Introduction

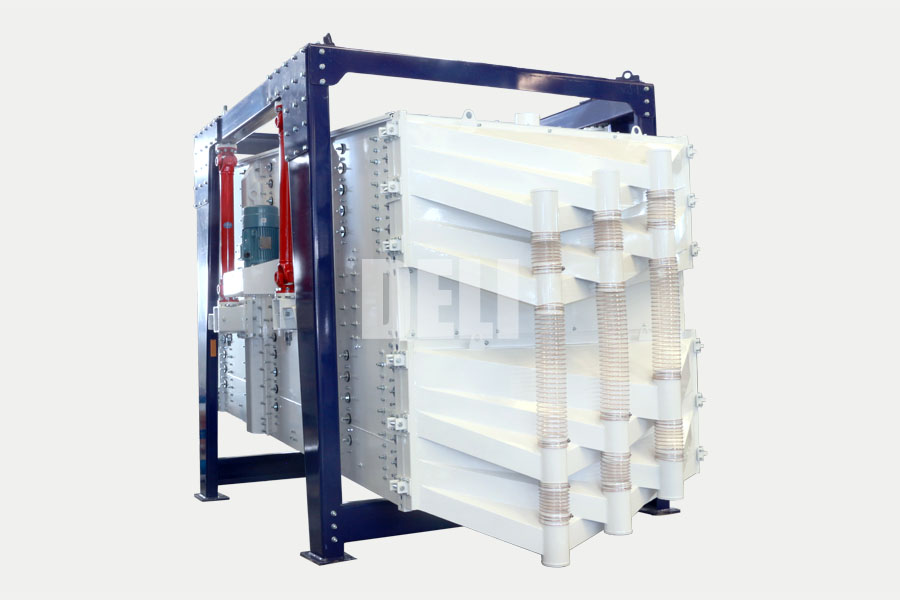

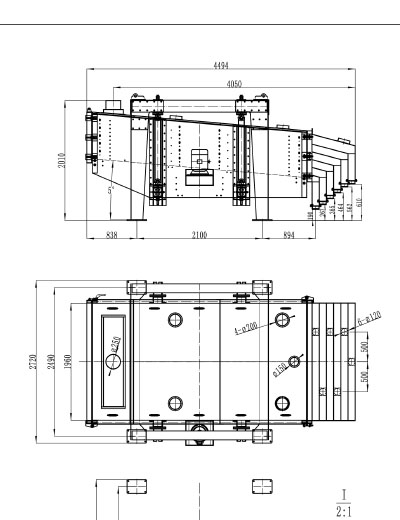

Model NO.: 4G2036-2P

Screen size: 6.6 feet width, 11.8 feet length

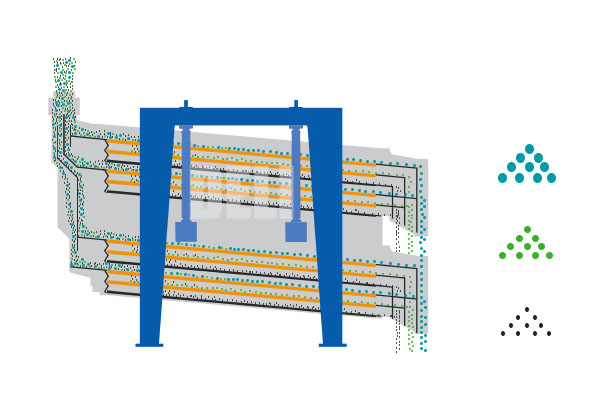

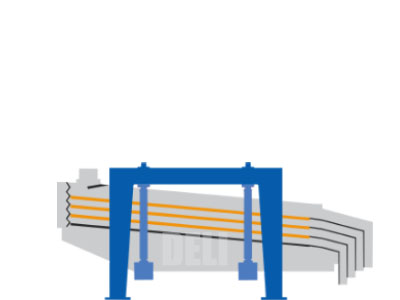

gyratory screener Working princeple

The elliptical motion trajectory enables the gyratory screener to identify a minimum particle size of 170 mesh (90 microns), while the maximum processing capacity reaches 20 tons per hour. This is an all-round screener machine for fine powders.

The material is flatly spread on the screen surface at the inlet, and then moves forward to the outlet in an elliptical trajectory.

The advantage of the elliptical motion trajectory is that compared with the rectangular vibrating screen, the material is thrown to a smaller height and the material stays on the screen surface for a longer time, which leads to improved screening efficiency. At the same time, its swing amplitude is as high as 40mm, and the huge kinetic energy improves the net clearing effect of the jumping ball, so it can still ensure that the hole is not blocked when processing 170 mesh fine powder.

