A Look at the Benefits and Challenges

The food industry is undergoing a revolution with the introduction of chlorophyll sieving machines. This innovative technology is providing a range of benefits to the industry, while also presenting some challenges. In this article, we will explore the advantages and disadvantages of this technology, and how it is transforming the food industry.

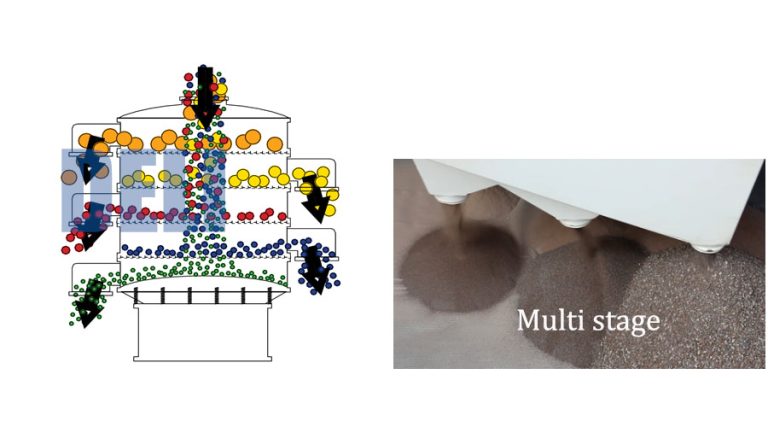

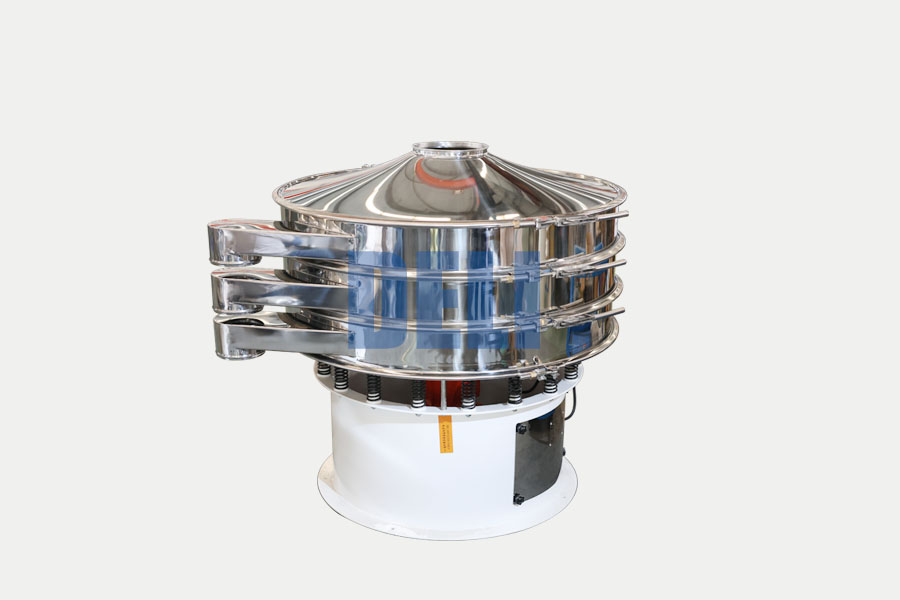

The main advantage of vibro sieving machine is their ability to quickly and accurately separate food particles from other materials. This is done by combining gravity with vibration to separate the particles. This process is faster and more efficient than traditional methods such as manual sorting or screening. Furthermore, these machines are made of food contact grade materials, which ensures that the food is safe to eat.

| Product | Density kg/m³ |

Moist | Mesh size mm | Model NO. | Processing capacity Kg/Hour |

| Wheat starch | 1.0 | Dry | 0.2 | R1500-1 | 2000 |

| Corn starch | 0.6 | Dry | 0.425 | R1000-1 | 1600 |

| Rice flour | 0.5~0.8 | Dry | 0.15 | R1000-1 | 300 |

| Skimmed milk powder | 0.58~0.7 | Dry | 0.8 | R1200-1 | 2500 |

| Salt | 1.2 | Dry | 0.6, 0.18 | R1500-2 | 3000 |

Another advantage of chlorophyll sieving machine is their ability to reduce waste. Reduce the proportion of waste materials and improve the yield rate through efficient screening. This is good for both the environment and the food industry because it reduces scrap rates in the production process.

However, there are some challenges with using a chlorophyll screener. One of the main problems is that the machines are made of expensive stainless steel, it is stainless steel sieving machine, which increases costs for food manufacturers. Additionally, these machines incur maintenance costs as they require regular cleaning and maintenance.

Despite these challenges, chlorophyll screening machines are revolutionizing the food industry. By providing faster, more efficient powder separation solutions, these machines help reduce waste and ensure food is safe to eat. Additionally, these machines help reduce the amount of energy used in the production process. As technology continues to improve, it is likely that the food industry will continue to benefit from the use of chlorophyll screens.