Table of Contents

Why use the Stainless Steel Flour Circular Screens

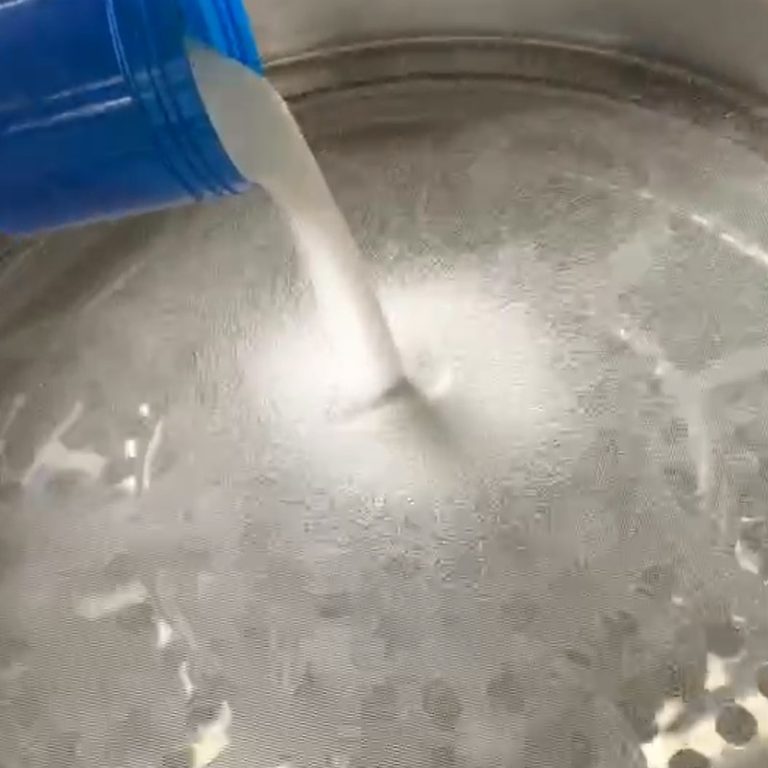

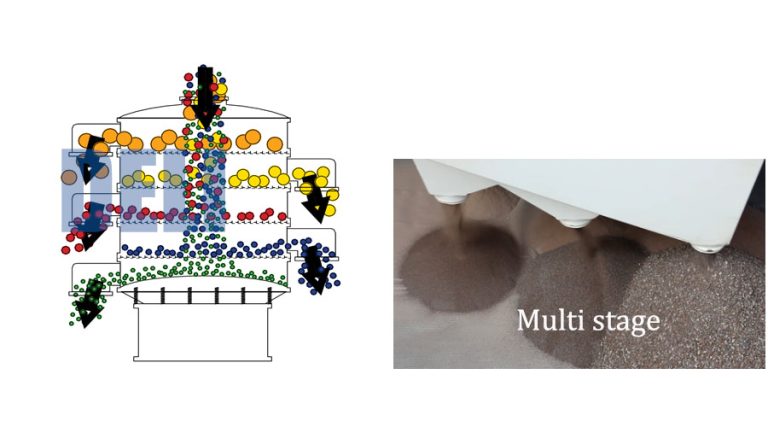

Stainless steel flour sieving machines are an essential tool in food processing. They are used to separate and sift flour, as well as other food products, to ensure that the final product is of the highest quality. The use of stainless steel sieving machine offers a number of benefits to food processors.

First, the vibrating screen are highly durable and resistant to corrosion. This makes them ideal for use in food processing, as they can withstand the harsh conditions of the environment. Additionally, stainless steel is non-porous, meaning that it does not absorb any of the food particles that it is sifting. This ensures that the final product is free of contaminants and is of the highest quality.

Second, sifting equipment is easy to clean and maintain. This is important in food processing, as it helps to ensure that the final product is free of bacteria and other contaminants. Additionally, stainless steel is non-reactive, meaning that it does not react with any of the food particles that it is sifting. This helps to ensure that the final product is safe for consumption.

| Model NO.: | R800-1S |

| Material: | Contact part SS304 stainless steel |

| Surface treatment: | 304 part polish, other part blue powder coating |

| Screen layer: | 1 deck |

| Screen diameter: | 30 inch / 800 mm |

| Net type: | Stainless steel wire mesh |

| Mesh size: | 100 ~ 5000 microns |

| Voltage: | 380v, 50hz, three phase |

| Motor brand: | OLI |

| Power: | 0.4Kw |

| Overall dimension: | 900*800*930mm |

| Net weight: | 136 kg |

Finally, flour sieving machine is cost-effective. They are relatively inexpensive to purchase and maintain, making them an ideal choice for food processors. Additionally, they are easy to install and use, meaning that they can be used in a variety of food processing applications.

Overall, stainless steel flour screeners are an essential tool in food processing. They are highly durable and resistant to corrosion, easy to clean and maintain, and cost-effective. These benefits make them an ideal choice for food processors looking to ensure that their final product is of the highest quality.

How to maintain the Flour sieving machine

Stainless steel flour vibro sifters are an essential part of the milling process, as the flour formed after grinding wheat contains some large particles of impurities. To ensure optimal performance, it is important to properly clean and maintain these screens. Here are some tips for doing so:

1. Clean the screens regularly. It is important to clean the screens after each use to remove any flour or other debris that may have accumulated. Stop feeding and let the sieving machine run without load for 5 to 10 minutes. The jumping ball will remove the impurities in the mesh and the screen machine will discharge the materials to ensure that there are not too many remaining materials in the screen machine. These flour may be retained for a period of time. Absorbs moisture in the air and then adsorbs on the screen net and spacer part.

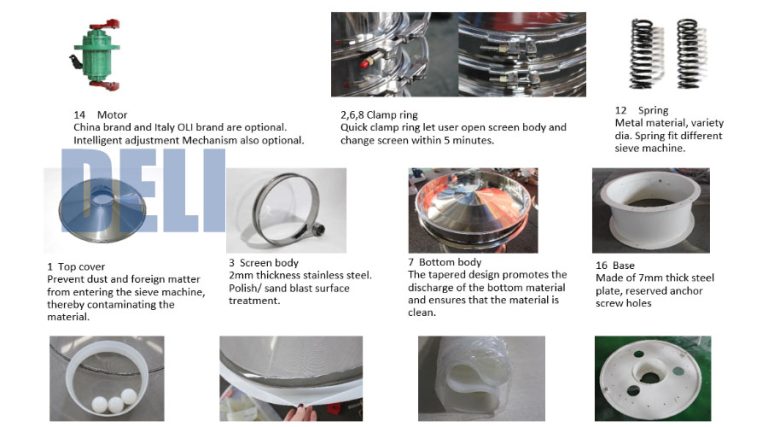

2. Inspect the screens for any signs of wear or damage. If any damage is found, it should be repaired or replaced immediately.

3. Check the spring performance. Once the spring elasticity is found to have decreased, replace it with a new spring in time.

4. Store the screens properly. When not in use, the screens should be stored in a dry, cool place. This will help to prevent rust and corrosion.

5. Check the equipment for any abnormal noise. Abnormal noise may be caused by a loose harness ring or motor failure.

By following these tips, you can ensure that your stainless steel flour circular screens are properly cleaned and maintained for optimal performance.