Table of Contents

What is vermicompost sieving machine?

The vermicompost sieving machine is an industrial machine used to separate earthworms, vermicompost, earthworm cocoons and soil impurities. This machine has the characteristics of automation, large output, high separation efficiency, no harm to earthworms, clean, water corrosion resistance, and easy maintenance.

When producing vermicomposting on a large scale, manual collection of vermicomposts is inefficient and risks damaging the earthworms. The sieving machine uses the principle of vibration to separate the smaller earthworm castings from the larger earthworms. The vermicompost is collected for sale, and the earthworms are collected and returned to the feeding tank. This screening process is automatic and can process 1 to 10 tons of earthworm powder per hour.

The difference between vermicompost and vermiculture.

The final products are different. Vermicomposting is one of the products of vermiculture. It is an organic fertilizer mainly used in agriculture, such as flower planting; the purpose of vermiculture is to produce earthworms.

However, with the improvement of technology, DELI vermicompost separator machine can complete the sepration of earthworms and compost at the same time.

The difference between vermicompost sifter and vermiculture sifter.

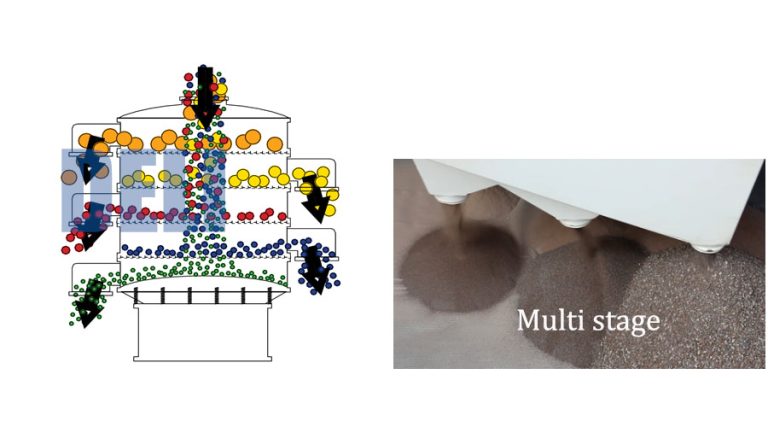

The vermiculture sifter is equipped with a layer of screen, the screening process is simple, and various sieve machines can do it; The vermicompost sifter is equipped with three layers of screens, the screening process is complicated, and few equipment works.

Because the size of earthworms is significantly larger than the rest of the materials, only one layer of screen is needed to separate the earthworms of the size from the culture materials to obtain clean earthworms. However, the separation process of vermicompost is much more difficult, because the aquaculture raw materials contain components of various sizes. We need to separate the earthworms, earthworm cocoons and soil impurities separately to obtain pure compost. The following are the different components in the aquaculture raw materials:

| Name | Particle Size | Stay on the screen deck |

| Earthworms | Diameter more than 4mm | 1st stainless steel cylinders |

| Earthworm cocoons | 2~4mm | 2nd perforated plate |

| Vermicompost | 1.5~2mm | 3rd nti-blocking wire mesh screen |

| Soil and other impurities | Less than 1.5mm | Undersized |

vermiculture separator machines types

As a leading supplier of sieving machine in China, DELI supply four types of separators for vermicultrure farming industry: Side vibratory sifter, Circular vibro sifter, Linear vibrating sieving machine, Trommel screener.The following are their technical data and features:

| Data | Side Type | Circular Type | Linear Type | Trommel Type |

| Material | SS304 | SS304 | SS304 | SS304 |

| Sieve Size / mm | Dia. 1000 | Dia. 1000 | 800*3000 | Dia. 800 |

| Mesh size | 4mm | 4mm | 4mm | 4mm |

| Screen Layer | 1 | 1 | 1 | 1 |

| Capacity/ ton per hour | 1.5 | 1 | 4 | 2 |

| Power | 0.9 | 0.45 | 1.1 | 1.1 |

| Price | $2200 | $2000 | $3900 | $3500 |

DELI Multipurpose Vermicompost sieving machine

| Material | Contact part SS304 stainless steel |

| Color | Stainless steel part polish |

| Screen Layer | 3 |

| Mesh size | 4mm, 2mm, 1.5mm |

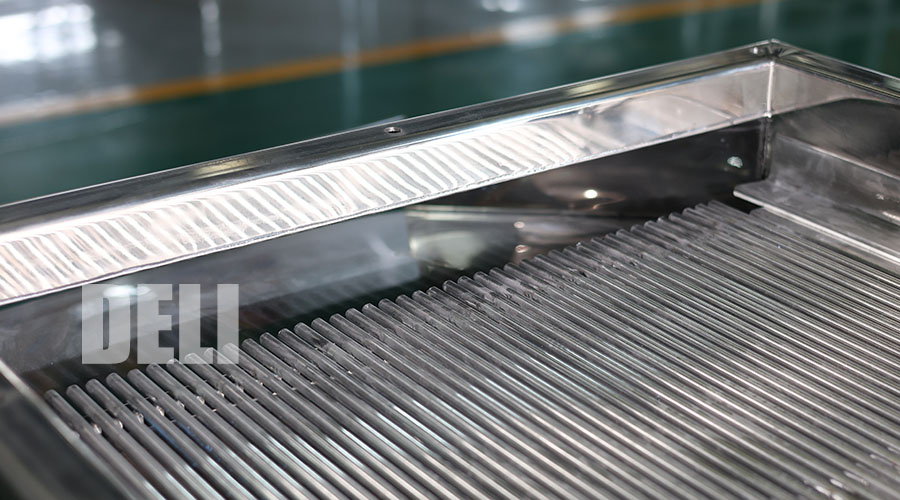

| 1st Screen | SS304 stainless steel bar cylinders |

| 2nd Screen | SS304 stainless steel perforated plate |

| 3rd Screen | SS304 stainless steel perforated plate |

| Voltage | 220V/380V, 50HZ/60HZ, Three phase |

| Motor | Italy OLI brand vibration motor |

| Power | 2 * 0.55KW |

| Motor speed | 960 r/min |

DELI equipment uses a unique composite structure screen to separate vermicompost, and users will benefit from our product:

- Automatic separation. Anti-blocking net design, no manual participation in the cleaning of the screen during the separation process.

