Introduction

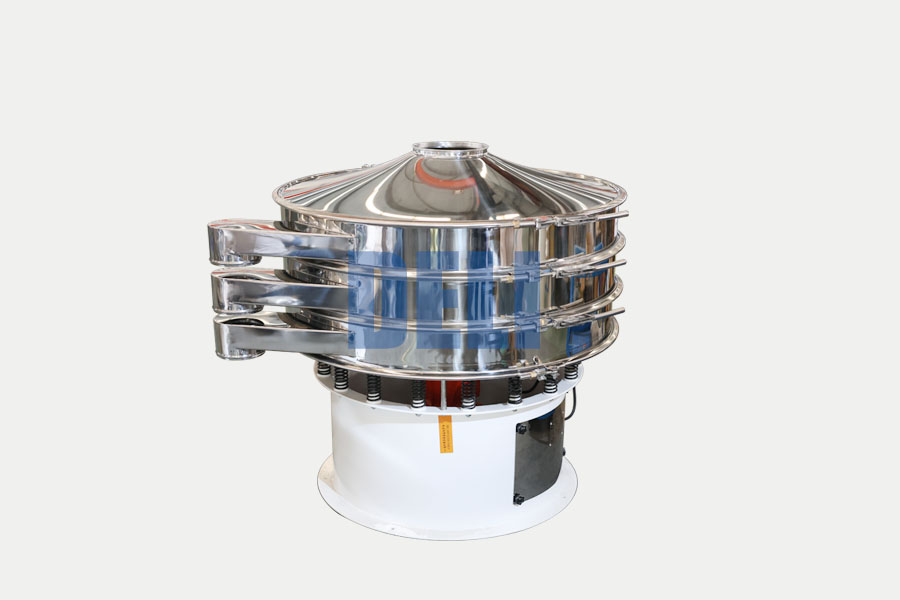

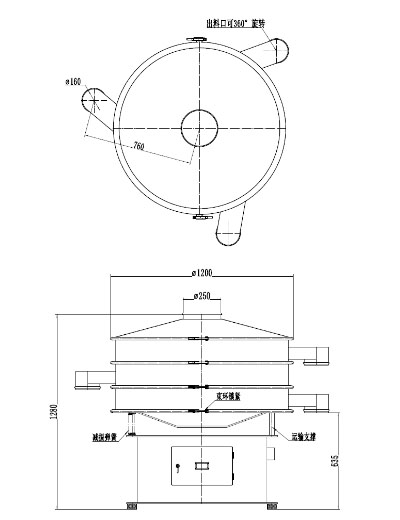

Model NO.: R1200-2S

Diameter: 48 inch / 1200mm

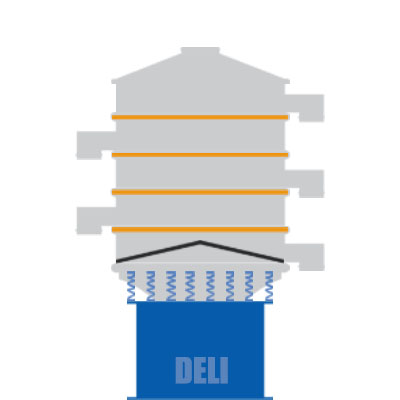

Working princeple

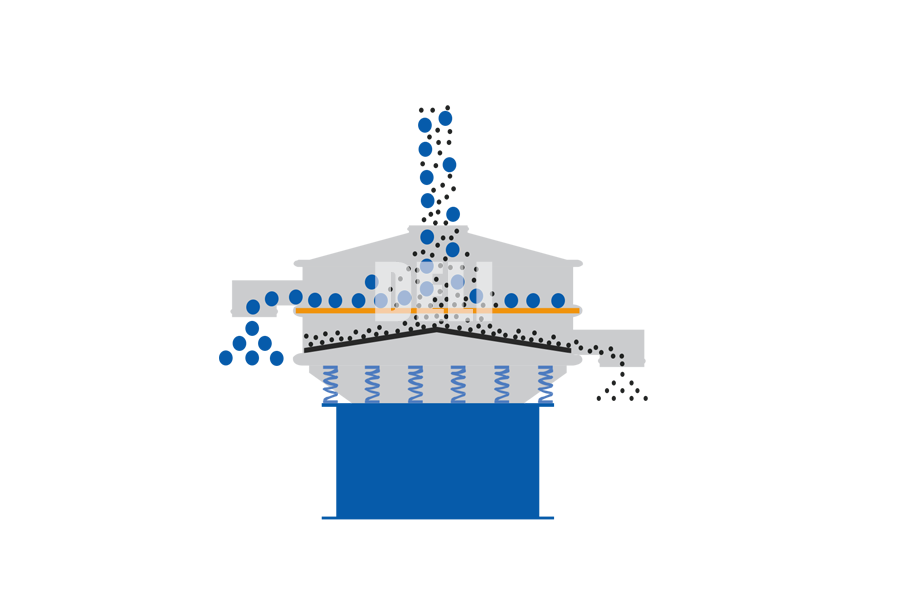

The circular vibratory screener uses the mesh size to physically separate the material. Particles larger than the mesh remain on the screen, and particles smaller than the mesh pass through the mesh to the next layer. In this process, the vertical vibrating motor drives the screen to do a compound movement, which accelerates the screening process. This machine screen is round shape, we also call this machine round vibratory separator.

The circular vibratory screener can be equipped with up to 5 layers of screens to separate the material into 6 different sizes of products according to the particle size.

