Introduction

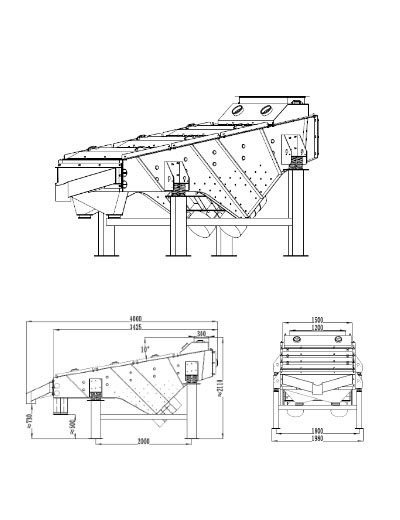

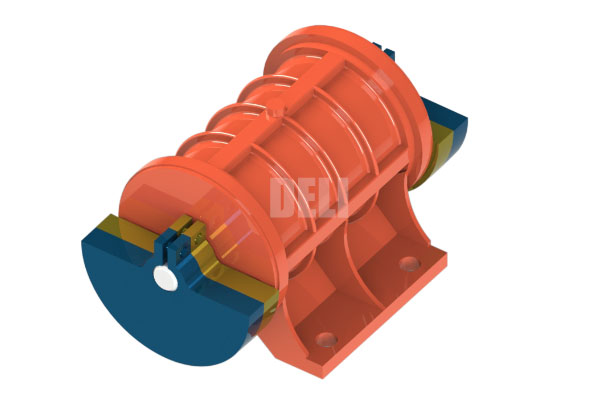

Model NO.: GLS2036-2

Screen size: 2000*3600mm

Working princeple

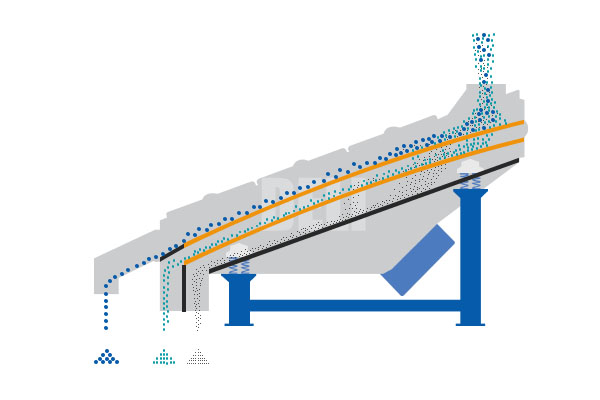

The working principle of GLS vibratory screener machine is similar to that of linear vibro separator machine, both of which use the principle of vibration and mesh size to separate materials into products of different sizes.

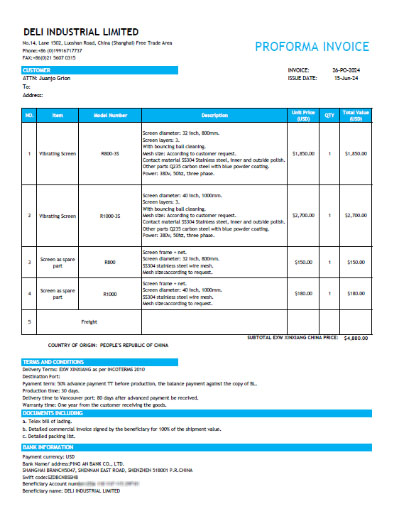

The uniqueness of GLS vibrating screen is that it can process up to 200 cubic meters per hour, and the equipment only occupies 10 square meters of space (including safety area). This is due to the 20-degree screen angle and heavy-duty structural design. The larger screen angle allows the material to flow faster, and the enhanced structural design allows the vibratory screener machine to carry more material.

Features:

1. Large inclination screen.

2. Quick maintenance of screen.

3. Output up to 200 cubic meters or 100 tons/hour.

4. Small size, minimum screen surface 2 square meters.

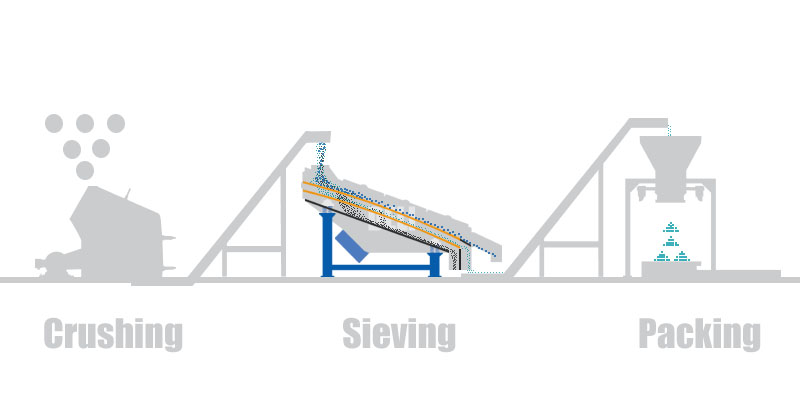

Position in the plant

Thanks to the processing capacity of up to 100 tons per machine, the GLS vibratory screener machine can be placed downstream of large crushers, grinding equipment, extruders, and wood chippers, and can be used with large belt conveyors or bucket elevators.

The value it provides you:

1. Reduce the number of screens and save on-site space.

2. Streamline the area occupied by the production line.

3. Save the number of conveying equipment and reduce procurement costs.

4. Facilitate maintenance and reduce downtime.

Functions

Quick maintainess of screen

The industrial vibratory separator uses a unique hook structure to fix the screen inside the screen machine. When the user needs to check the condition of the screen or replace the screen, the user only needs to open the door and take out the screen by adjusting the bolts. This process does not require the removal of bolts or additional tools. Only two operators and a general electric wrench are needed.

