Introduction

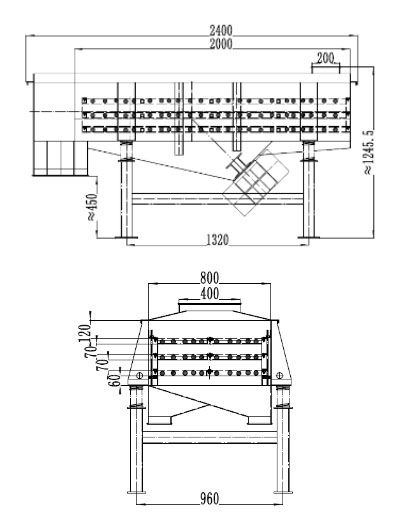

Model NO.: L0820-1S

Screen size: 800*2000mm

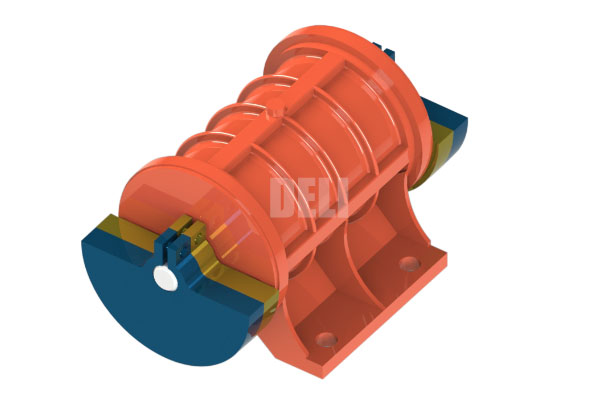

Working princeple

Linear vibrating screener is a large capacity retangular separating machine, it uses vibration and mesh size to screen the products into different particle size. When the material is put into the linear vibrating screen machine, it moves along the straight line on the screen surface. In this process, small particles pass through the mesh holes and large particles remain on the screen surface. Finally, these two types of materials are collected through the discharge ports to achieve the purpose of screening.

The linear vibrating screener is characterized by large output and can be customized. The output particle size range is 0.3mm to 10mm (2 mesh to 50 mesh).

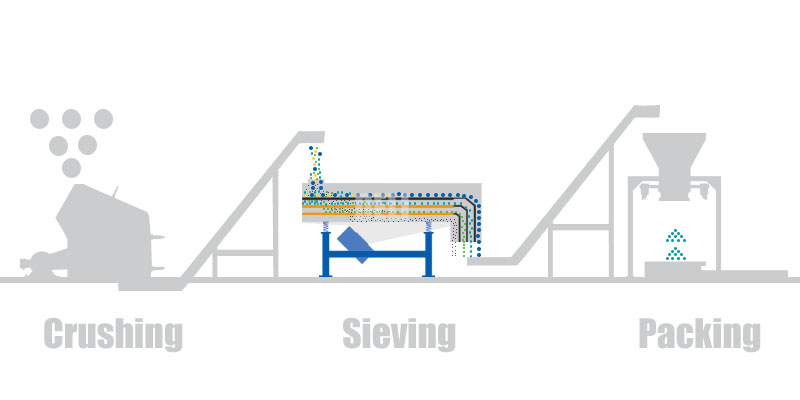

Position in the plant

The linear vibrating screen machine can process up to 20 tons per hour or 50 cubic meters per hour and can be placed after the crusher and before the ton bag packaging machine.

This sieving machine is used to classify the crushed particles and powder.