- Large output. The screening machine has a variety of sizes to choose from, with a throughput of 1 to 10 tons, suitable for farms of different sizes.

- High separation efficiency. Zero-angle screen, longer separation route and complete separation let customers get pure compost.

- No harm the earthworms. The unique round bar screen has a smooth surface, which avoids cutting earthworms and earthworm larvae, and sustainably uses earthworms to make compost.

- Water corrosion resistance. The equipment is made of high-quality SS304 stainless steel. It will not rust after long-term contact with compost with high water content, and has a long service life.

- Clean. The interior of the equipment adopts a polishing process, the surface is smooth and flat, and it is not easy to leave compost, so as to avoid mold inside the equipment and contaminate the compost and earthworms.

- Easy to maintain. The quick-open design allows customers to quickly access the interior of the equipment without tools, saving maintenance time; the integrated screen plate and screw fixing structure make it convenient for customers to disassemble and clean the screen plate.

- Adjustable amplitude. The vibration force can be adjusted in the range of 0-100%. The farm can easily adjust the amplitude of the screen machine conveniently, thus the sifer can fully adapt to the compost with different characteristics of different farms.

- Safe and convenient electrical control cabinet. The short-circuit protection function is equiped to protect the safety of operators. Inverter is also optional.

- Low noise. The noise within one meter of the equipment is less than 80 decibels, which meets the industrial noise standard and can be placed indoors for use.

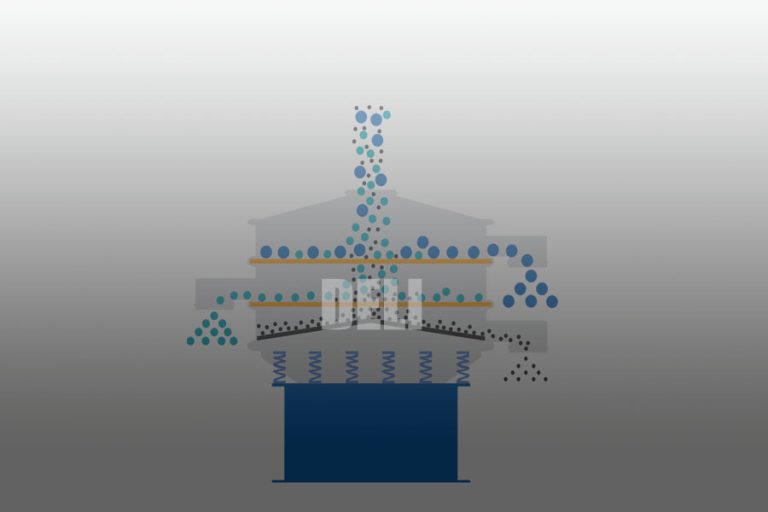

How to sieve vermicompost?

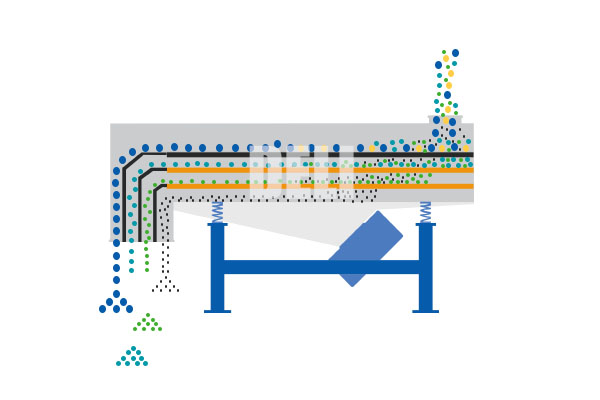

The DELI industrial sieve machine uses the principle of vibration to make the aquaculture raw materials move automatically from the feed port to the discharge port inside the screen. In this process, materials larger than the mesh stay on the screen and are collected, and materials smaller than the mesh pass through the mesh to the next deck, ultimately achieving the purpose of sieving.

Specific sieving process:

The first layer of bar structure screen is used to separate earthworms. It is welded from multiple stainless steel cylinders with a spacing of 4mm between the cylinders. When the raw materials enter the vermicompost sifter, the raw materials move along the bars toward the discharge port. Earthworms with a diameter greater than 4mm will stay above the bars and then move to the No. 1 discharge port. The rest of the materials will enter the second deck through the gap.

The second layer of perforated plate structure screen separates earthworm cocoons. The screen plate is lined with circular holes with a diameter of 2mm. The earthworm cocoons cannot pass through the screen plate and are eventually discharged through the No. 2 outlet. The earthworm manure (compost) enters the third deck through the circular holes.

The third anti-blocking wire mesh screen separates the vermicompost. The mesh size is 1.5mm. The vermicompost with a size larger than 1.5mm is retained on the screen and moves to exit 3. The soil impurity powder passes through the mesh and enters the fourth deck, and is finally collected at exit 4.

How to check the quality of vermicompost?

One of the qualities of compost is purity. The purity of the compost can be judged by observing the content of impurities in the compost after screening. The less impurities such as earthworm cocoons and food residues in the compost, the higher the purity of the compost.