Table of Contents

vibro sifter principle

Vibro sifter principle is to use three dimensional vibration to seprate the material into products of different particle sizes. Watch the video on how vibro sifter work:

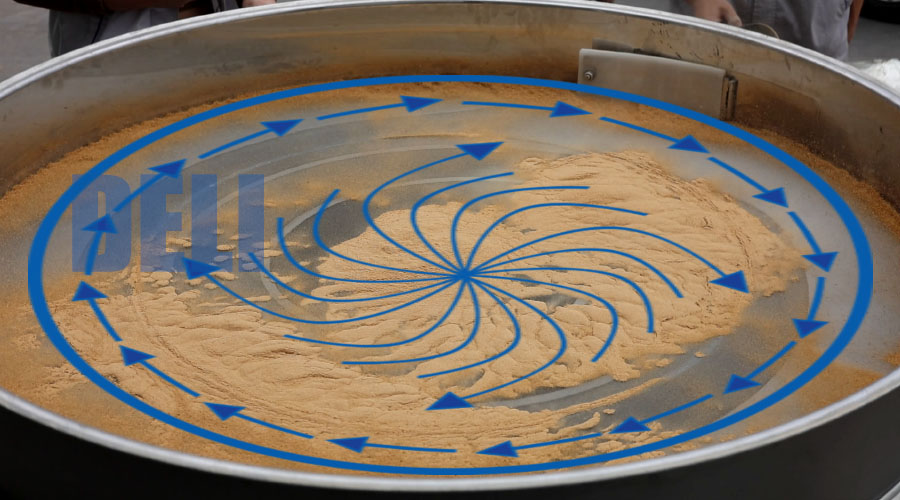

three dimensional vibration principle

During the machine running, the vertical vibrating motor with eccentric blocks at both ends generates a combined force, which is a synthesis of forces in three directions: radial, longitudinal, and transverse. Under the action of the combined force, the product spreads from the center to the surrounding along the arc trajectory on the net screen. We call this principle the three-dimensional vibration. The figure below shows this combined force.

Advantages of three-dimensional vibration principle

high flow per unit area net.

The mesh screen area of the circular vibro sifter is the smallest among all vibrating screens. It is difficult to achieve higher separation output on a smaller screen surface. The three-dimensional movement extends the sifting path, speeds up the sifting speed, and makes fuller use of every inch of the mesh screen.

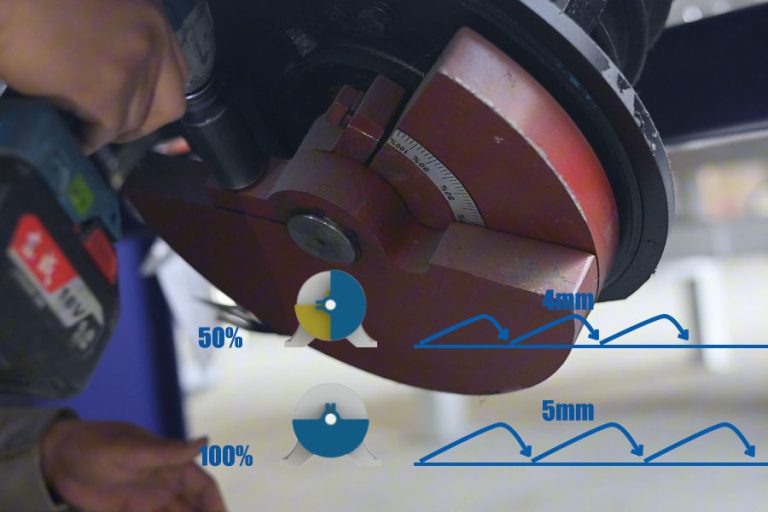

Sifting patterns is adjustable

Thanks to the principle of combined force, we can adjust the direction and strength of the combined force by adjusting the horizontal angle of the eccentric blocks at both ends of the motor, thereby changing the movement trajectory of the material on the screen surface. The following are three different sifting patterns.

Fast pattern, maximum output.

Balanced pattern, taking into account both output and efficiency.

Extreme pattern, highest efficiency.

The vibro sifter separates the product into different particle size

What is the size sepration

Products of different particle sizes are mixed together, and the vibration sifter separates the products within a specific particle size range. This is called size separation.

Size is an important performance indicator of powder and granular products, which determines whether the product is qualified. The following are the size requirements of different products.

| Product name | Particle size range / Microns |

| Flour | 200~1000 |

| Protein powder | 100~300 |

| Aluminum powder | 45~180 |

| Red wine lees | 28~500 |

How to sifting

During the sieving process, the product enters the screen, small particles pass through the mesh to the next layer of separation, and large particles remain on the screen surface and are discharged.