A classic screening method is equipped with 3 decks to screen the material according to the particle size into 4 different sizes of finished products:

1. Dust (waste)

2. Small particles

3. Medium-sized particles

4. Large particles return to the crusher

Functions

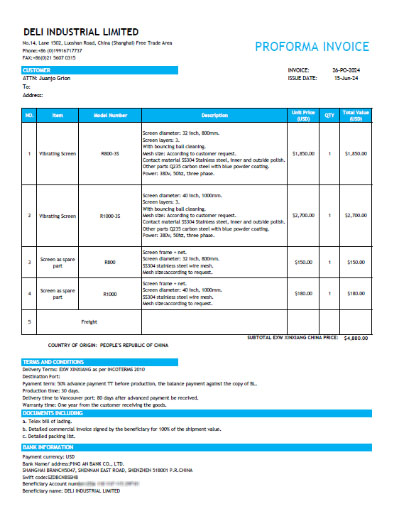

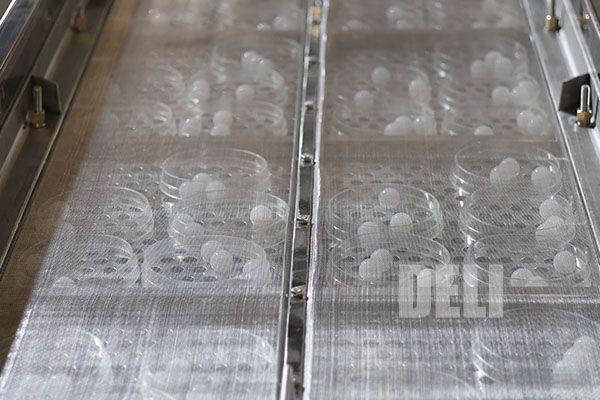

Self-cleaning mesh screen

This self-cleaning mesh screen structure consists of a screen, a bouncing ball and a ball plate. The vibration of the linear vibrating screen machine provides power for the bouncing ball moving, which bounces between the ball plate and the screen and hits the mesh, removing the particles blocked in the mesh.

The advantage of the self-cleaning screen is high screening efficiency.

When the mesh size is less than 1mm or the material shape is irregular, the mesh is very easy to be blocked, which will have a serious consequence that some small particles cannot pass through the mesh and are collected together with the large particles, and the large particles and small particles in the finished product cannot be completely separated.

The benefits of anti-blocking structure

1. Higher output, cost savings.

2. No need to manually clean the mesh, saving downtime.

3. Reduced impurities in the product, improved product competitiveness.

4. The minimum particle size of 300 microns can be identified, no secondary screening is required, saving procurement costs.

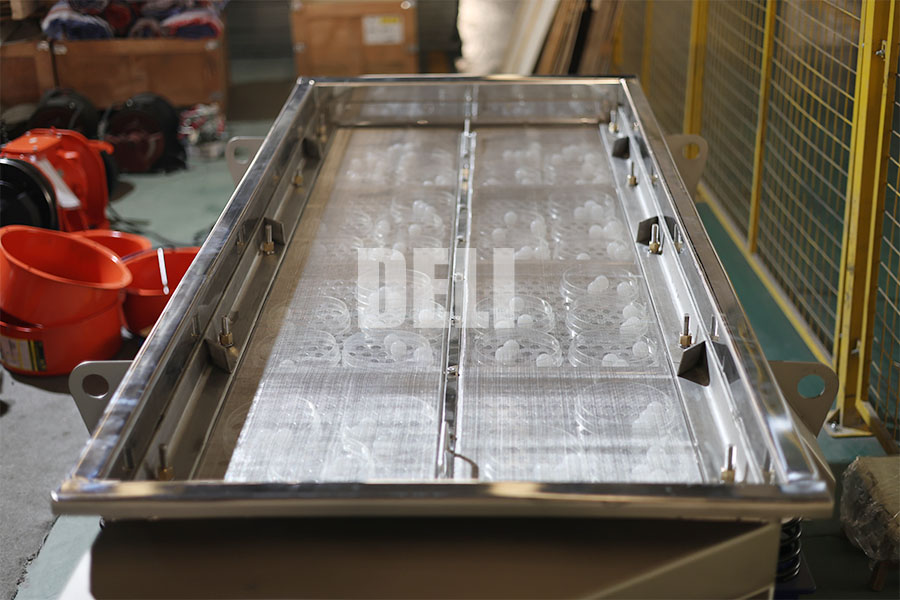

Screening patterns adjustable

The linear vibrating sieve machine supports infinite amplitude adjustment, ranging from 0% to 100%.