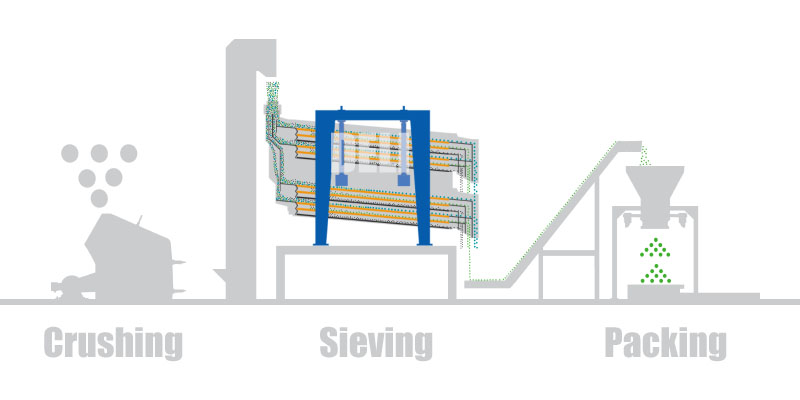

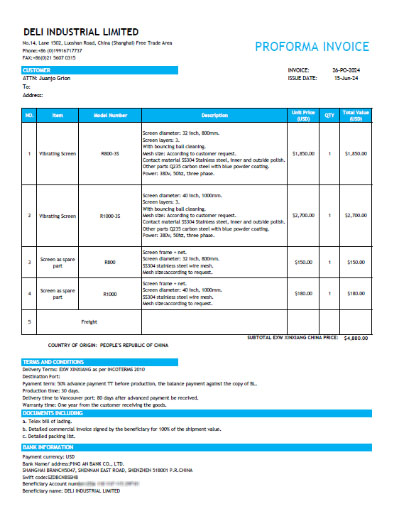

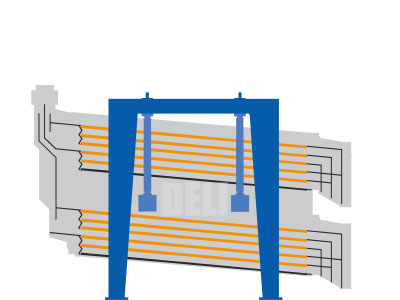

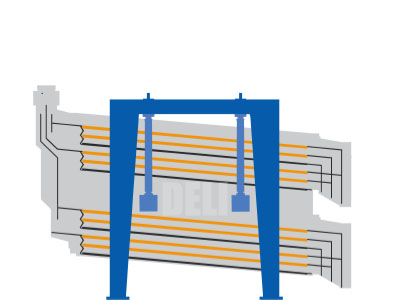

Position in the plant

Gyratory screener is compact in size, highly efficient, and easy to place in the production line, saving factory procurement costs.

4G2036-2P gyratory separator covers an area of 5m * 4m * 4m, which is compact and can be well adapted to belt conveyors and bucket elevators. The single-machine processing capacity of up to 20 tons can also match the output of grinding equipment.

We also provide design and manufacturing of work platforms. Please contact us for more production line layout cases.

Functions

Quick screen change

The quick-change structure on gyratory separator is designed to save plant maintenance costs and adapt to a variety of screening needs.

One operator can access the screen inside the device in less than one minute, and the process is tool-free.

Two operators can replace a new screen in less than 10 minutes, and the process requires an electric wrench.

Screen replacement time for different structures

| Screen structure | Time |

| Quick structure | 10 Minutes |

| Backward hook | 20 Minutes |

| Side hook | 60 Minutes |

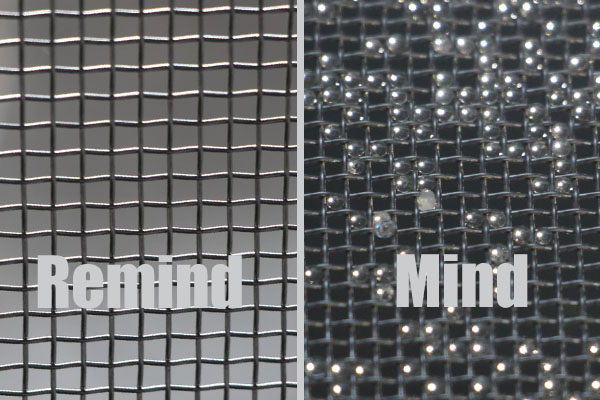

Remind mesh screen

Break through the limit and identify the minimum 170 mesh (90 micron) particle powder.

The ball-jumping net cleaning system of the 4G2036-2P gyratory separator can still work efficiently when the mesh size reaches 170 mesh, preventing mesh blockage. Traditional rectangular vibrating screens face problems of mesh blockage and screen damage when the mesh size is less than 70 mesh, while gyratory vibratory machine adopts a unique net cleaning system design, giving the mesh a stronger cleaning ability, breaking the mesh lower limit to 170 mesh.

Remind screen advantages

Optimized rebound mode

The wave-shaped ball support plate of the gyratory vibratory machine improves the bounce trajectory of the ball, ensuring that the screen in each area is cleaned.

The special-shaped ball reduces the working dead angle.

70% rebound capacity silicone balls.

Durable performance, longer screen service life

The tension adjustment funtion and the seal of the ball support plate make the tension of the screen uniform and tight, reducing the deformation of the screen caused by material backlog and extending the service life of the screen on the gyratory vibratory machine.

Specification

| Model NO. | Screen Size / MM | Deck Quantity | Stack |

| G1536 | 1500*3600 | 1~6 | No |

| G2036 | 2000*3600 | 1~6 | No |

| 2G1536 | 1500*3600 | 2~12 | Double |

| 2G2036 | 2000*3600 | 2~12 | Double |

| 4G2036 | 2000*3600 | 4*2 | Four times |

| 6G2036 | 2000*3600 | 6*1 | Six times |

Model list

G2036-3

G2036-5

2G2036-5

4G2036-2