Table of Contents

what products we manufacture

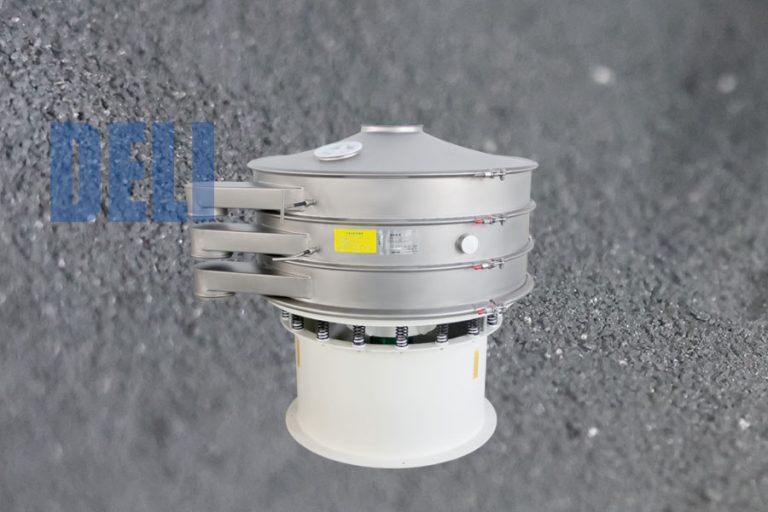

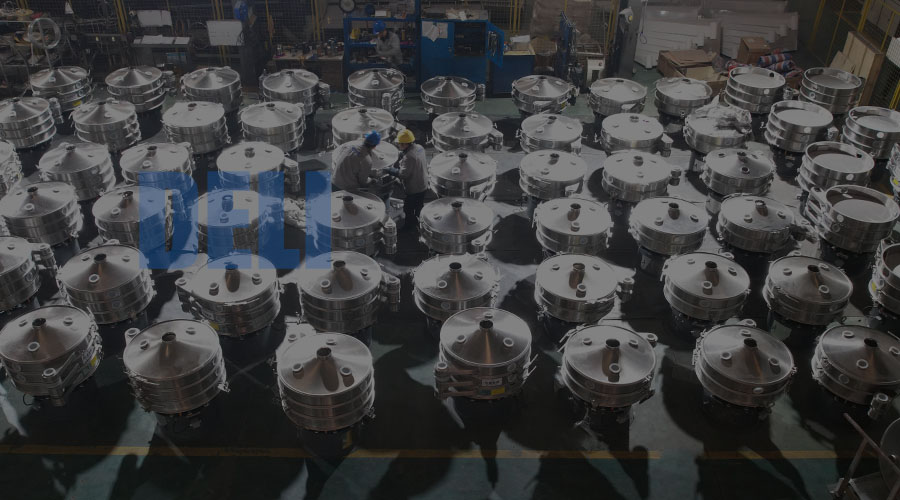

We provide design, production, manufacturing, testing, packaging, transportation and after-sales service for sanitary vibration sifters. Our production base is located in Xinxiang City, Henan Province, China, and we can manufacture 50 circular vibratory sieving machines and 5 rectangular vibrating screeners every day. Our service tenet is to deliver durable vibration sifters and save customers time and cost.

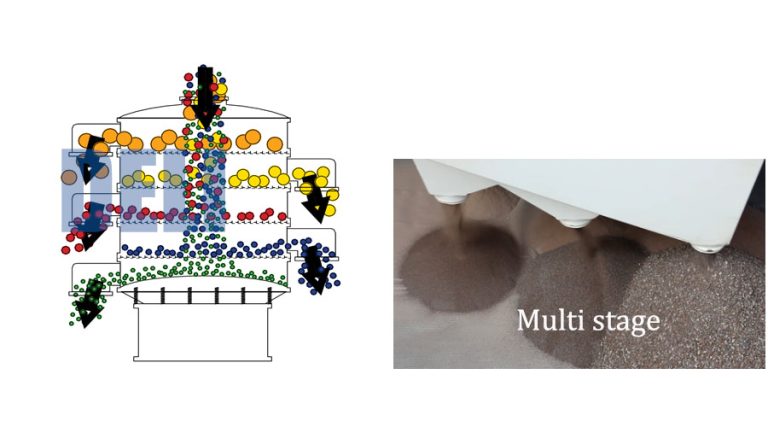

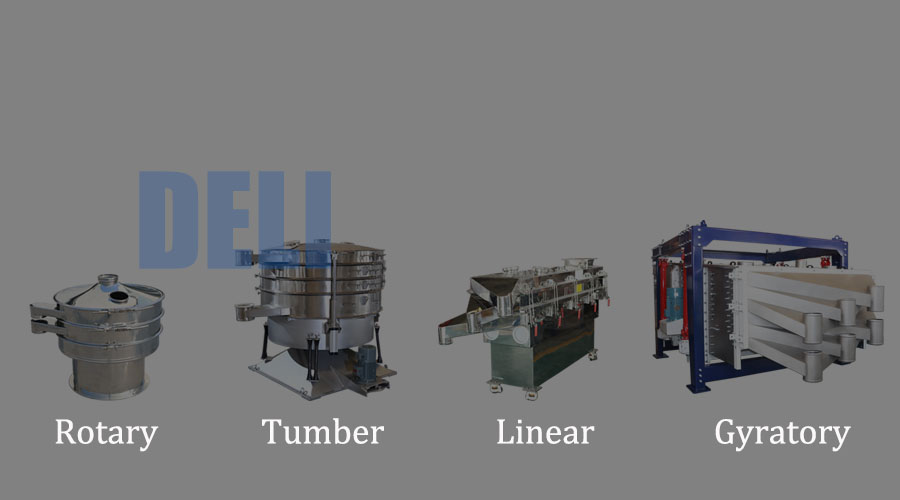

Our products include vibro sifter, ultrasonic sifter, linear vibratory screener, gyratory screener. All of them can be used in the separation process of food products with 10#~325# / 2mm~45 microns particle size.

sanitary screener manufacturer should have the following conditions

- Clean and tidy manufacturing workshops and production processes.

