. The distance between the highest point and the lowest point of the screen movement is the amplitude.

| Weight block angle | Amplitude |

| 30% | Minimum 3mm |

| 100% | Maxmum 5mm |

Why need adjust the amplitude?

First of all, the role of vibration is to accelerate the material through the screen and make the material move toward the discharge port. Therefore, the amplitude value affects the output and screening effect of the screen machine.

It is not the bigger the better. For products with low bulk density, such as activated carbon, higher amplitude will cause the material to be thrown too high, which will slow down the speed of the material passing through the mesh, and then cause the problem of incomplete material screening. Therefore, the amplitude should be adjusted according to different material characteristics. The following table shows the recommended amplitudes for some materials.

| Application | Exciting force | Amplitude |

| Light powder | 30% | 3mm |

| Heavy particles | 100% | 5mm |

| Activated carbon | 50% | 3.5mm |

| Wet wood chips | 100% | 5mm |

Related product