Position in the plant

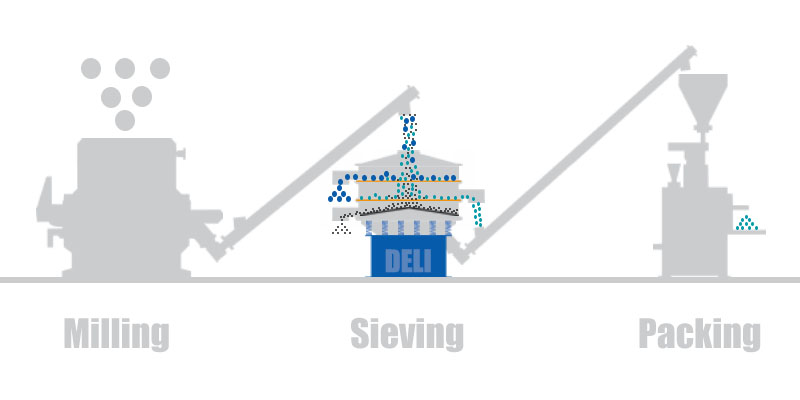

Circular vibratory separator is a necessary equipment in food processing and chemical processing. In the processing plant, its upstream equipment is crushing, grinding, milling or mixing equipment, and its downstream equipment is packaging equipment.

The role of the circular vibratory separator in the processing machinery is physical separation, that is, separating the product into different specifications according to the particle size.

For example, in food processing, after milling, the powder incudes different particle size granule, sieving processing will separate small dust and large impurities from the qualified powder, finally the factory obtains medium-sized powder. Know more about the vibrotry sieving application.

Functions

Quick release clamp

Round vibratory separator has the quick release clamp design, by which, users can increase or decrease the number of screens to get more sepration fraction, for example, when you mount extra screen and spacer on the one deck vibratory separator, you will get a two-deck vibratory separator. Meanwhile, quick clamp ring design allows the maintain work easily when you replace screens with different meshes and check the mesh cloth status.

Five steps to change the screen

Open the clamp without tools.

Remove spacer.

Take out the screen and put new screen.

Mount the spacer.

Lock the clamp ring.

vibratory force adjustable

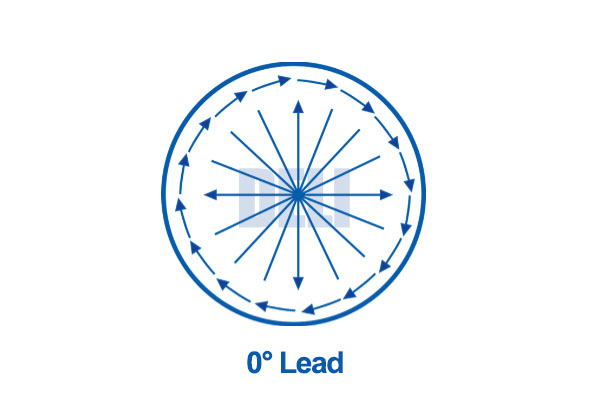

The round vibratory separator can separate different products with different sieving motion patterns. The drive system consists of a motor and counterweights at both ends of the motor shaft. By adjusting the weight angle, you can switch between different motions. Each sepration motion has a specific purpose depending on the sieving requirements of your product.

Vibration Motion

0 degree motion

Fastest sieving speed. The product stays on thesieve surface for a short time, which may result in insufficient sifting.

15 degree motion

Classic Motion Suitable for most products. Yield and screening quality are maximized.

60 degree motion

Maximum Efficiency. The product stays on the screen surface longer time and is fully sieved. Suitable for dry and wet products.

Specification

| Model NO. | Diameter | Deck Quantity | Exciting force |

| R600 | 24 inch | 1~4 | 5 Kn |

| R800 | 32 inch | 1~4 | 8 Kn |

| R1000 | 40 inch | 1~4 | 11 Kn |

| R1200 | 48 inch | 1~4 | 15 Kn |

| R1500 | 60 inch | 1~3 | 40 Kn |

Model list

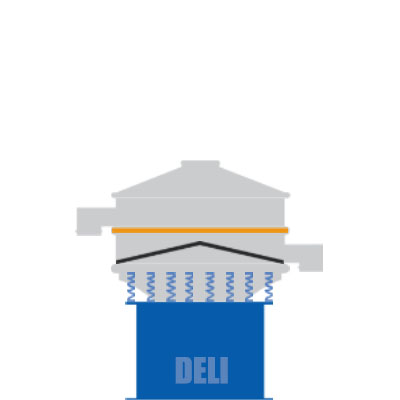

R1200-1

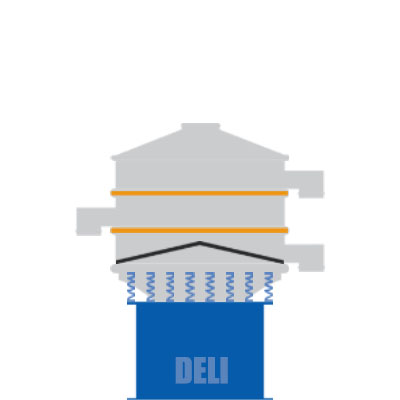

R1200-2

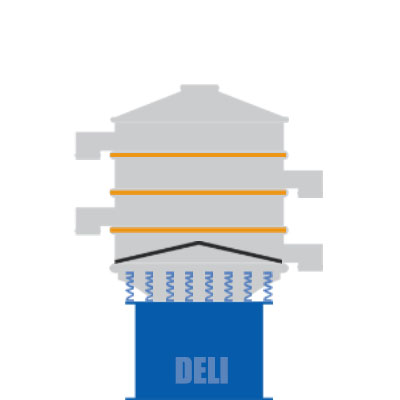

R1200-3

R1200-4