The amplitude is proportional to the output. The higher the amplitude, the faster the material moves on the screen surface and the stronger the net cleaning effect.

The amplitude adjustment function solves the adaptation problem for the factory:

1. When the output of upstream equipment increases, the factory can increase the output of the vibrating screen by itself.

2. When the moisture content of the product increases due to environmental influences, the problem of sticking to the net and blocking the holes can be solved by increasing the amplitude.

3. It is convenient for the factory to test the appropriate amplitude and screening effect according to its own material characteristics.

Screening patterns

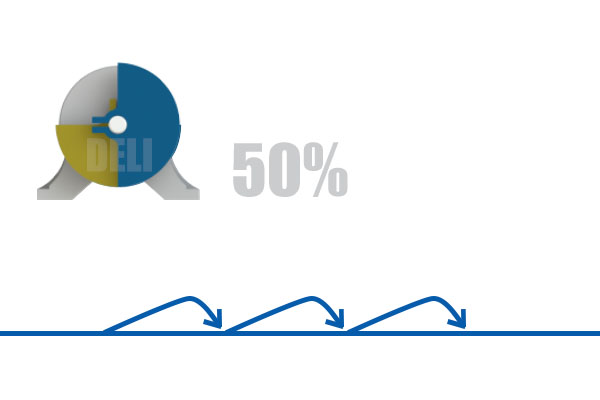

50% pattern

Low speed mode. The amplitude is low, the material moves slowly on the screen surface, and the height of the material is low, which is suitable for materials with light specific gravity.

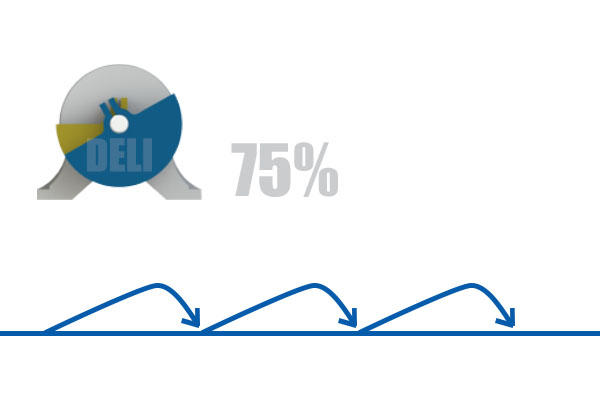

75% pattern

Balanced mode. Higher amplitude, higher screening output. Suitable for most materials.

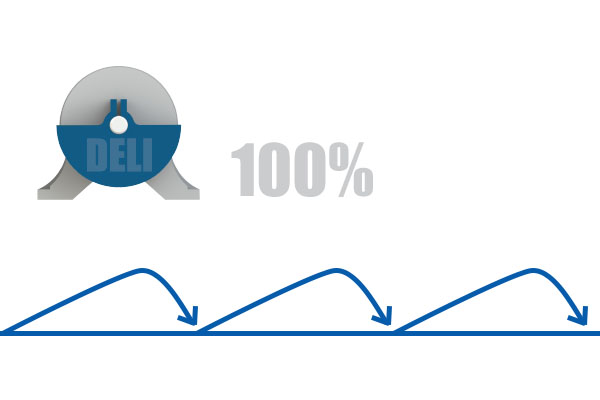

100 pattern

Powerful mode. Highest amplitude, highest output and strongest screen cleaning effect.

Specification

| Model NO. | Screen Size | Deck Quantity | Exciting force |

| L0520 | 500*2000 mm | 1~4 | 5 Kn |

| L0820 | 800*2000 mm | 1~4 | 11 Kn |

| L1025 | 1000*2500 mm | 1~4 | 16 Kn |

| L1530 | 1500*3000 mm | 1~4 | 47 Kn |

| L2040 | 2000*4000 mm | 1~3 | 65 Kn |