Table of Contents

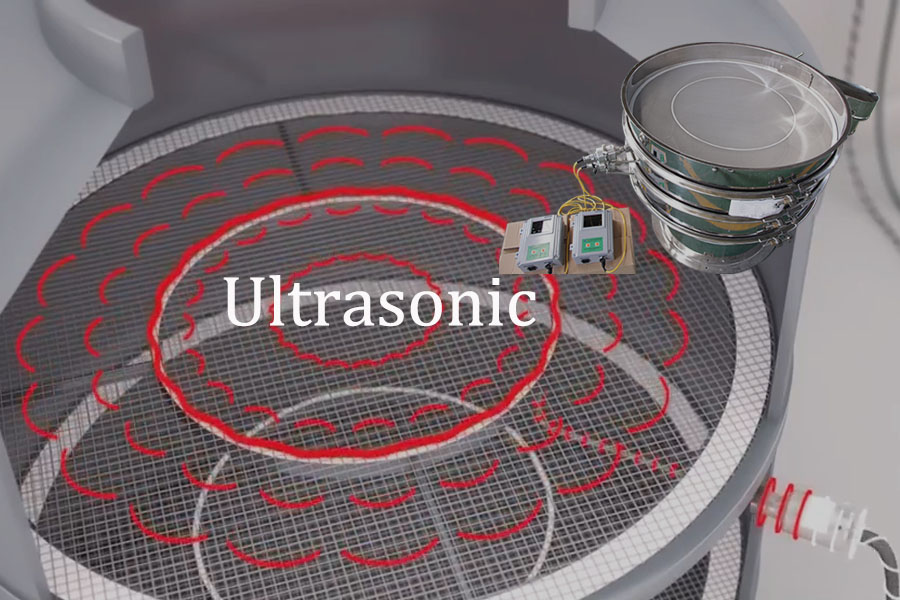

What is ultrasonic sifter

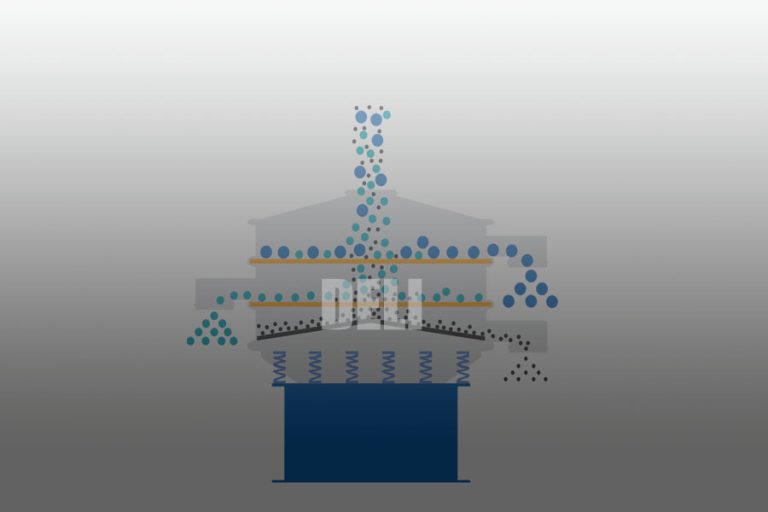

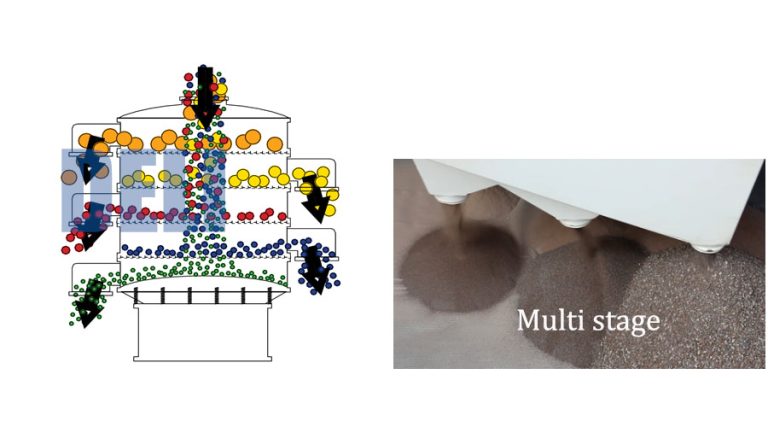

Ultrasonic vibrating sifter refers to a vibrating sifter with ultrasonic screen cleaning function. It is based on the traditional circular vibrating sifter and adds an ultrasonic screen cleaning device.

It solves the problem of mesh clogging

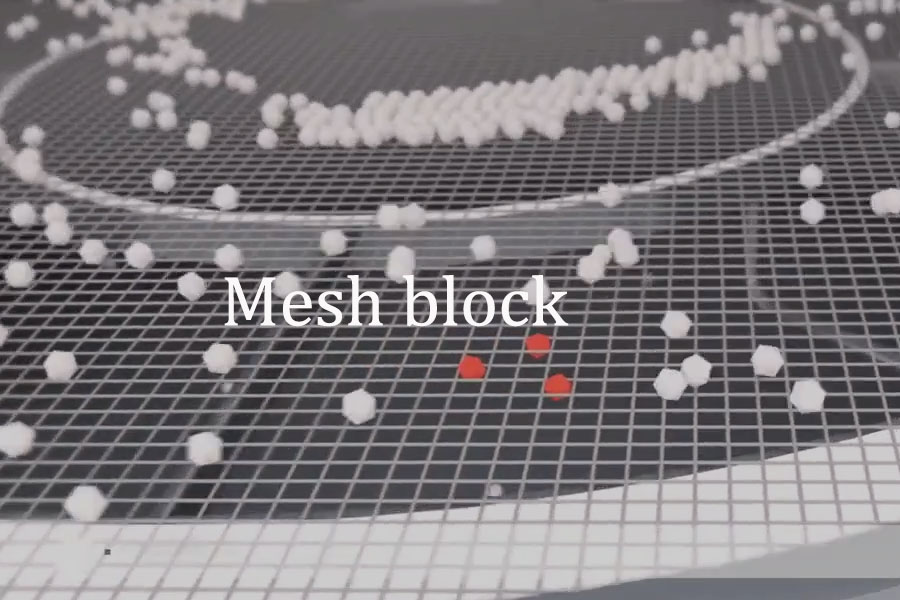

Blockage of the mesh will reduce the screening efficiency, so it is necessary to ensure that the mesh is always open. The ultrasonic vibrating screen applies ultra-high frequency vibration of 36KHZ to the mesh. When the equipment is turned on, each mesh will vibrate, causing the materials stuck in the mesh to leave the mesh.

The difference between ultrasonic sifter and traditional vibrating screen

- Particle size.

The particle size range that the ultrasonic vibration sifter can process is 10 mesh ~ 600 mesh / 20 micron ~ 2 mm. The vibrating screen equipped with a bouncing ball screen cleaning system can only screen powders of 10 mesh to 200 mesh / 75 micron to 2 mm. The former can handle finer particles and powders. - Efficiency and output. Because the frequency of ultrasonic waves is higher, reaching 36ghz, which is much higher than that of bouncing balls, the production capacity of ultrasonic vibrating screens is higher.

- Adaptability. Ultrasonic vibrating screen can adjust the frequency of ultrasonic waves, and vibrations of different frequencies will adapt to different material screening needs.