R1000 vibration sieve with screw conveyor

Introduction:

The vibrating screen system consists of a feeding screw conveyor, a vibration sieve machine, and a discharging screw conveyor. It can automatically feed, screen, and convey finished products to silos or packaging equipment.

This is a screening and conveying solution.

All equipment is made of SS304 stainless steel and can handle food powders and granules.

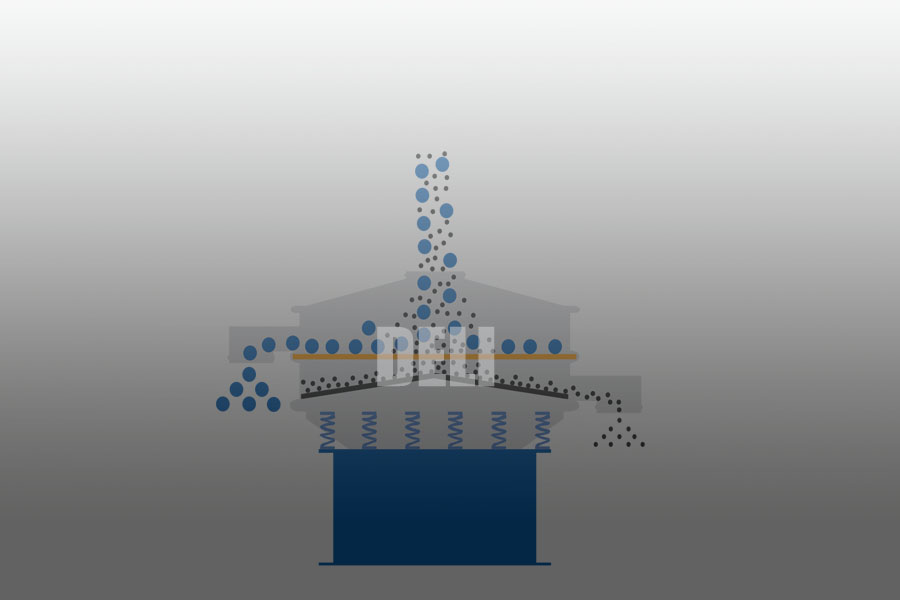

Working principle diagram

Features:

Customized dimension, fully match the upstream and downstream equipment.

Made of SS304 stainless steel.

Automaticly feed and discharge product.

Tell 5~100 mesh (150 microns to 4000 microns).

Specifications

| Material: | SS304 Stainless steel |

| Color: | Polish |

| Screen layer: | 1 |

| Outelet: | 2 |

| Screen diameter: | 1000mm / 40 inch |

| Mesh: | SS304 Stainless steel wire mesh |

| Mesh size: | 5~100 mesh, 0.15~4mm |

| Mesh cleaning: | Bouncing ball |

| Voltage: | 380~690v, 50/60hz, three phase |

| Bearing: | OLI |

| Power: | 0.4Kw*2 |

| Rotate speed: | 1400 Rpm |

| Max Inlet: | 2 tons per hour (powder, bulk desity 0.8, 1mm mesh size) |

Product brochure download

Direct discharge rotary separator

Drawing of sifter and conveyor

Application:

Food powder, medicine, chemical industry, mining, recycling industry.

Dry powder. Flour, starch.