Table of Contents

Briefe introduction

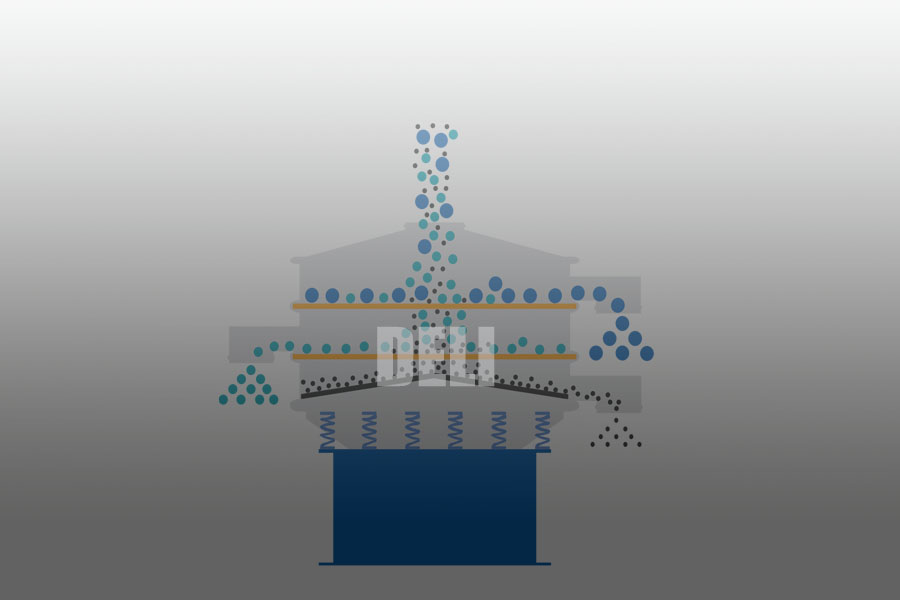

Vibro sieving machine is an industrial equipment that uses the principle of vibration and the difference in particle size to separate. It is mainly used to process dry powders, granules, flake products, and solid-liquid mixtures. I divide the uses of rotary vibrating screen into 3 categories:

| NO. | Use | Particle range | Minimum mesh size | Application Example |

| 1 | Dry Material Scalping | 1~600 mesh | 600 mesh / 20 microns | Flour, starch, washing powder, oatmeal, various powders |

| 2 | Dry Powder Sizing | 1~600 mesh | 600 mesh / 20 microns | Various powders and granules. Chickpeas, protein powder, soy flour, activated carbon, plastic pellets, etc. |

| 3 | Solid/Liquid Mixtures Filtering | 1~600 mesh | 600 mesh / 20 microns | Fermented wine, soy milk, washed plastic sheets, and cow dung recycling. |

1. Dry Powder Sizing:

Multi-layer screening.

Sepration of a variety of solid particles into different size, Up to 6 separations.

For example, flour with 20 to 100 mesh in the flour after grinding. The rotary separator can separate coarser flour of 20 mesh, finer flour of 60 mesh, and ultra-fine flour of 100 mesh. Example model: R1200-3S three deck sieving machine.

Application:

Food Material: soybeans, animal feed, grains, tobacco, teff, instant coffee granules.

Chemical Powder: polystyrene beads, latex, catalyst, casein.

Mining Material: metal powders, tungsten carbide, metallurgy.

Construction: sand, glass beads.

2. Dry Material Scalping:

Remove undesirable oversize particles in a fast process.

After unpacking, part of the woven bag or rope will be incorporated into the product. The circular screener is responsible for filtering out these large-sized impurities. The packaged product does not contain impurities and agglomerates. Example model: R1200-1S one deck sieving machine.

Application:

Food Powder: sugar, spices, starch, flour, salt, powdered milk, chocolate powder.

Chemical Powder: fertilizer, rubber, paint, detergents, latex, catalyst, casein.

Pharmaceutical industry: powdered pharmaceuticals, pharmaceuticals.

Mining: carbon black, carbon black, iron oxide, lead.

Construction: plaster, abrasives Grit/shot, borax.

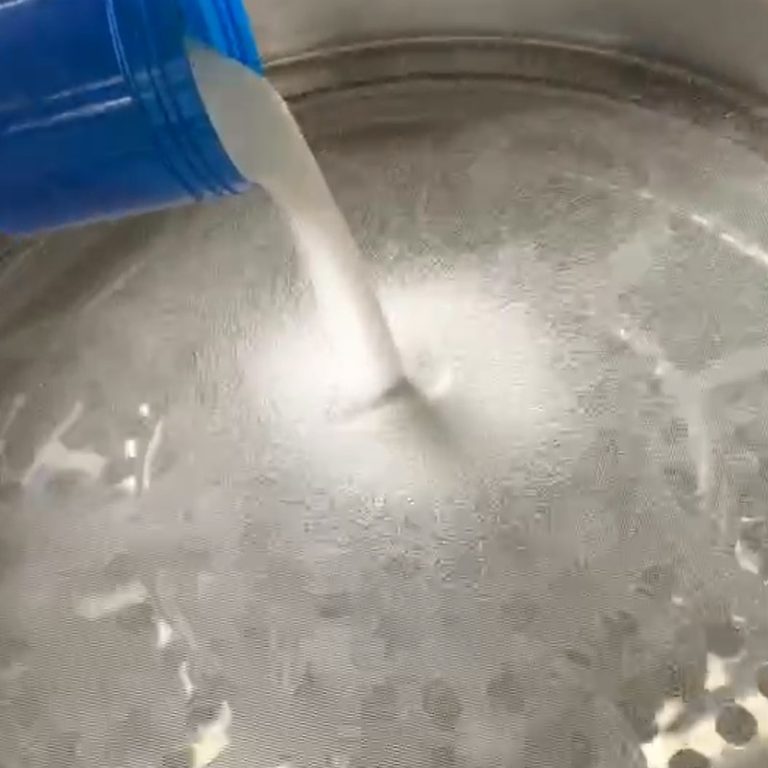

3. Solid-liquid separation

Solid/Liquid Mixtures Filtering:

Filtering oversize solids from all types of slurries, or dewatering solid/liquid mixtures. Collecting usable solids or clarifying liquids.

The fermented wine contains puree and caked impurities, and the round sieve machine is responsible for filtering out the pure puree.

Application:

Fermented wine, soy milk, washed plastic sheets, and cow dung recycling.