Table of Contents

The Benefits of Using Stainless Steel vibro sieving Machine

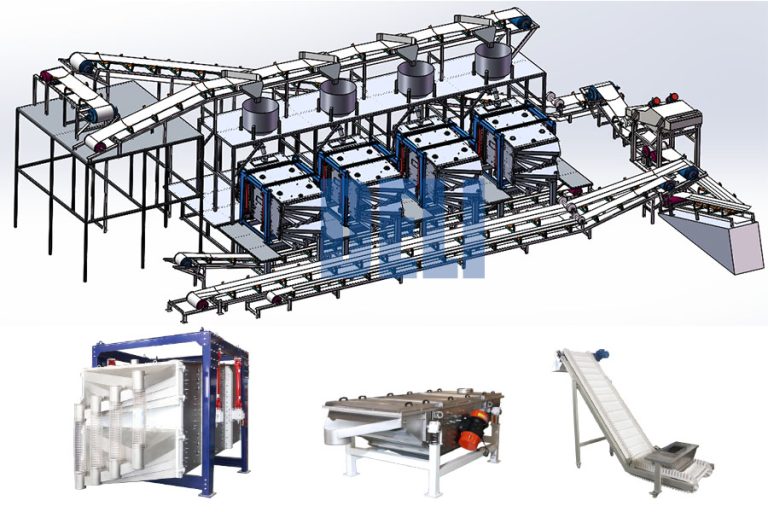

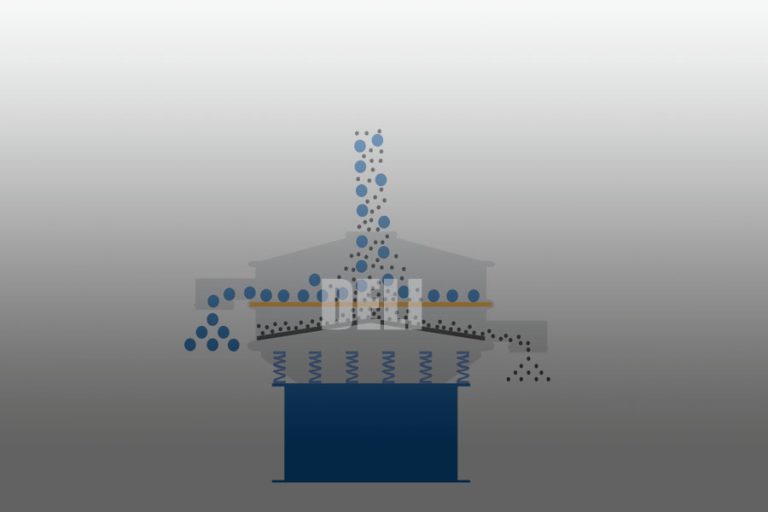

Stainless steel sieving machine offers some benefits when compared to other materials. Stainless steel is a durable and corrosion-resistant material, making it ideal for use in industrial settings. It is also non-magnetic, meaning it won’t be affected by magnetic fields, and it is non-porous, meaning it won’t absorb liquids or other materials. This makes it an ideal choice for sieving machines, as it won’t be affected by the materials being sieved.

Stainless steel sieving machines are also easy to clean and maintain. The material is resistant to rust and corrosion, so it won’t need to be replaced as often as other materials. This makes it a cost-effective choice for industrial applications. Additionally, stainless steel is a hygienic material, making it ideal for use in food processing and other industries where hygiene is a priority.

Finally, stainless steel is more durable compare with carbon steel and can withstand heavy use. This makes them ideal for use in industrial settings, where they may be used for long periods of time. The material is also resistant to wear and tear, meaning it won’t need to be replaced as often as other materials. This makes it a cost-effective choice for industrial applications.

Overall, using a stainless steel screener for industrial applications offers a number of benefits. Vibro sifter supplier is important during customer purchasing, you shall ensure that the equipment material is durable, corrosion-resistant, non-magnetic, non-porous, easy to clean and maintain, and highly durable. This makes it an ideal choice for industrial applications, where it can provide a cost-effective and hygienic solution.

How to Maintain Stainless Steel Vibro sieving Machine

Maintaining and caring for your stainless steel vibrating screen is essential for optimal performance. Here are some tips to help you keep your machine in top condition:

1. Clean the machine regularly. Make sure to use a soft cloth and mild detergent to remove any dirt or debris that may have accumulated in the machine.

