This article mainly introduces you to the differences of Gyratory screen and the choices for practical use.

Table of Contents

Gyratory screeners

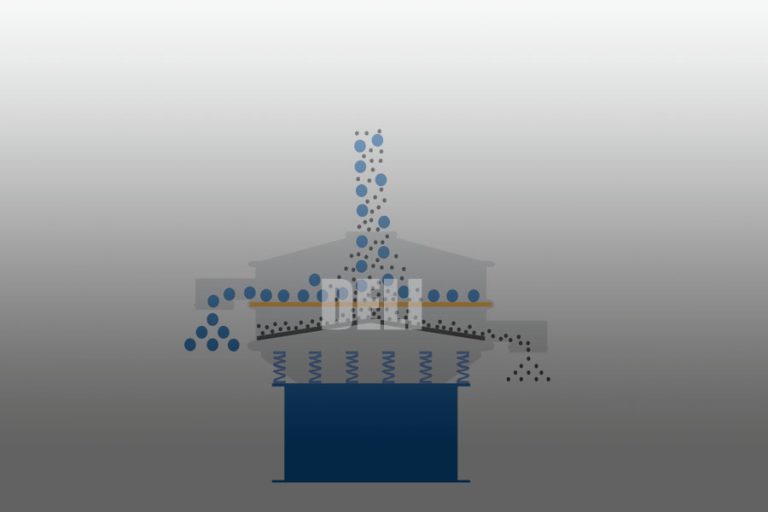

Gyratory screener has many names, such as Gyratory sifter, Rectangular swing screen, Gyratory separator, etc. Its most significant feature is the gyratory motion, that is, the movement trajectory of the material on the screen surface includes but is not limited to gyratory motion. Names include elliptical motion, zigzag motion.

What is gyration motion.

One of the most popular explanations is that two people hold both ends of a primitive sieve and shake the sieve at the same time. Some particles are placed on the sieve. The particles will move back and forth on the sieve. In the process, small particles fall through the mesh, and large particles Retain on sieve. This reciprocating motion is called a gyroscopic motion.

The video below shows the rotation trajectory. You can see that the product enters the screen from the feed port and moves along the zigzag path on the screen surface to the discharge port. During product movement, small-sized products pass through the mesh, while large-sized products are retained on the screen surface. This is the trajectory of the gyration motion.

The early vibrating screens used linear motion trajectories, and the products moved along a straight line on the screen surface in a parabolic trajectory. Compared with the linear motion trajectory, the rotary motion trajectory allows the product to run a longer path on the screen surface, thereby obtaining more complete screening! Therefore, theoretically, the gyratory motion trajectory leads to higher screening efficiency.

Types of gyratory screens.

Rotex MEGATEX XD, SWECO’s ATLAS, and fertilizer vibrating screen can all be called gyratory screens.

What they have in common is:

- Rectangular screen.

- The screen is suspended on the bracket.

- A motor drive.

- Inclined screen surface.

- Imitating manual screening, the screen surface makes a rocking motion.

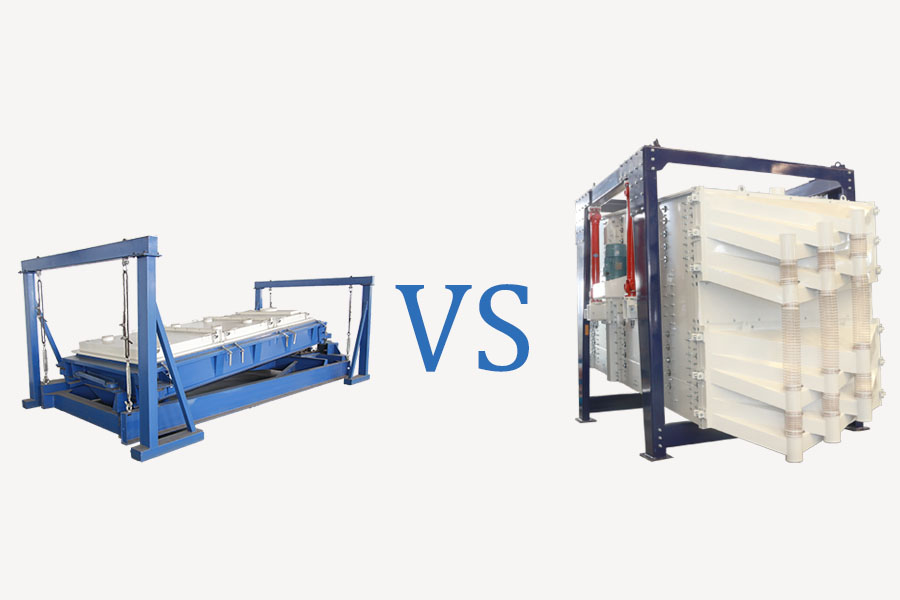

The difference between gyratory screens:

In short, these three types of equipment seek different balance points between the two factors of output and screening efficiency.

- Rotex gyratory screener has the highest output and is suitable for screening medium-sized products.

Megatex includes a rotary motion design, as well as circular motion and linear motion trajectory designs. It has two advantages. First, the linear motion trajectory shortens the time for materials to pass through the screen, so the equipment output is higher; second, the equipment swings more widely, so the equipment output is higher. - The advantages of the fertilizer vibrating screen are similar to the Rotex gyratory screener, but it has a unique advantage, that is, the structure is simpler, the cost is lower, and the cheapest price.

- Sweco gyratory sifter can screen products with smaller particle sizes. Because this design allows the material to move the longest path on the screen, obtaining the most adequate screening.

How to choose a gyratory screener?

First and foremost, the most important factor is budget. The price difference between the above three types of gyratory screens is more than 5 times. Before choosing the equipment, make sure which equipment is within your budget.

Secondly, determine the mesh size or product particle size. If the smallest product particle size exceeds 100 mesh, it is recommended to directly consider Sweco gyratory sifter. For Rotex products, if you use a screen with mesh openings above 100 mesh, you will not be able to tolerate the clogging. On the contrary, if the largest product particle size exceeds 5mm, it is recommended not to consider the Sweco gyratory sifter, and the other two devices will be better choices.

Of course, please consult our experts for specific cases.