- Have qualified suppliers of food contact grade materials. And the certificates of machine material are required.

- Experienced polishing workers and stainless steel surface treatment equipment.

- More than 10 years of experience in manufacturing large quantities of sanitary vibration sieve machines, The market has verified the performance of the product.

The difference between sanitary screener and ordinary vibrating screen

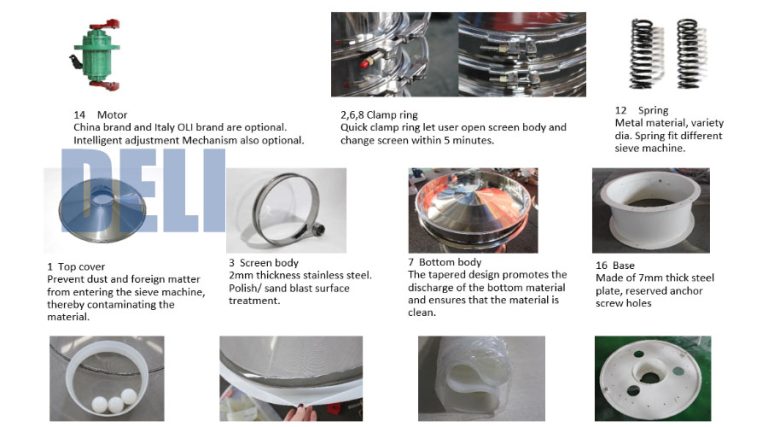

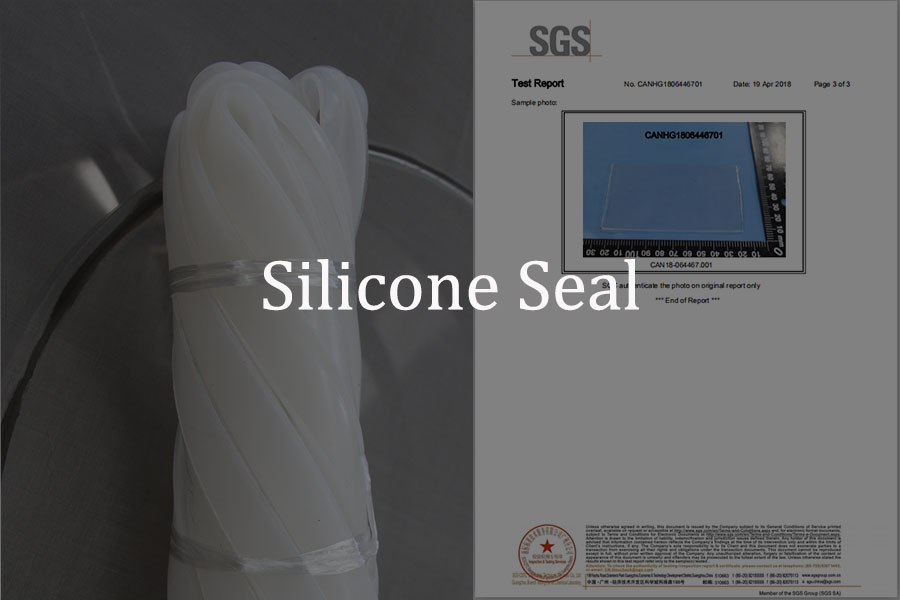

Material. The parts of sanitary screener that contact the material, such as screen, screen frame, seals, and screws, must meet the food contact grade, while non-food-grade vibrating screens do not have this requirement.

A confusing question is whether a vibrating screen made of stainless steel is a sanitary screener manufacturer? The answer is no, because the materials used to make sanitary screening machines include but are not limited to stainless steel.

The following are some introductions and testing standards for food contact grade materials.

| Item | Standard |

| Stainless steel | JIS-G-4305:2012 |

| Silicone parts | US FDA 21 CFR 177.2600 |

| Machine manufacture | EN ISO 12100:2010 |

Explosion-proof design. This is mainly for flour screening. The motor needs to meet dust explosion-proof standards, and the spring needs to be isolated from the outside world to prevent the heat generated by friction from being transferred to the flour.

Easy to clean. Sanitary vibrating sieve machines use a higher surface treatment process, smooth welds, and fewer internal dead corners, which makes it convenient for factories to clean the inside of the equipment and ensure the hygiene of the equipment.

Benefits you will get from the sanitary vibrating screen manufacturer

- Receive a hygienic sieving machine, no need to spend time cleaning the vibration sifter.

- Safe processing machine in your plant, traceable equipment raw material suppliers and certifications.

- Competitive product.