The benefits of hook screen structure

Quick release of the screen deck saves downtime.

Each deck can be released individually to save maintenance time.

User-friendly adjustment of screen tension prolongs the service life of the screen.

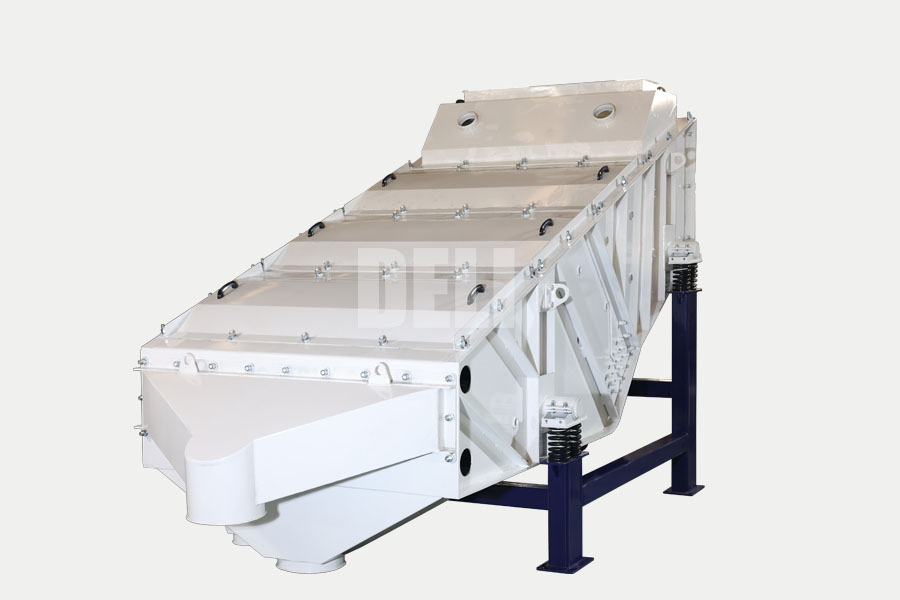

Screening patterns adjustable

The exciting force of the vibro separator machine is adjustable. Two eccentric blocks are configured at each end of the motor. The larger the angle of the two eccentric blocks, the greater the exciting force generated by the motor.

The exciting force affects the speed at which the product passes through the industrial vibratory separator and the effect of preventing hole blocking.

Separating patterns

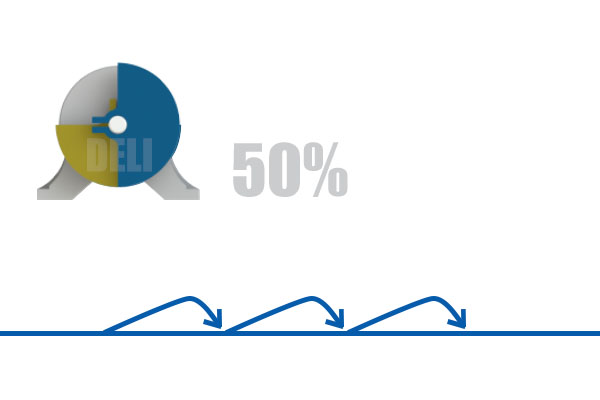

50% pattern

Low speed mode. The amplitude is low, the material moves slowly on the screen surface, and the height of the material is low, which is suitable for materials with light specific gravity.

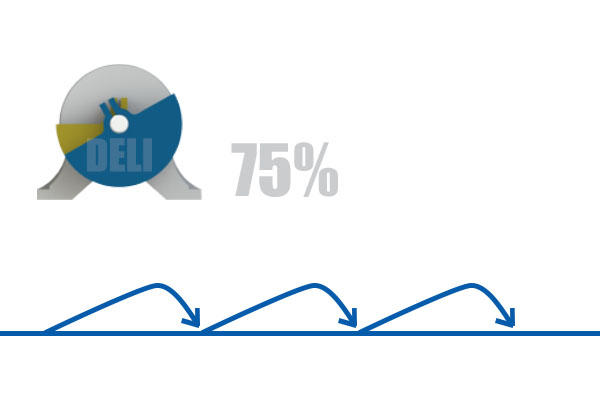

75% pattern

Balanced mode. Higher amplitude, higher screening output. Suitable for most materials.

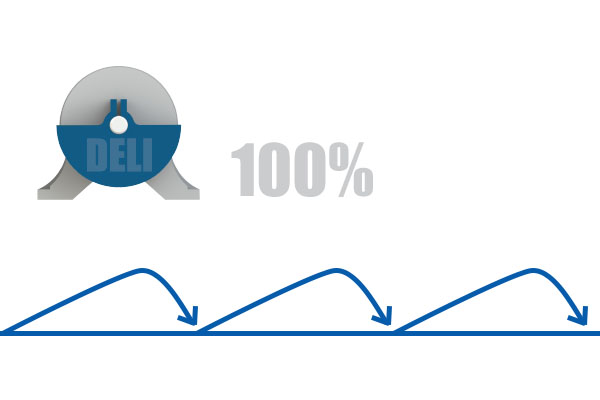

100 pattern

Powerful mode. Highest amplitude, highest output and strongest screen cleaning effect.

Specification

| Model NO. | Screen Size | Deck Quantity | Exciting force |

| GLS1020 | 1000*2000 mm | 1~3 | 40 Kn |

| GLS1225 | 1200*2500 mm | 1~3 | 40 Kn |

| GLS1230 | 1200*3000 mm | 1~3 | 40 Kn |

| GLS1536 | 1500*3600 mm | 1~5 | 50 Kn |

| GLS2036 | 2000*3600 mm | 1~5 | 60 Kn |