2. Inspect the machine for any signs of wear or damage. If you notice any issues, contact a professional for repairs.

3. Lubricate the machine regularly. This will help keep the moving parts of the machine running smoothly and reduce the risk of breakdowns.

4. Check the sieve screens for any signs of damage or wear. If you notice any issues, replace the screens as soon as possible.

5. Make sure to store the machine in a dry, dust-free environment. This will help keep the machine in good condition and reduce the risk of rust or corrosion.

By following these tips, you can ensure that your stainless steel sieving machine is well maintained and performs optimally.

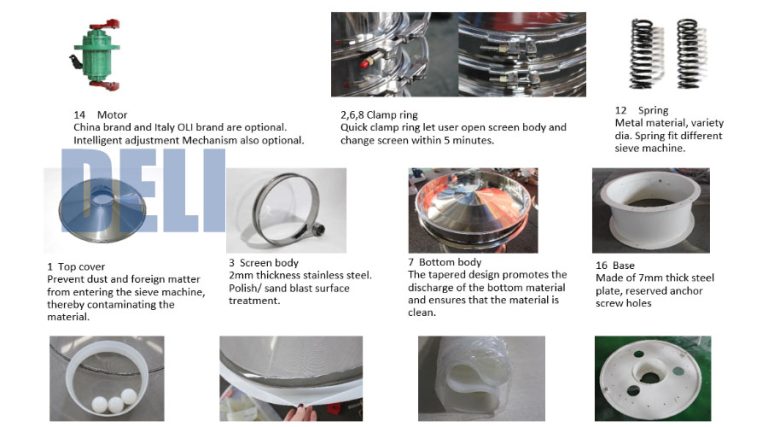

Machine speficications:

| Model NO.: | R1500-2S |

| Material: | Contact part SS304 stainless steel |

| Surface treatment: | Stainless steel Matte + polish, carbon steel blue powder coating |

| Screen layer: | 2 deck |

| Screen diameter: | 60 inch / 1500 mm |

| Net type: | Stainless steel wire mesh |

| Mesh size: | 100 ~ 5000 microns |

| Voltage: | 380v, 50hz, three phase |

| Motor brand: | OLI |

| Power: | 1.94Kw / 2.6Hp |

| Overall dimension: | 1600*1500*1300mm |

| Net weight: | 450 kg |

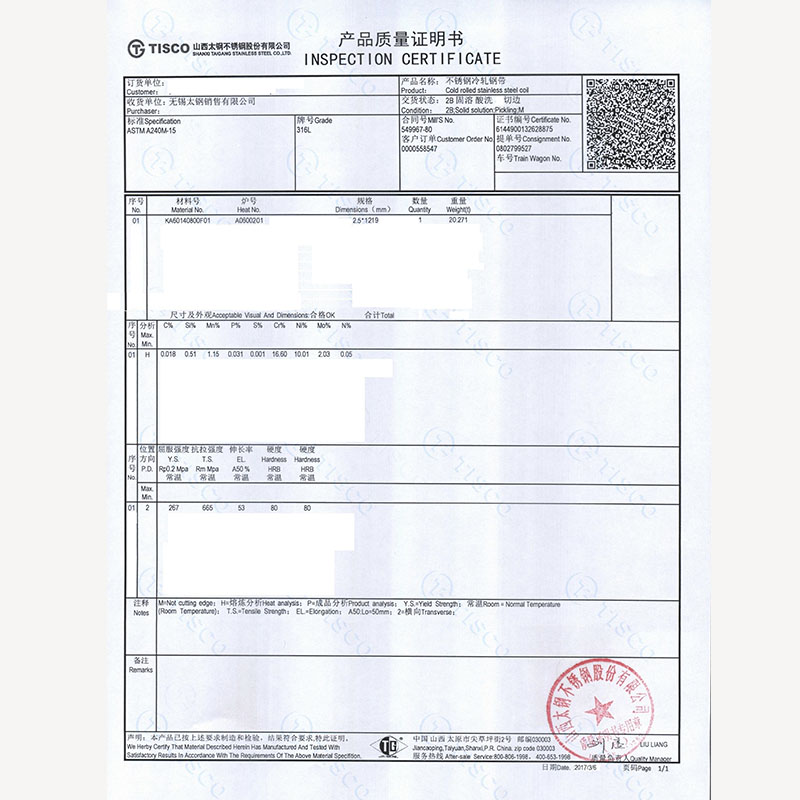

Stainless steel material certificate