R1200 Direct discharge rotary separator

Introduction:

R1200 is a round shape industrial powder sieving machine. Diameter 48 inches, 1 deck screen. Its undersize discharge port faces downwards, which greatly increases the processing capacity of the vibrating screen. It is very suitable for processing flour.

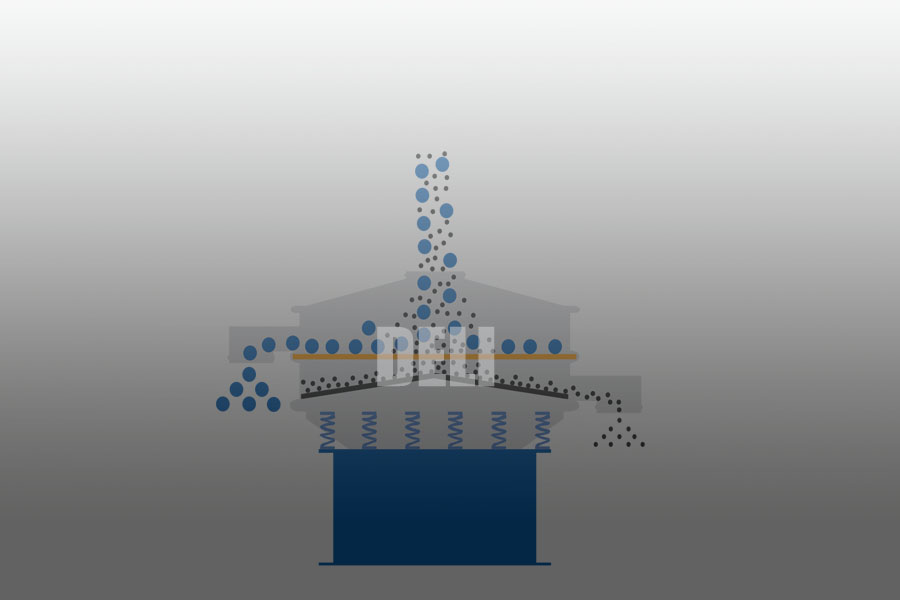

Because the movement trajectory of the product on the screen surface spreads from the center to the surroundings, and then rotates along the circle, it is called a circular screener or a gyro screener.

Its biggest feature is that it is flexible to use and can handle various dry powders, granules, and slices. The product particle size range is 5 to 200 mesh (75 microns to 5000 microns).

Working principle diagram

Features:

Capacity up to 7 tons per hour.

Self cleaning system.

Quickly change screens.

Heavy duty, 7*24 hours running.

Tell 5~200 mesh (75 microns to 5000 microns).

Specifications

| Material: | SS304 Stainless steel + Q235 carbon steel |

| Color: | Sand blast |

| Screen layer: | 1 |

| Outelet: | 2 |

| Screen diameter: | 1200mm / 48 inch |

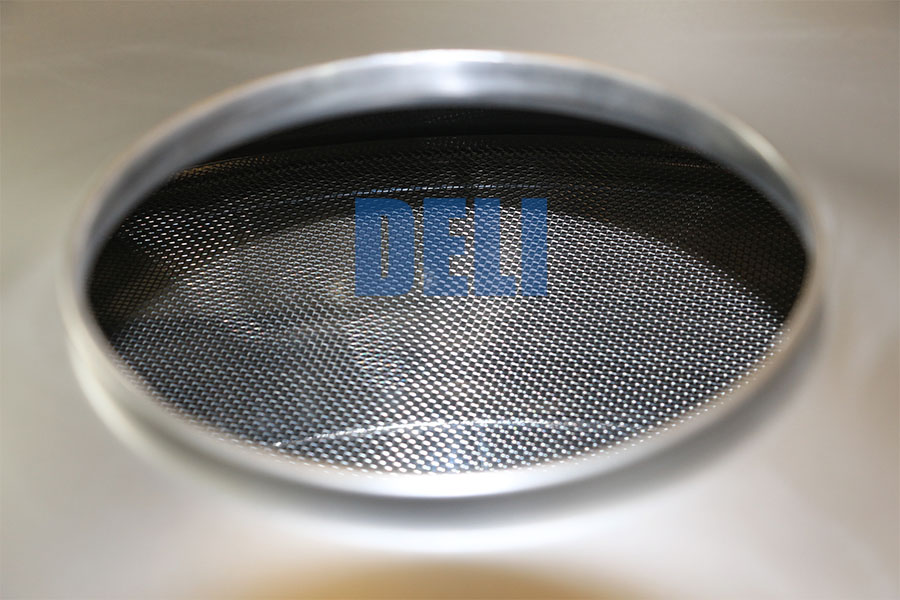

| Mesh: | SS304 Stainless steel wire mesh |

| Mesh size: | 3~200 mesh, 0.075~6mm |

| Mesh cleaning: | Bouncing ball |

| Voltage: | 380~690v, 50/60hz, three phase |

| Bearing: | OLI |

| Power: | 0.4Kw*2 |

| Rotate speed: | 1400 Rpm |

| Max Inlet: | 5 tons per hour (powder, bulk desity 0.8, 1mm mesh size) |

Product brochure download

Direct discharge rotary separator

Application:

Food powder, medicine, chemical industry, mining, recycling industry.

Dry powder. Flour, starch.