YBS tumbler Screening machine

yBS1500-2S Introduction:

YBS tumbler screening machine is an industrial machine that sieves and grades powders and granules according to the size of the product. It is characterized by high screening efficiency and small size. It is mainly used in the food, chemical and mineral industries.

YBS1500-2S is made of SS304 stainless steel material and reaches food contact grade.

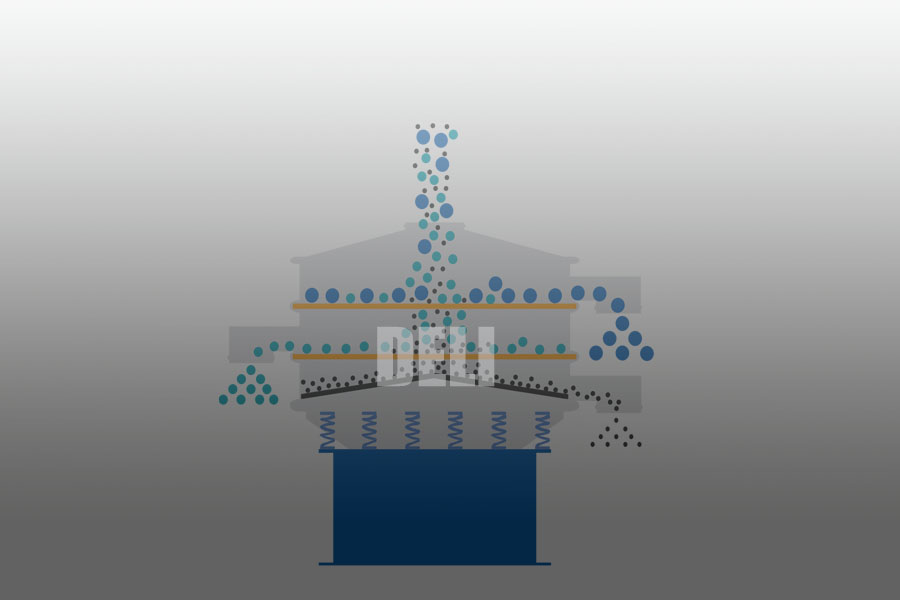

Tumbler screening machine working principle is that the motor drives a set of eccentric bearings to rotate, and the bearings drive the screen to do radial and longitudinal swinging motion. When the product enters the screen, the product rotates and rolls on the screen surface, small product will pass through the net and big particle will stay on the screen. This Tumbler motion trajectory allows the product to stay on the screen surface for a longer time. At the same time, the rolling motion allows the product to fully contact the screen and obtain greater screening opportunities.

YBS1500-2S can reach a processing capacity of 1500kg/hour when it uses two decks of 100 mesh/150 microns and 200 mesh/75 microns to screen aluminum powder.

Working principle diagram

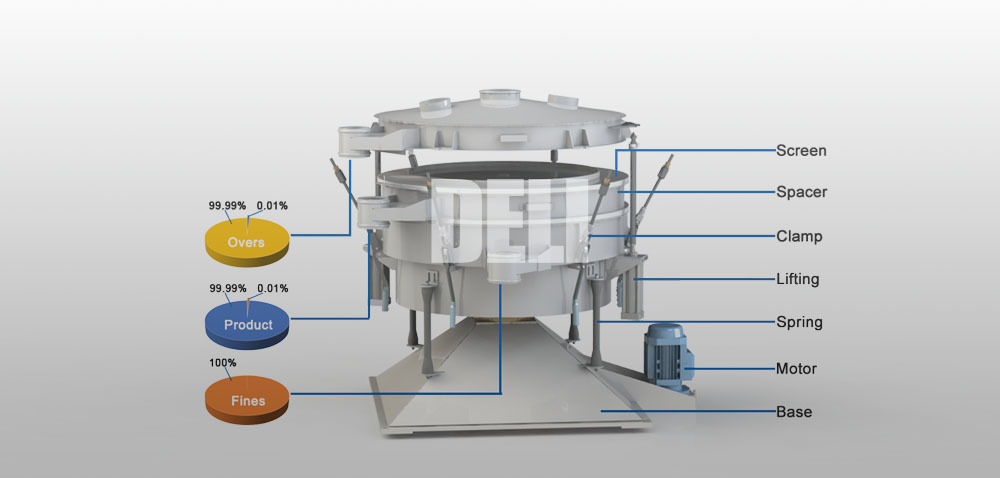

Structure

Features:

Self cleaning system. Ultrasonic cleaning system is optional.

Cylinder lift, quick access to equipment.

Capacity up to 5 tons per hour.

3 stage separating at the same time.

Tell 10~325 mesh (45 microns to 2000 microns).

Specifications

| Material: | SS304 Stainless steel + Q235 carbon steel |

| Color: | Sand blast |

| Screen layer: | 2 |

| Outelet: | 3 |

| Screen diameter: | 1500mm / 60 inch |

| Mesh: | SS304 Stainless steel wire mesh |

| Mesh size: | 10~325 mesh, 0.045mm ~ 1mm |

| Mesh cleaning: | Bouncing ball / Ultrasonic |

| Voltage: | 380~690v, 50/60hz, three phase |

| Bearing: | ABB |

| Power: | 0.25Kw, 5KN |

| Rotate speed: | 1400 Rpm |

| Max Inlet: | 3000 kg per hour (powder, bulk desity 0.8, mesh size: 1mm, 2mm, 3mm) |

Product brochure download

Tumbler screening machine catalog

YBS1500-3S Tumbler screening machine Drawing

Application:

Salt, sugar, aluminum powder, alloy powder, electrode powder, titanium dioxide, Silicon metal.